In today's competitive marketplace, finding ways to reduce costs while maintaining quality is more important than ever for businesses. One effective strategy is to engage in vendor cost optimization, which can lead to improved profit margins and enhanced supplier relationships. By evaluating current vendor agreements and exploring alternative options, companies can identify substantial savings opportunities without sacrificing service. Curious to learn more about how to implement these strategies effectively? Keep reading for valuable insights and practical tips!

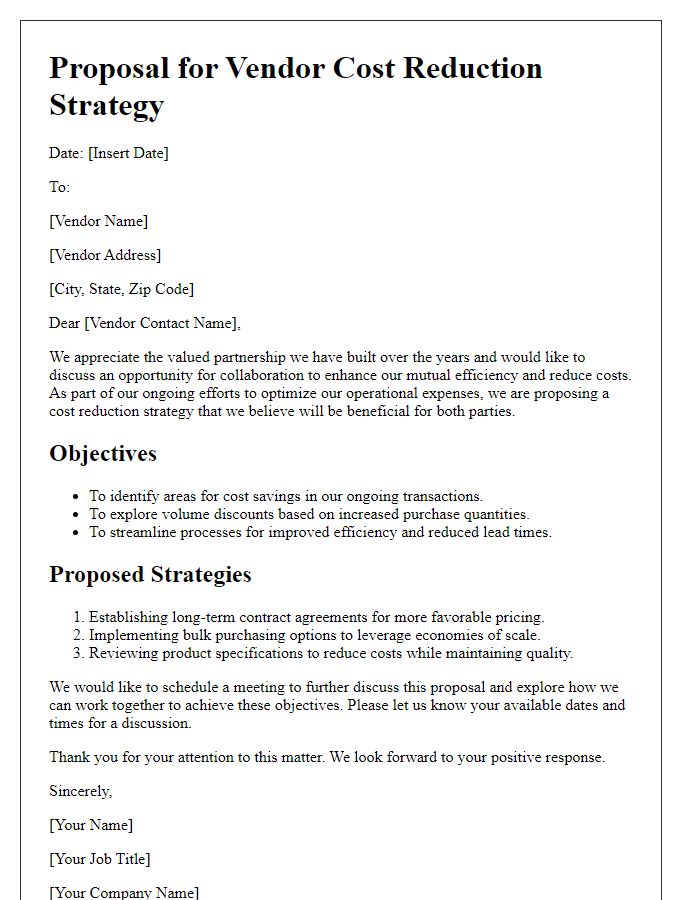

Clear objective statement

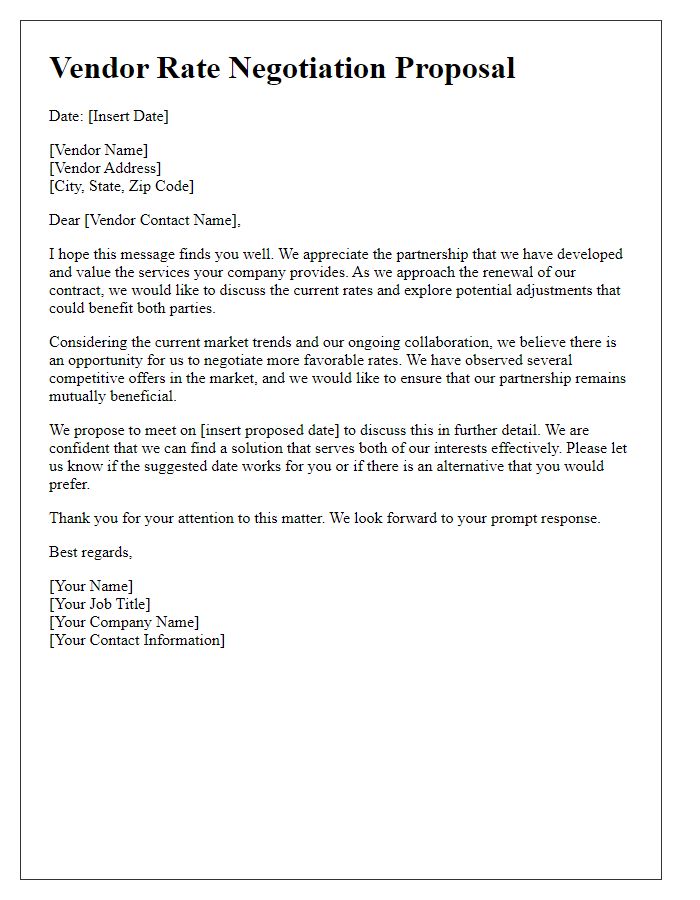

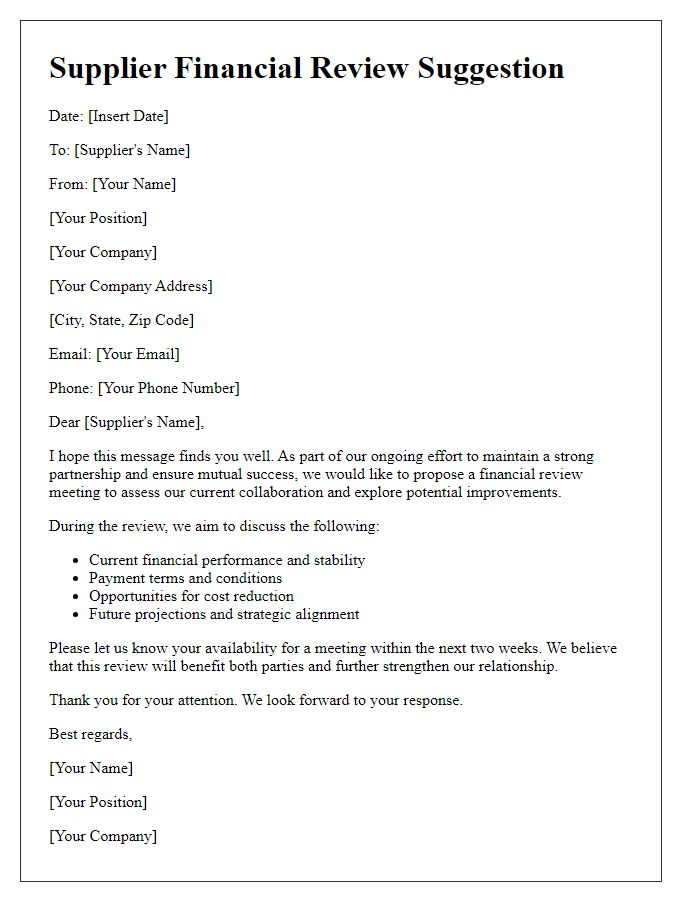

A vendor cost optimization proposal aims to reduce procurement expenses while maintaining quality standards and strengthening supplier relationships. By analyzing the existing vendor agreements, identifying cost-saving opportunities, and implementing strategic negotiation tactics, organizations can achieve a more competitive pricing model. Monthly spend reports reveal that companies can realize savings of up to 20% in operational costs. Furthermore, leveraging emerging technologies like artificial intelligence for supplier performance analytics can lead to more informed decision-making and enhanced vendor collaboration. Establishing clear objectives, setting benchmarks, and monitoring key performance indicators will ensure that the optimization efforts align with overall business goals, fostering long-term financial sustainability.

