Hello there! In today's fast-paced business environment, it's crucial to keep our inventory management practices up to date, especially when it comes to addressing inventory obsolescence. We understand that a clear policy can significantly streamline operations and reduce financial risks associated with outdated stock. So, grab a cup of coffee and join me as we delve deeper into the ins and outs of our updated inventory obsolescence policy. Let's explore how these changes can benefit our organization together!

Objective Clarity

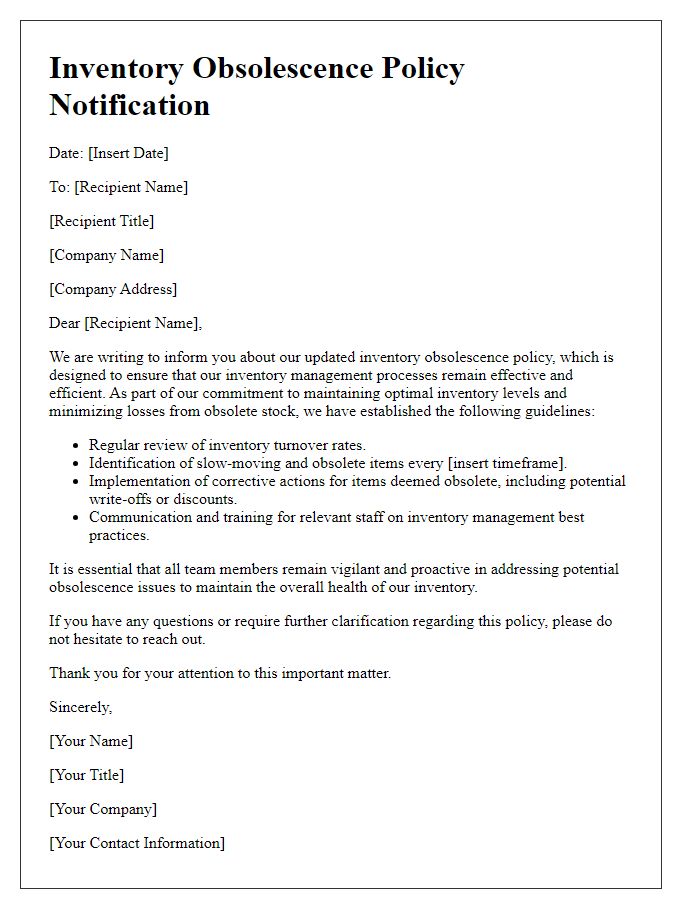

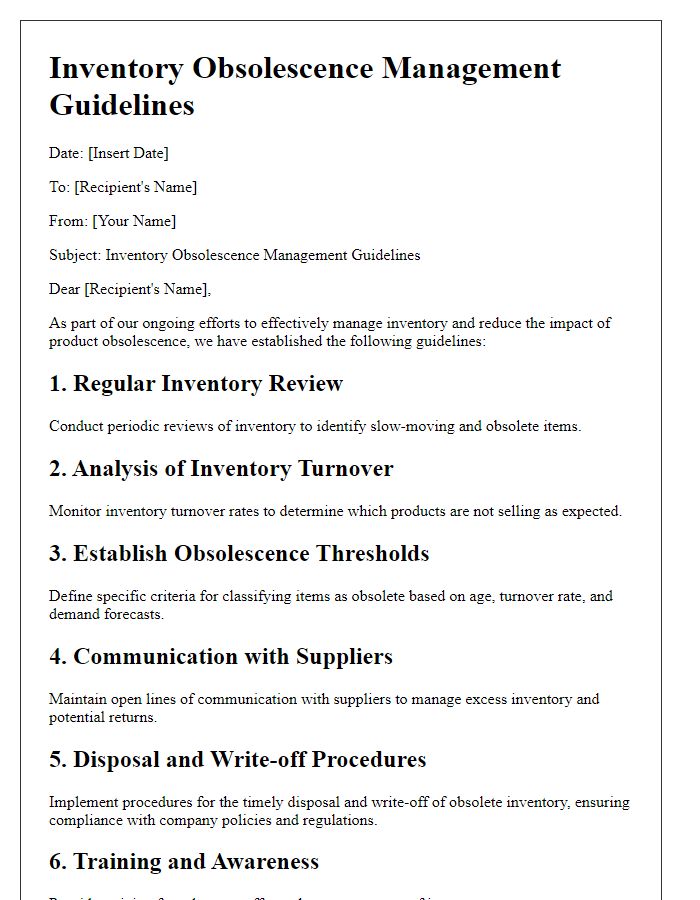

An inventory obsolescence policy update is essential for maintaining operational efficiency in supply management. Obsolescence occurs when items are no longer sellable or usable, often due to technological advancements or changes in consumer preferences. Companies, particularly in the retail and electronics sectors, should regularly review and categorize their stock, assessing items for sales velocity and market relevance. This process, which may involve metrics such as turnover rates and projected demand forecasts, can lead to informed decisions about markdown strategies or disposal methods. Implementation of this updated policy not only minimizes financial losses but enhances warehouse space optimization, ensuring resources are allocated effectively to high-demand inventory.

