Hey there! If you've ever found yourself wondering how to keep your suppliers in the loop about inventory levels, you're in the right place. A well-crafted letter can not only communicate vital information but also strengthen your relationship with suppliers. Ready to explore effective templates and tips to keep those lines of communication open? Let's dive in!

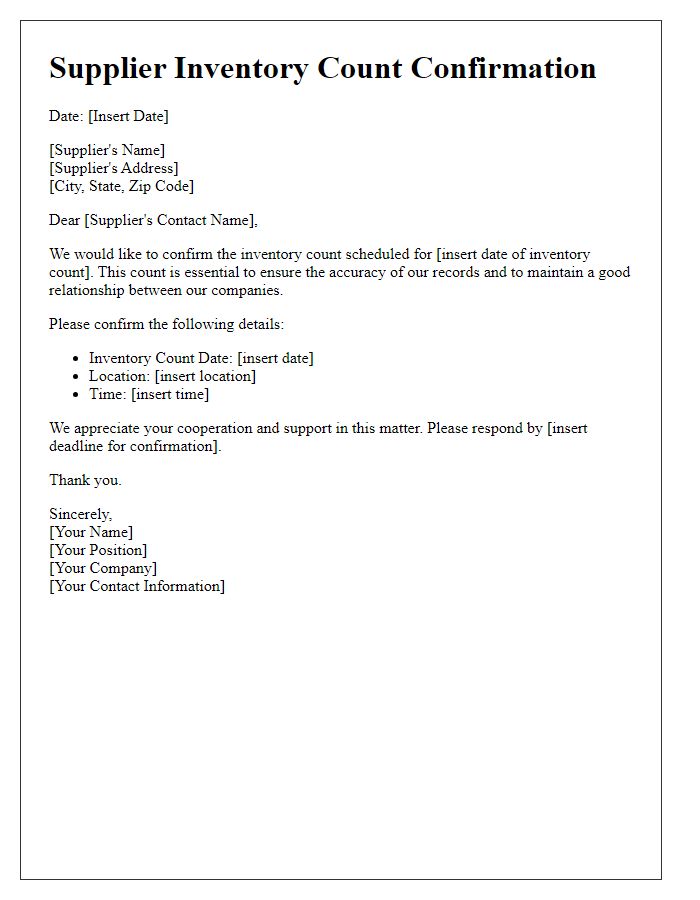

