Are you looking to ensure that your vendors meet the highest quality standards? Crafting a well-structured quality assurance request letter can be the key to maintaining strong relationships and guaranteeing product excellence. In this article, we'll guide you through the essential components of a vendor quality assurance request, making it easier for you to communicate your expectations effectively. Dive in to discover tips and templates that will help streamline your vendor communications!

Clear Request Details

A vendor quality assurance request outlines specific expectations regarding product quality and compliance standards, tailored to ensure smooth collaboration between businesses. Key aspects include clear metrics for quality assessment, such as defect rates (targeting less than 1% for manufacturing defects), products specifications (dimensions and materials), compliance with industry standards (ISO 9001 certification), and timelines for delivery (e.g., 30-day lead time). Additionally, the request should incorporate processes for handling non-conformance, including corrective action plans, reporting mechanisms, and regular quality audits. Communication frequencies must be established, like weekly status updates on quality assessments. This structured approach enhances accountability and ensures mutual understanding of quality expectations.

Vendor Contact Information

Effective vendor quality assurance is crucial for maintaining product standards and ensuring customer satisfaction. The vendor contact information should include detailed entries such as company name, complete address (including city, state, and zip code), primary contact person's name, job title, phone number, and email address. Additionally, including the vendor's business registration number and relevant certifications can facilitate trust and compliance with industry standards. This information should be consistently updated to ensure clear communication channels and swift resolution of any quality-related issues encountered during the supply process.

Quality Assurance Requirements

Vendor quality assurance requests focus on ensuring product quality standards are met consistently. Quality assurance (QA) includes processes such as systematic inspections, testing, and adherence to specifications set by industry standards (e.g., ISO 9001). Key aspects include documentation of QA protocols, frequency of quality checks (weekly, monthly), and the roles of personnel involved in these processes. Additionally, performance metrics such as defect rates (ideally below 1%) and customer feedback loops must be outlined to assess overall product quality. Compliance with local regulations and safety standards is essential, especially in sectors like food and pharmaceuticals, where products directly impact consumer health.

Compliance and Standards

To ensure optimal product delivery, organizations must implement rigorous vendor quality assurance protocols. Compliance with industry standards, such as ISO 9001, establishes a framework for maintaining quality management systems. Key metrics, like defect rates and on-time delivery percentages, are crucial for evaluating vendor performance effectively. Documentation regarding compliance, including certificates and audit reports, must be meticulously maintained to demonstrate adherence to regulatory requirements. Regular assessments of vendor practices should be scheduled quarterly, focusing on continuous improvement initiatives to enhance product quality. Moreover, communication channels can facilitate clarity regarding expectations and standards, thus fostering strong vendor relationships.

Deadline for Response

A vendor quality assurance request involves ensuring that products meet specific standards and specifications before delivery. This process often includes a thorough review of materials, production methods, and compliance with industry regulations. Quality assurance teams typically set a deadline for response, such as seven working days after submission, to finalize any necessary adjustments. Establishing deadlines helps in maintaining a smooth supply chain, minimizing delays in production schedules. Effective communication channels should be outlined, including email addresses and contact numbers of quality assurance representatives, to facilitate timely responses. Additionally, documentation such as quality control reports and defect rates may be requested to support the vendor's compliance status.