Obsolescence Criteria

Obsolescence criteria in inventory management refer to the specific guidelines used to determine when products become outdated or unsellable. Common factors include the duration of storage, such as products not moved for over 12 months, product condition assessments for items showing signs of deterioration, technological advancements that render certain items less desirable, and market demand fluctuations that affect sales velocity. Businesses must also consider seasonal trends, especially in industries like fashion or electronics where styles and models change rapidly, leading to stock becoming obsolete. Implementing precise obsolescence criteria assists in maintaining an efficient inventory system, reducing excess stock, and ensuring financial health through timely write-offs or discounts.

Review Frequency

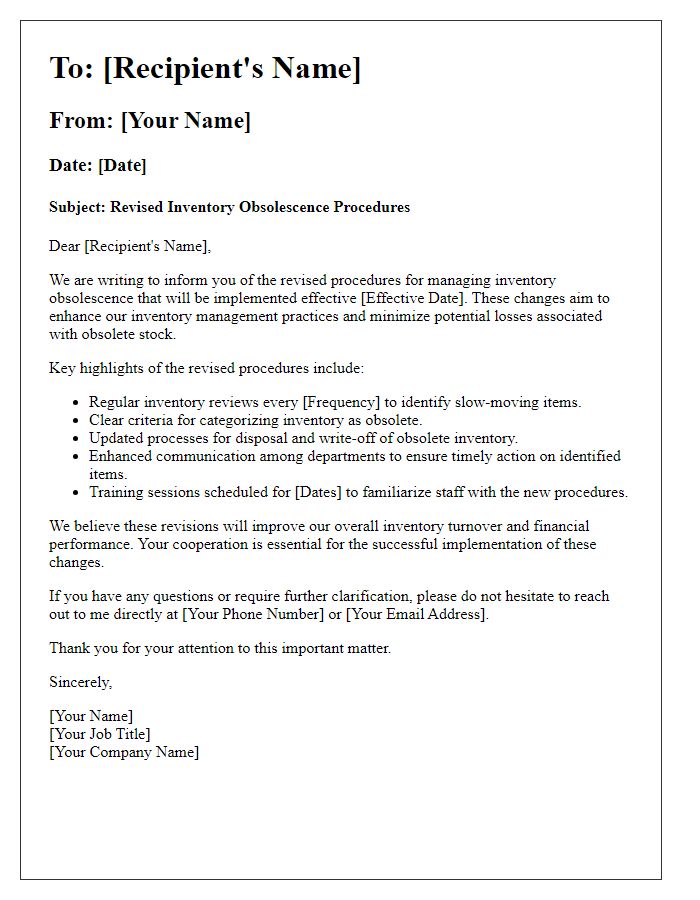

An inventory obsolescence policy encompasses guidelines for managing stock items that are no longer sellable or usable due to factors such as market changes, technological advancements, or product life cycles. Regular review frequency is vital for effective inventory management, typically conducted quarterly (every three months). This ensures timely identification of obsolete items, enabling proactive decision-making. Specific metrics, such as sales velocity and turnover rates, can inform this review process, highlighting items that haven't sold in the past 12 months. Implementing these reviews in a structured manner can significantly reduce storage costs and free up capital for more profitable inventory items. All findings and recommended actions should be documented for future reference and accountability in maintaining optimal inventory levels.

Financial Implications

Inventory obsolescence occurs when goods held in stock lose their value or utility over time, impacting a company's financial statements. Specific financial implications include increased costs associated with storage and insurance for outdated inventory, leading to an overall rise in overhead expenses. In 2022, companies reported an average inventory turnover ratio of 5, underscoring the importance of timely stock rotation. Additionally, organizations may need to write down the book value of obsolete products, resulting in reduced net income and potential tax consequences. Effective inventory management strategies can mitigate these issues, enhancing cash flow and sustaining profitability in competitive markets.

Stakeholder Responsibility

Stakeholders hold pivotal roles in the management of inventory obsolescence, particularly in retail and manufacturing sectors. Various departments, such as Supply Chain Management, Finance, and Operations, must actively engage to identify slow-moving items. Regular assessments, ideally quarterly, assist in recognizing products that have not sold for over six months, which can lead to potential write-offs. Decisions regarding disposal, markdown, or donation must be documented and agreed upon, promoting accountability. Training sessions for teams must occur annually to ensure understanding of new policies and best practices surrounding inventory management. Implementation of a dedicated inventory management software can streamline tracking, enabling stakeholders to make informed decisions based on up-to-date data.

Comments