Formal greeting and recipient's name

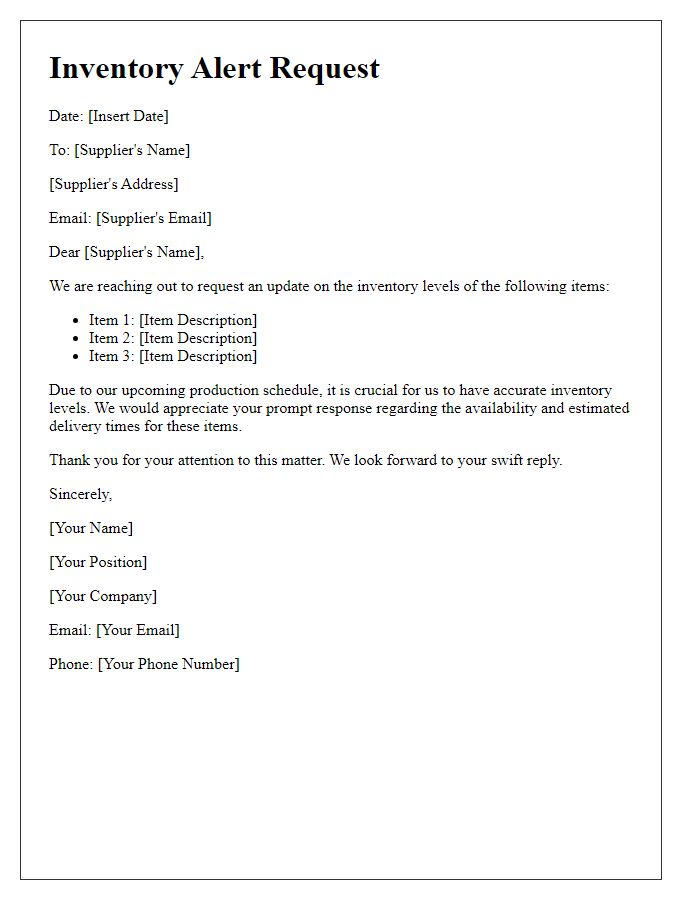

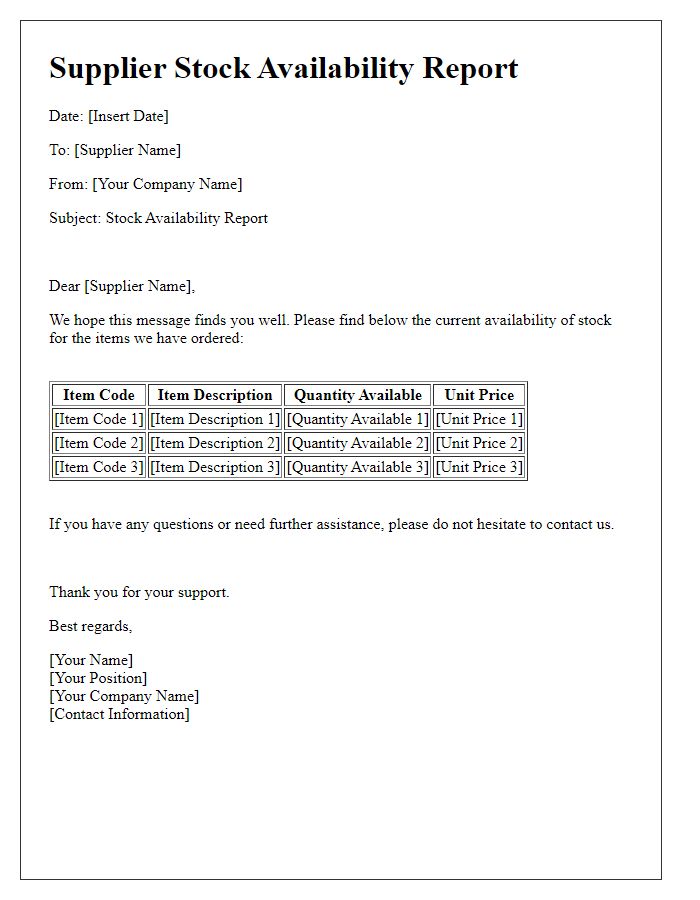

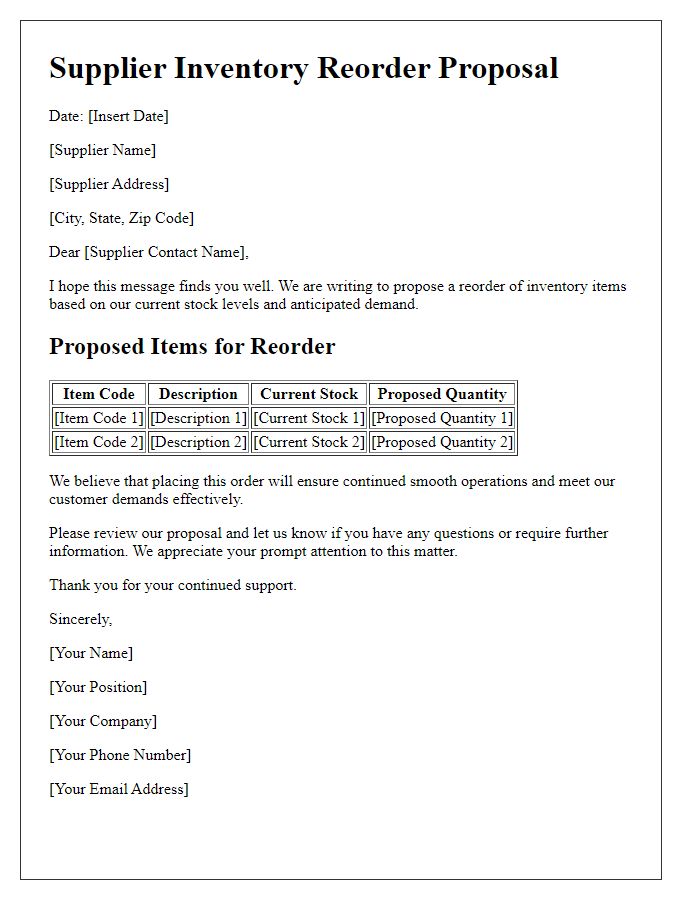

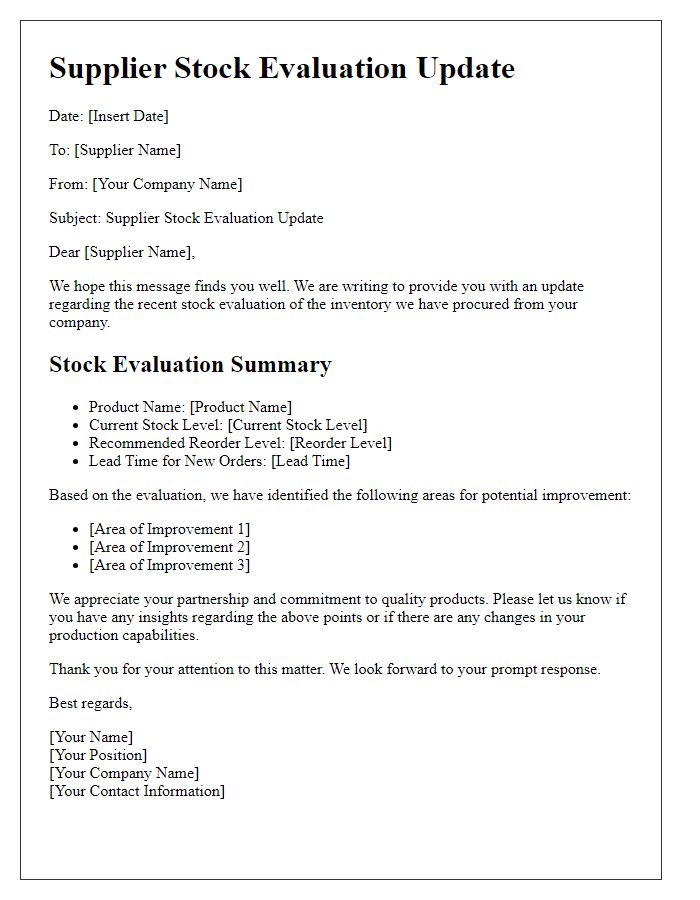

Supplier inventory levels fluctuate frequently, impacting order fulfillment and production schedules. Regular updates, such as weekly reports or monthly assessments, provide valuable insights into stock availability. Accurate inventory data, including item quantities and reorder thresholds, is crucial for maintaining operational efficiency. Maintaining communication with suppliers, especially during peak seasons, ensures timely replenishment of critical materials. Effective inventory management reduces the risk of stockouts and enhances overall supply chain performance.

