Are you navigating the complexities of supplier pricing and looking for ways to enhance your procurement strategy? Understanding competitive pricing analysis can unlock incredible opportunities for your business, allowing you to make more informed decisions. In this article, we'll delve into the essential steps for evaluating supplier pricing, ensuring you get the best deal without compromising on quality. So, let's dive in and explore how you can optimize your procurement processes!

Supplier Details and Background

Supplier details include company name, location (city-state-country), establishment year, and market focus. Background information highlights the supplier's history (how long they have operated), industry experience (specific sectors served), and reputation (customer feedback, awards). Competitive pricing analysis examines pricing structures in relation to similar suppliers in the market. This includes assessment of cost per unit, minimum order quantities, payment terms, and discounts for bulk purchases. Understanding these aspects helps gauge the supplier's competitiveness and positions them within the broader market landscape.

Price Comparison and Breakdown

Conducting a thorough price comparison and breakdown is essential for evaluating supplier offers in the competitive market of manufacturing. Understanding pricing structures, including unit costs, bulk discounts, shipping fees, and any additional charges, provides a clear view of overall expenses. For instance, a supplier might offer a base price of $2.50 per unit for an order of 1,000 items, but additional shipping charges of $200 can affect the total expenditure. Different suppliers may have variations in pricing based on lead times, quality of materials, and payment terms, which should also be critically assessed. Furthermore, analyzing suppliers from regions such as Southeast Asia or Eastern Europe can yield significant savings due to lower labor costs, though factors like shipping logistics and tariffs must also be calculated into the final cost. Such detailed evaluations are vital for making informed procurement decisions and achieving the best value for the company's needs.

Quality and Value Assessment

The competitive pricing analysis serves as a critical evaluation tool in the procurement process, specifically focusing on quality and value. Various suppliers, including industry leaders like ABC Manufacturing and XYZ Components, have provided their quotes for similar product categories, such as electronic components and raw materials. Key factors such as cost per unit (ranging from $5 to $20), minimum order quantity (typically between 100 to 1,000 units), and delivery timelines (averaging 2 to 4 weeks) were assessed. Additionally, product quality was evaluated using established benchmarks like ISO 9001 certification and customer satisfaction ratings, with scores noted between 4.0 to 4.8 out of 5. This analysis aims to identify the supplier who offers the best combination of competitive pricing and high-quality materials, ensuring optimal value for the organization's procurement strategy.

Market Analysis and Trends

A competitive pricing analysis involves evaluating the pricing structures of suppliers in a particular industry. Market segments such as electronics, textiles, or food services provide valuable insights. Key trends include the impact of inflation rates, which reached an average of 8% in 2022, influencing cost adjustments. Geographic factors also play a role; for instance, suppliers based in Southeast Asia may offer lower prices due to reduced labor costs, while European suppliers might reflect higher standards and certifications affecting their pricing. Understanding customer demand shifts, such as the recent increase in sustainability preferences, can guide pricing strategies and enhance competitive positioning. Keeping track of competitor pricing changes is essential for maintaining market relevance.

Negotiation and Partnership Opportunities

Competitive pricing analysis reveals significant variances among suppliers impacting procurement strategies in the automotive sector. Recent data shows that reputable suppliers in regions such as Southeast Asia and Eastern Europe offer competitive rates, with price differentials averaging 15% compared to North American providers. These disparities can influence overall project budgets significantly, prompting companies to explore negotiation opportunities. Establishing strategic partnerships with suppliers can enhance supply chain efficiency and mitigate risks associated with price fluctuations. Engagements in dialogues focusing on long-term contracts (often spanning over three to five years) can yield favorable terms and stability in pricing, fostering mutual benefits for both parties involved. Additionally, exploring volume-based discounts might further reduce costs while ensuring quality and timely delivery in the ongoing competitive landscape.

