Are you looking to enhance your quality control processes but unsure where to start? Crafting an effective letter for a quality control review can make all the difference in streamlining your efforts and improving overall outcomes. In this article, we'll explore essential components to include in your letter, as well as tips to ensure your message resonates with your team. Join us as we delve deeper into creating impactful communication that drives quality excellence!

Company Header

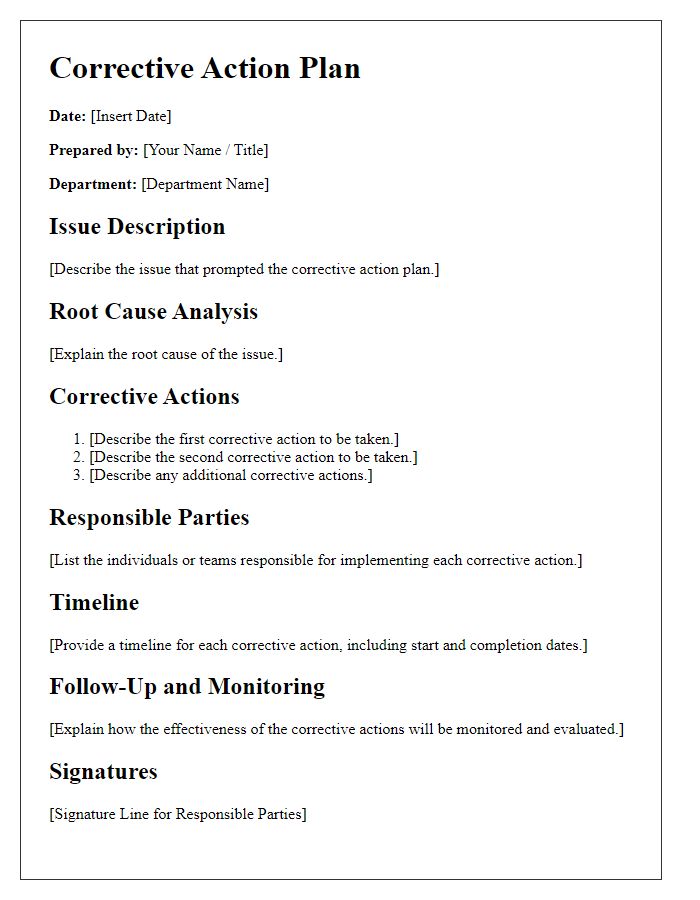

Quality control review processes are essential for maintaining high standards within organizations. These processes often include systematic inspections and evaluations of products, such as electronics or automotive parts. Documentation plays a crucial role, often requiring detailed notes on measurements, defects, and compliance with industry standards, such as ISO 9001. In a typical quality control review, various metrics, including defect rates (often targeted below 1%) and inspection times, are analyzed to ensure optimal performance and customer satisfaction. Additionally, corrective actions must be documented, highlighting necessary improvements or adjustments based on review findings. Effective quality control not only enhances product reliability but also builds trust with stakeholders in competitive markets.

Date

The quality control review process plays a critical role in maintaining product standards in manufacturing and service delivery. Regular assessments conducted on specific dates, such as quarterly reviews, focus on key performance indicators including defect rates (ideally below 1%), customer complaints (tracked weekly), and compliance with ISO 9001 standards. The review often occurs in dedicated meeting rooms within corporate headquarters, where cross-functional teams analyze data collected from production facilities, such as those based in Detroit (notable for the automotive industry) and Shanghai (a hub for electronics manufacturing). Recommendations arising from these reviews aim to enhance operational efficiency, reduce waste, and ensure continuous adherence to regulatory requirements, thereby fostering customer satisfaction and trust.

Recipient Information

Quality control reviews are essential for maintaining product standards in manufacturing processes. Effective communication with recipients--such as quality assurance managers, production supervisors, and compliance officers--plays a crucial role in this process. Critical components of recipient information may include full names, job titles, department affiliations, and specific locations within organizations, such as factory floors or corporate offices. Additional details like email addresses, phone numbers, and preferred communication methods can further streamline the review process, ensuring that all necessary feedback is gathered promptly and effectively. Thorough recipient data helps facilitate clear and organized correspondence, enhancing collaboration during quality assessments and ensuring that standards are met consistently.

Subject Line

Quality Control Review Process Overview: Key Insights and Recommendations Quality control processes ensure product standards, focusing on manufacturing protocols, inspection methods, and defect management. Regular audits (conducted quarterly) assess adherence to guidelines, identifying areas for improvement. Analysis of defect rates (averaging 5% across various product lines) provides insights into recurring issues. Implementing corrective actions enhances efficiency, reducing rework costs (estimated at $50,000 annually). Stakeholder engagement, including feedback from frontline employees, creates a collaborative environment, fostering innovation. Documenting findings in a centralized database enhances transparency and facilitates ongoing training initiatives, ensuring quality standards remain robust.

Introduction and Purpose Statement

Quality control review processes play an essential role in ensuring product consistency and adherence to industry standards. The primary purpose of this review is to evaluate the current systems and practices utilized in monitoring quality metrics, identifying non-conformities, and implementing corrective actions. This assessment seeks to enhance operational efficiency, minimize defects, and promote customer satisfaction across various sectors, especially manufacturing and service industries. Emphasis on Continuous Improvement (CI) methodologies will underpin the review, empowering teams to maintain high-quality deliverables and foster an environment of accountability and excellence.

Comments