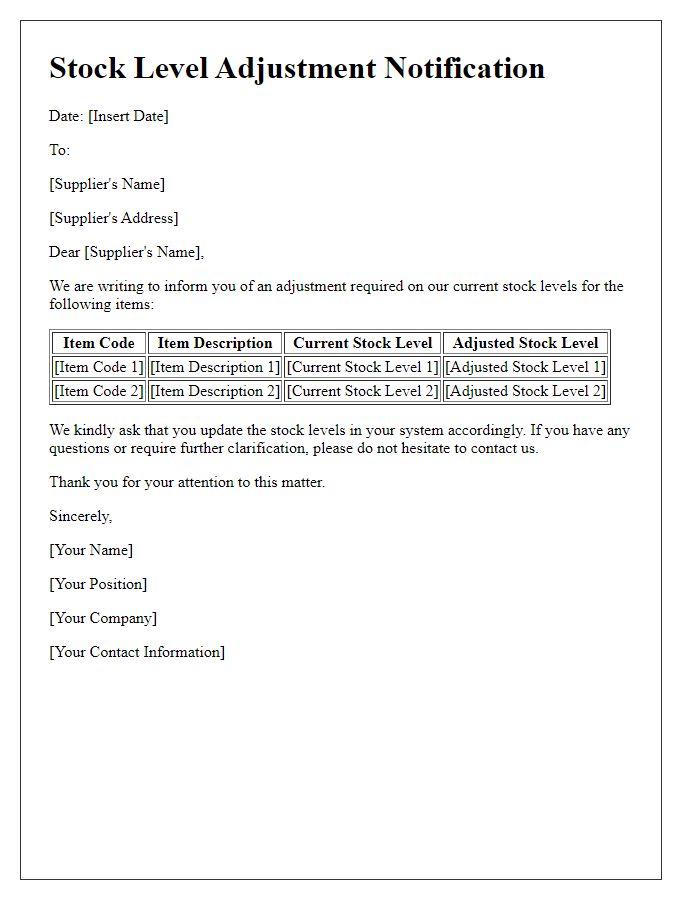

Clear subject line indicating inventory update

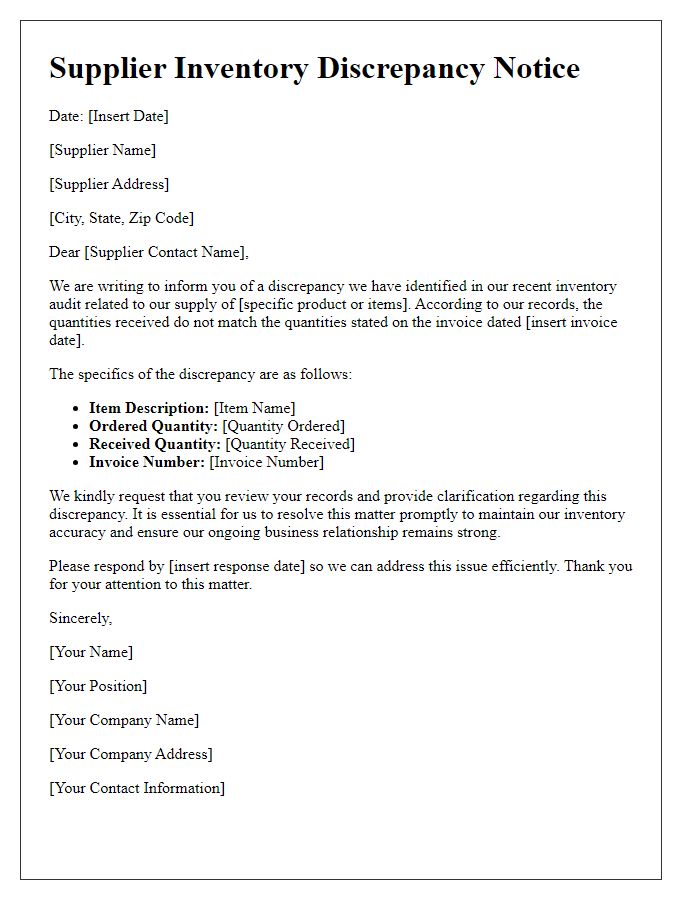

Inadequate inventory levels can disrupt supply chain efficiency in businesses. Regular updates from suppliers regarding stock quantities can prevent shortages and overstock situations. Key data points such as SKU numbers, reorder points, and lead times play a crucial role in inventory management. For instance, a sudden increase in demand for a specific product, such as a smartphone case during holidays, requires timely communication from suppliers to ensure adequate stock availability. Efficient inventory tracking systems, like Just-in-Time (JIT), can minimize carrying costs while maximizing product flow, streamlining operations in various industries including retail and manufacturing.

Detailed current inventory levels and status

Current inventory levels reveal critical data for effective supply chain management. For example, the warehouse located in Houston, Texas, holds 5,000 units of Product A, while the Chicago distribution center maintains a stock of 3,200 units. Inventory turnover rates fall within the acceptable range of 30 days, indicating a healthy flow of goods. However, Product B experiences a shortfall, with only 500 units available against a demand forecast of 1,500 units for the next month. Additionally, items such as raw materials, including steel and plastic, face fluctuating supply levels due to recent global shipping disruptions from Southeast Asia, impacting production timelines. Implementing a safety stock strategy is advisable to mitigate risks associated with stockouts. Regular audits and updates can optimize replenishment strategies moving forward.

Specific items and quantities affected

Suppliers often face fluctuations in inventory levels due to various factors impacting the supply chain. For instance, critical items such as the 22-inch LED monitors (Model XZ-123) may drop to a stock of only 50 units, while essential components like Bluetooth modules (Model MT-456) could see a decrease to 300 units. Additionally, raw materials such as high-grade aluminum sheets might be limited to 75 tons, impacting production timelines. Recent events, including port delays due to adverse weather conditions or transportation disruptions from labor strikes, contribute significantly to these variances. Regular reviews of these inventory levels are crucial for maintaining optimal supply chain operations and ensuring the availability of necessary components for uninterrupted production.

Request for confirmation or further instructions

Supplier inventory levels need to be regularly monitored to ensure timely fulfillment of orders and avoid stock shortages. Inventory reports typically detail quantities of items in stock, reorder levels, and lead times. Regular updates can indicate trends in demand, aiding in better planning. Accurate inventory management can significantly impact supply chain efficiency, reducing delays and enhancing customer satisfaction. High-demand periods, such as the holiday season or special sales events, necessitate proactive communication regarding stock levels. Confirmation from suppliers on current inventory status can ensure alignment with procurement strategies.

Comments