When it comes to ensuring safety in the workplace, having a well-defined emergency shutdown procedure is absolutely critical. This systematic approach not only helps you respond swiftly during a crisis but also minimizes risk and protects your team and assets. Understanding the importance of clear communication in such situations can make all the difference in maintaining order and safety. If you'd like to delve deeper into crafting an effective emergency shutdown letter, read on!

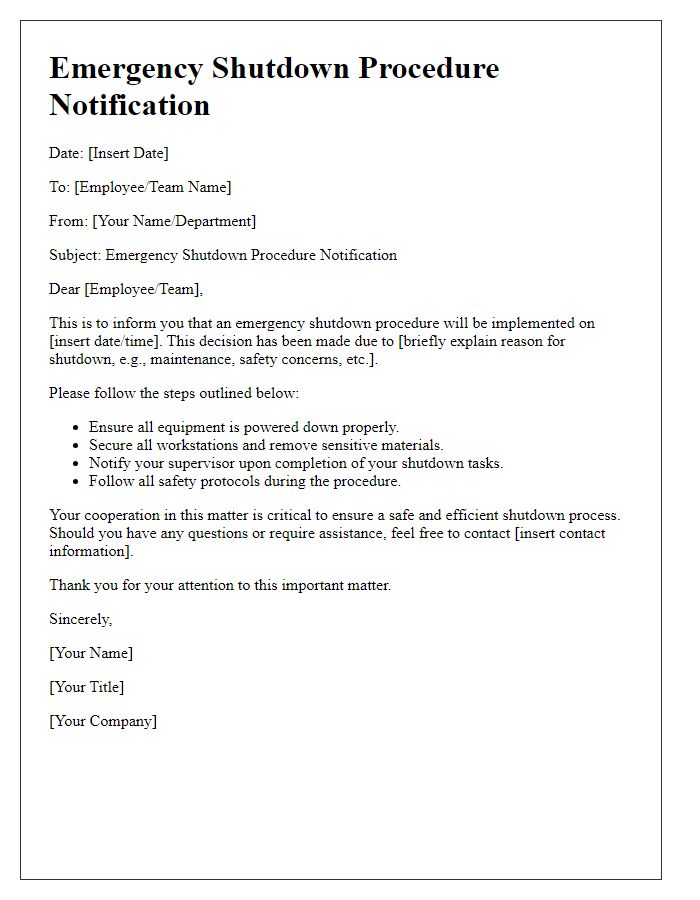

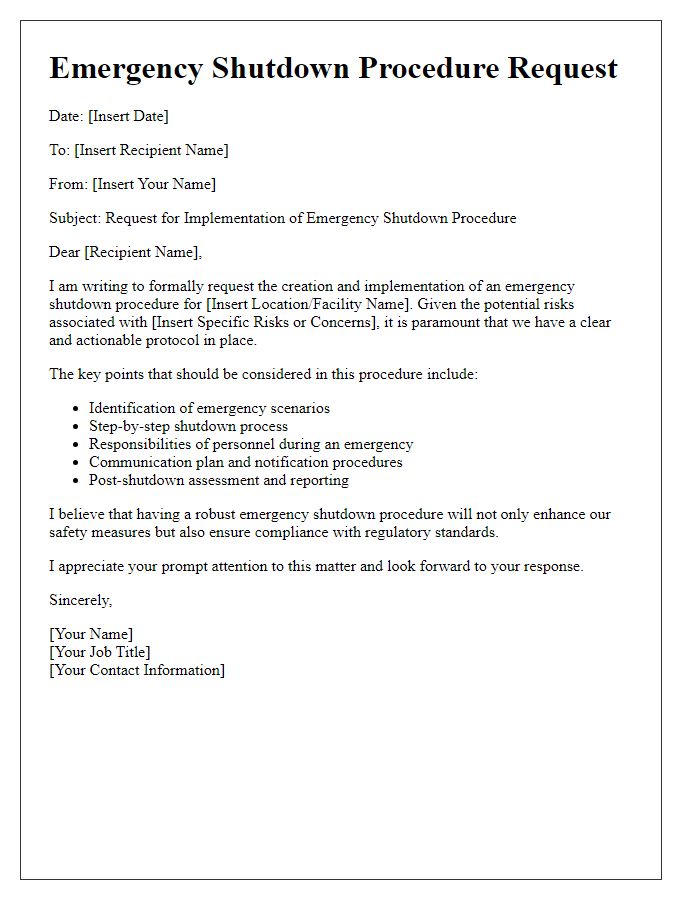

Subject Heading with Urgency Indicator

An emergency shutdown procedure is critical for ensuring the safety and efficiency of operations within industrial environments, particularly in facilities like chemical plants or nuclear power stations. This procedure involves a series of predefined steps that must be executed swiftly to minimize risks associated with equipment failures or hazardous situations. Key components include the immediate identification of the emergency (e.g., fire, gas leak), activation of alarm systems, and notifying appropriate personnel, such as safety officers or external emergency services. Detailed instructions on isolating power (usually within seconds) and shutting down machinery must be readily accessible in the control room, aiding operators in performing rapid shutdowns under high-stress conditions. Regular drills and training sessions should reinforce these procedures, ensuring all team members remain adept at effectively executing emergency protocols.