Letter Template For Supplier Competitive Pricing Analysis Samples

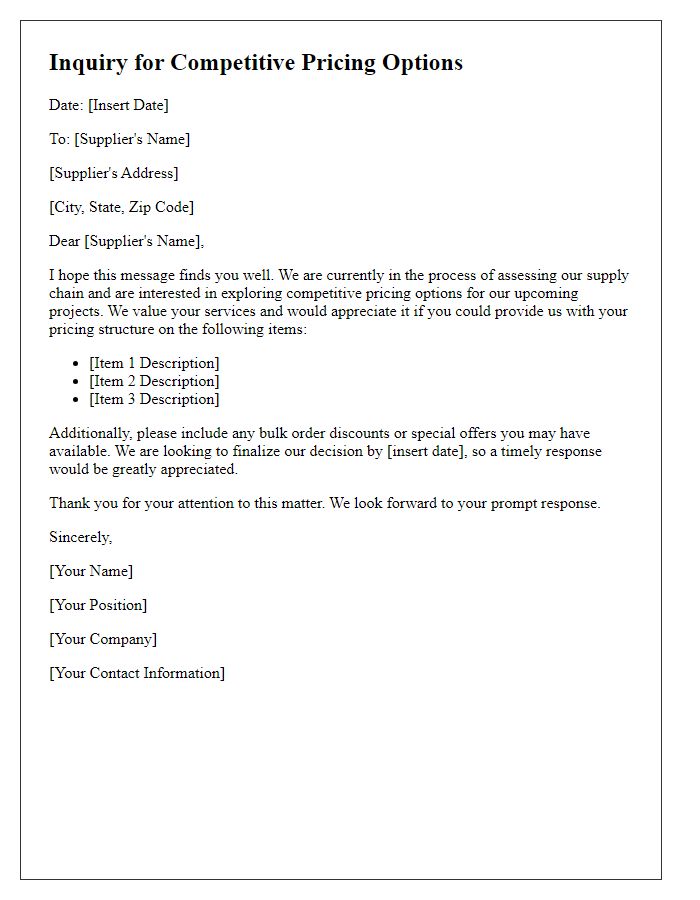

Letter template of inquiry for competitive pricing options from suppliers.

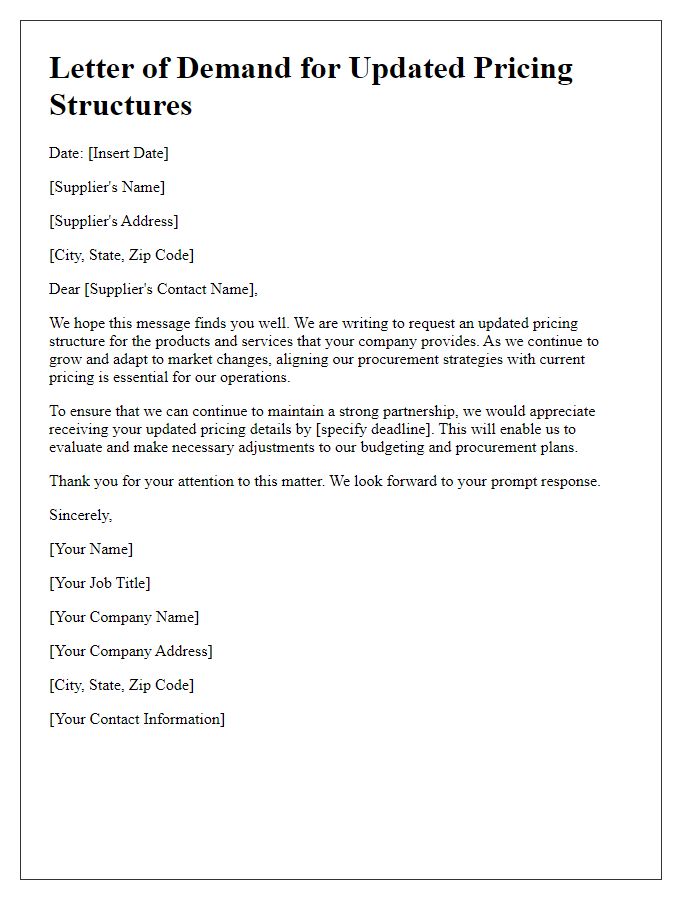

Letter template of demand for updated pricing structures from suppliers.

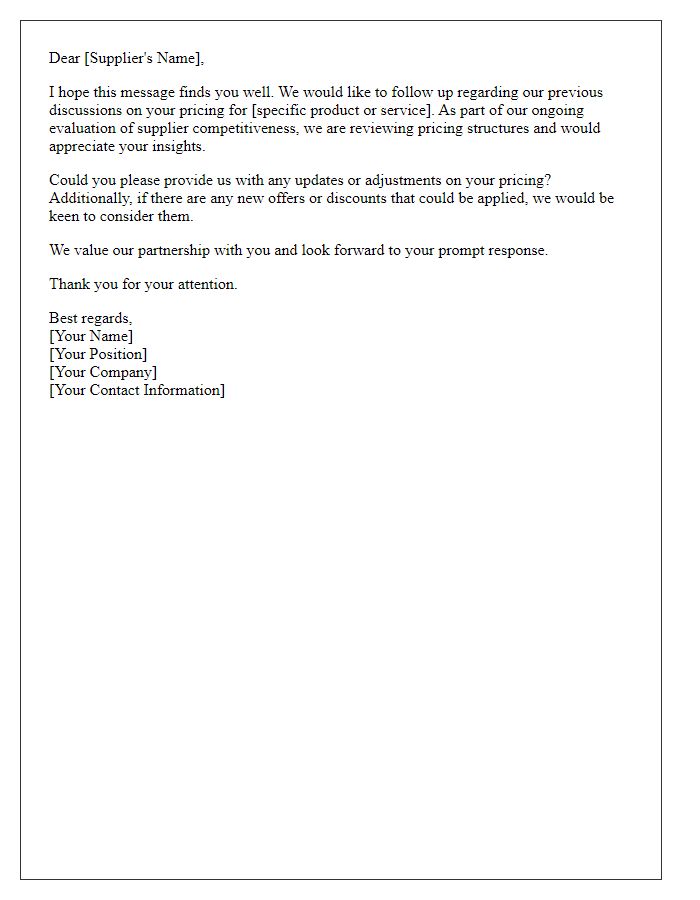

Letter template of follow-up for supplier pricing competitiveness evaluation.

Letter template of assessment request for supplier pricing efficiencies.

Letter template of appeal for transparency in supplier pricing strategies.

Comments