When it comes to negotiating prices with suppliers, crafting the right letter can make all the difference. Establishing a friendly yet professional tone is key to fostering a productive discussion. In this article, we'll explore effective strategies for writing a negotiation letter that not only conveys your needs but also strengthens your business relationship. Ready to dive into the world of successful supplier negotiations? Let's get started!

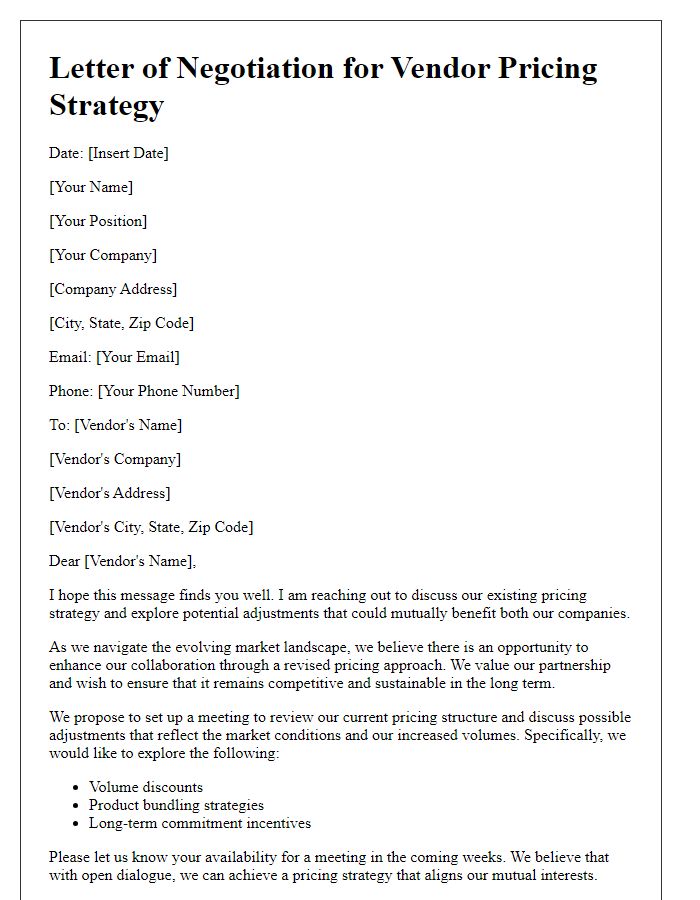

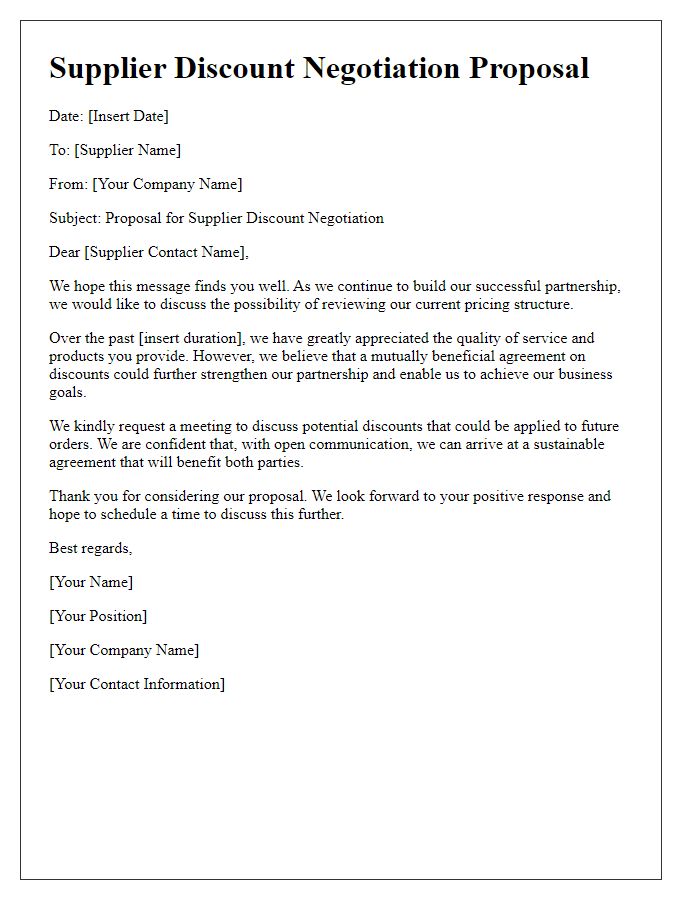

Clear Introduction and Context

In the competitive landscape of supply chain management, understanding supplier pricing strategies is crucial for effective negotiation. Suppliers often present their pricing based on various factors such as production costs, market demand, or operational expenses. Conducting thorough research on industry standards, such as average cost per unit or prevalent pricing trends, can empower a buyer during negotiations. Contextualizing the negotiation within specific events, such as upcoming product launches or seasonal demands, can provide leverage to secure favorable terms. Crafting a precise negotiation strategy that reflects your organization's purchasing volume, financial capability, and relationship history with the supplier can enhance the chances of reaching a mutually beneficial agreement.

Specific Product or Service Details

A supplier price negotiation can yield significant savings for businesses. Focusing on the specific product, such as high-quality custom packaging materials used in retail, is essential. These materials, often made from recycled paperboard or biodegradable plastics, directly impact branding and environmental sustainability. Recent industry trends indicate that the average price per square meter for premium packaging has risen to approximately $3.50, driven by increased demand and supply chain disruptions. Engaging in direct negotiations can leverage volume purchasing, estimated at 10,000 units annually, to secure lower rates while maintaining quality standards. Understanding competitors' pricing models also provides a strategic advantage in negotiations. Ultimately, fostering a strong partnership with suppliers can lead to improved terms, faster delivery times, and enhanced product innovation.

Justification for Negotiation (Market Research and Comparisons)