Clear Description of Shutdown Reason

Emergency shutdown procedures are critical for ensuring the safety and integrity of operations within industrial environments, such as manufacturing plants or nuclear facilities. Each reason for shutdown, whether it is equipment failure, hazardous material leak, or unsafe working conditions, must be clearly documented and communicated. For instance, an emergency shutdown may be initiated due to a detected drop in pressure below the critical threshold of 20 psi in a gas pipeline, indicating a possible rupture. Similarly, a dangerous chemical spill greater than 5 liters of a toxic substance like hydrochloric acid requires immediate intervention. The shutdown process involves several key steps, including notification of personnel via alarms, isolation of power sources, and implementation of containment measures to prevent further escalation of the incident. Documenting each reason thoroughly supports future investigations and ensures compliance with safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) or the Environmental Protection Agency (EPA).

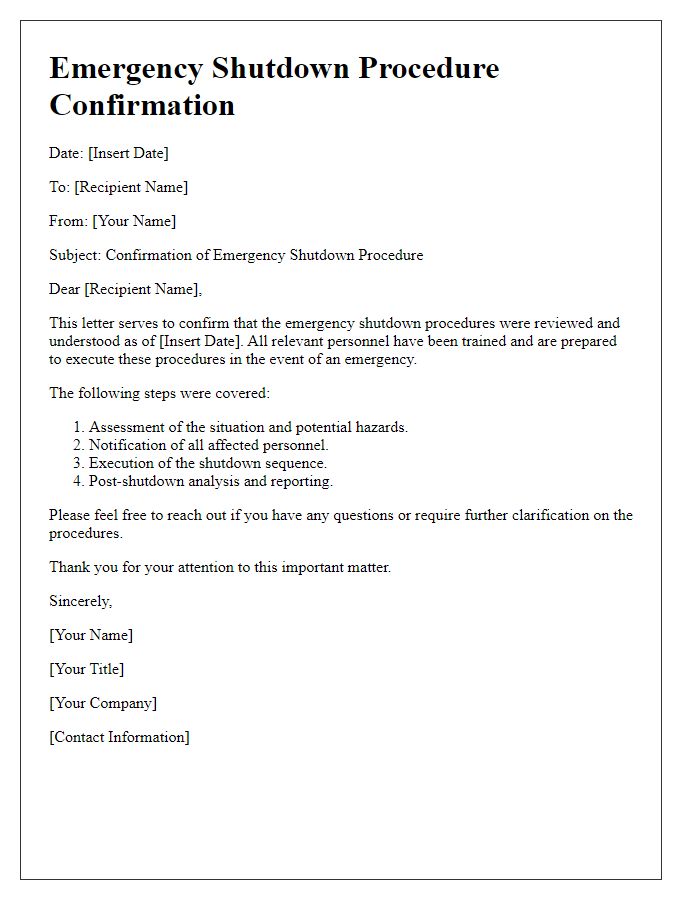

Step-by-Step Shutdown Instructions

In emergency situations, following a detailed shutdown procedure is crucial for ensuring safety and equipment integrity. The first step involves notifying all personnel within the facility, such as the operations manager or team leaders, of the imminent shutdown. Next, convene at designated safety assembly points, ensuring everyone is accounted for. Proceed to secure critical machinery, for example, shutting down hydraulic systems or stopping conveyor belts. Then, power down essential electrical systems in the correct sequence to prevent damage; for instance, turn off emergency lighting and backup generators last. Finally, ensure all hazardous materials are contained, following the protocol established in the Material Safety Data Sheets (MSDS), and prepare for a post-shutdown assessment to evaluate and document any issues encountered during the procedure.

Contact Information for Responsible Personnel

In an emergency shutdown scenario, immediate access to responsible personnel is crucial for effective response. Key contacts include the Safety Officer, currently John Smith, who can be reached at (555) 123-4567. The Operations Manager, Sarah Johnson, oversees the procedural aspects and is available at (555) 234-5678. Additionally, the Facility Manager, Mike Brown, responsible for physical site safety, can be contacted at (555) 345-6789 during business hours. It is also essential to have a designated Emergency Response Team Leader, Amanda Lee, reachable at (555) 456-7890, to coordinate all emergency operations on-site. These contacts are vital to ensure swift communication during any emergency shutdown protocol.

Reopening or Follow-up Details

Emergency shutdown procedures are critical protocols activated when a significant threat or hazard occurs in facilities, such as nuclear power plants or chemical processing plants. These protocols ensure that systems like cooling towers and emergency generators are engaged promptly. Effective communication detailing reopening procedures follows an emergency shutdown. This includes confirming the operational status of safety systems, such as fire suppression systems and alarm notifications. Follow-up details involve conducting thorough inspections of affected machinery, ensuring compliance with regulatory bodies like the Occupational Safety and Health Administration (OSHA) or the Environmental Protection Agency (EPA). Documentation verifying safety checks and employee readiness for re-engagement is crucial, emphasizing training on potential hazards. These measures maintain workplace safety and secure environmental integrity during and after emergency scenarios.

Comments