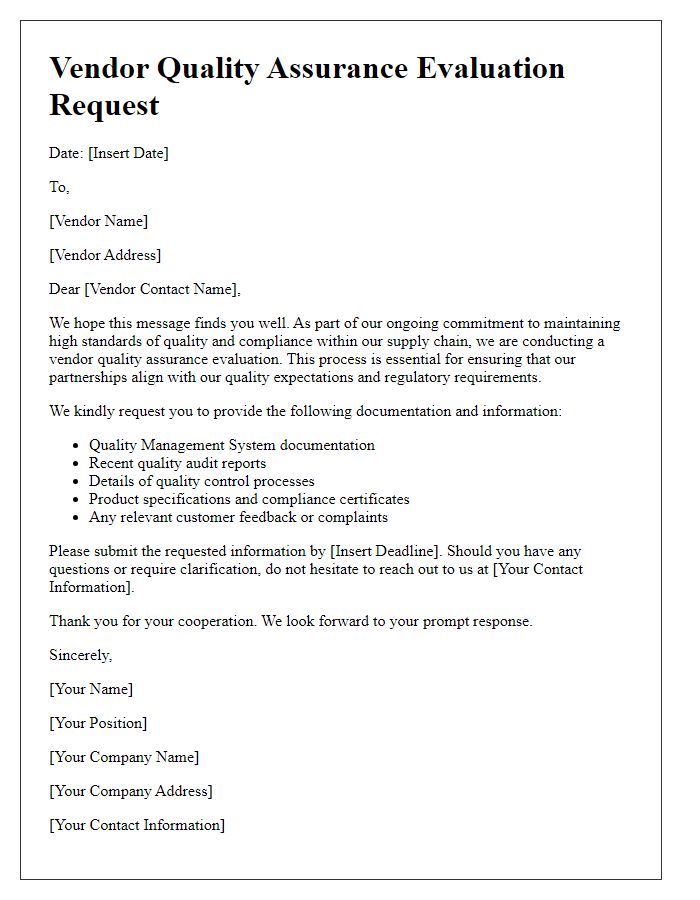

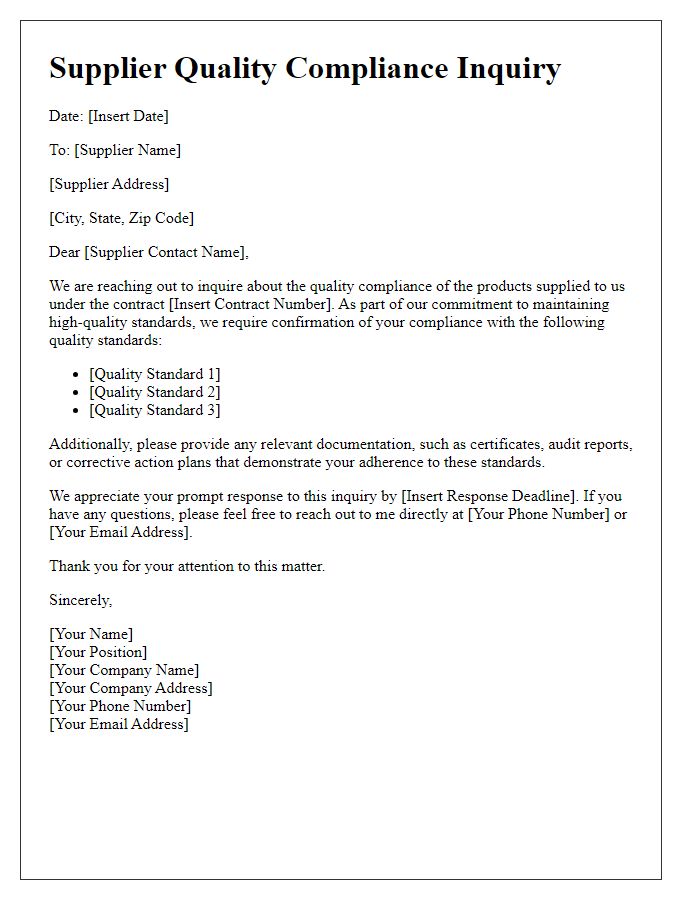

Letter Template For Vendor Quality Assurance Request Samples

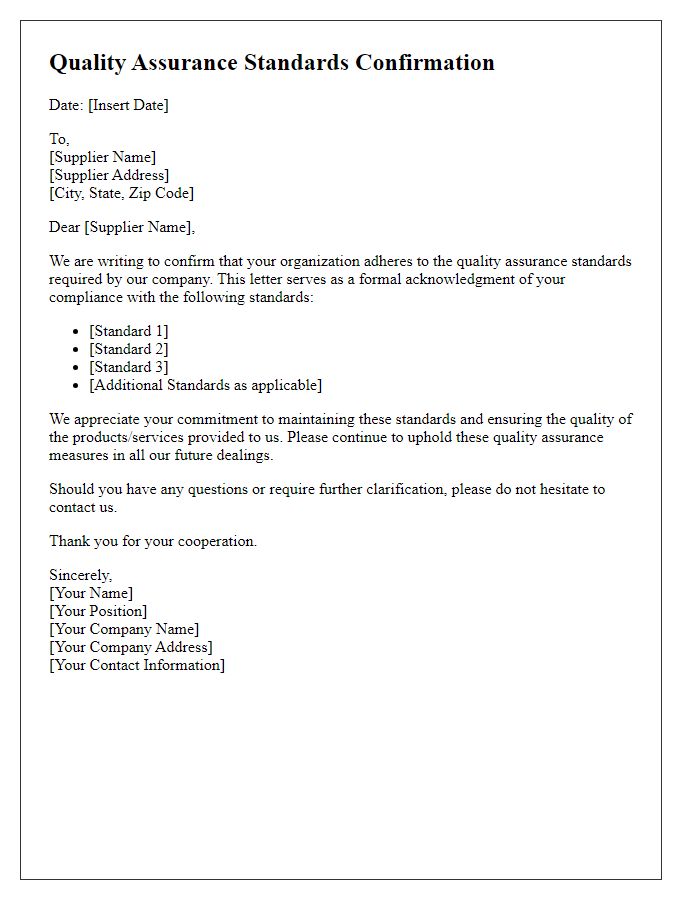

Letter template of quality assurance standards confirmation from supplier

Comments