Market research indicates significant fluctuations in the pricing of raw materials and components, particularly in the manufacturing sector. A recent analysis of supplier pricing trends reveals that comparable suppliers in the industry, such as Supplier A and Supplier B, are offering similar products at approximately 15-20% lower prices, which creates a competitive environment. Additionally, data gathered from industry reports published in Q3 2023 shows a consistent decrease in costs for steel and aluminum, impacting overall pricing strategies. Moreover, economic factors such as a 3% decrease in production costs due to advancements in technology and efficiency improvements further undermine the justification for maintaining higher prices. Therefore, based on this comprehensive market research and competitive analysis, a renegotiation of pricing terms becomes essential to align with prevailing market standards and ensure long-term collaboration.

Proposed New Terms and Pricing

Supplier negotiations often involve discussions regarding terms and pricing adjustments to create a mutually beneficial agreement. Companies like ABC Manufacturing, established in 2005, may approach suppliers with new offers that include reduced prices, payment terms extending to 60 days, and minimum order quantities designed to strengthen business relations. Current market analysis shows that material costs, such as steel and resin, have decreased by 15% over the last quarter, prompting many businesses to revisit existing contracts. This ongoing trend reflects the broader economic landscape and supply chain dynamics, enhancing the importance of favorable pricing structures for sustainable operational strategies.

Call to Action and Contact Information

In the competitive landscape of supply chain management, initiating a price negotiation call to action is vital for achieving favorable terms. Companies should proactively reach out to suppliers such as those providing raw materials, components, or services pivotal to business operations. Clear communication emphasizing mutual benefits can significantly enhance outcomes. Contact details should include specific points of contact, such as procurement managers or financial officers, ensuring prompt engagement. Providing multiple channels for communication, including direct phone numbers or email addresses, facilitates a smooth negotiation process. Aim for collaboration to achieve sustainable pricing while maintaining quality standards.

Comments