Specific cost analysis

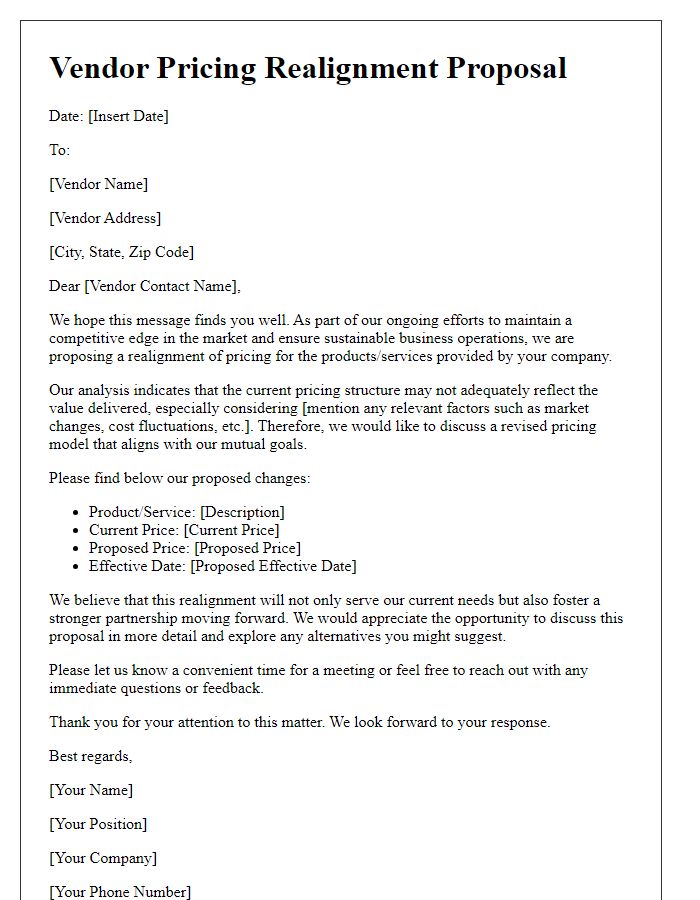

Vendor cost optimization proposals often include specific cost analyses that highlight areas for potential savings. A detailed breakdown of expenditures associated with different vendors, including product prices, service fees, shipping costs, and payment terms, can aid in identifying inefficiencies. For instance, analyzing the average monthly expenditure on supplies from Vendor A versus Vendor B may reveal that switching to Vendor B could result in a 15% reduction in costs due to lower unit prices. Additionally, evaluating bulk purchasing options or negotiating long-term contracts could yield further discounts and reduce overall expenses. Factors such as lead times, quality of materials, and customer service ratings associated with each vendor need consideration as they can affect overall project timelines and satisfaction levels. Implementing these analyses can facilitate informed decision-making that drives cost efficiency and enhances operational profitability.

Value proposition

A vendor cost optimization proposal aims to enhance cost efficiency while maintaining quality excellence in supply chain management. Identifying critical areas for cost reduction, such as bulk purchasing discounts, transportation optimization, and streamlined processes, can significantly impact overall expenses. Analysis of historical data (like 12 months' worth of procurement trends) reveals potential savings ranging from 10% to 30% per contract. Implementing innovative technologies, such as AI-driven procurement tools, can further analyze vendor performance, ensuring transparency and accountability in vendor selection processes. Collaboration with strategic partners located in key manufacturing hubs, like Southeast Asia or Eastern Europe, may yield economies of scale that drive down costs while upholding product quality and delivery timelines.

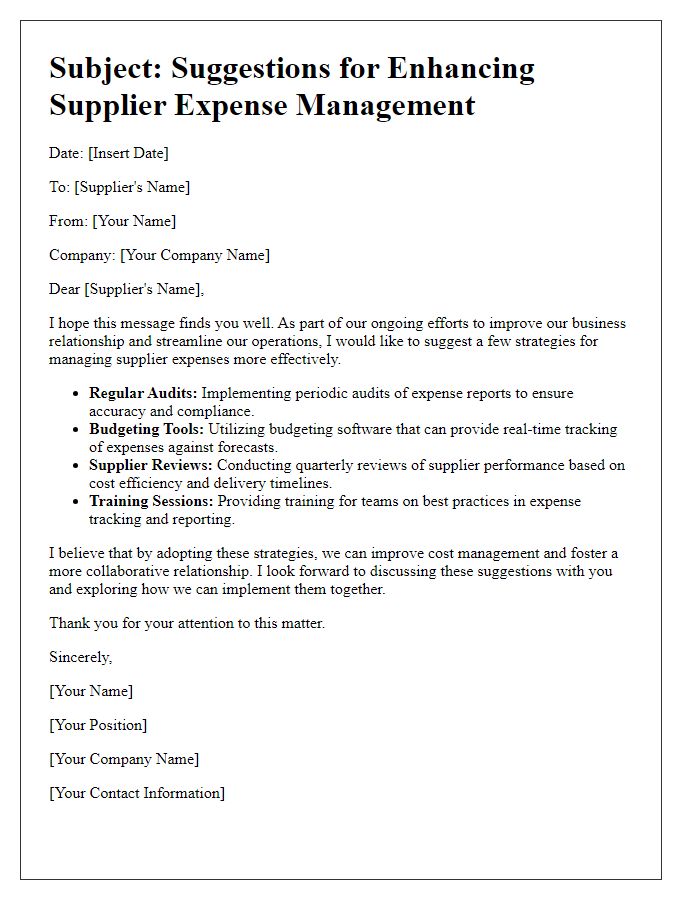

Strategic partnership benefits

Strategic partnerships can significantly enhance cost optimization for vendors by leveraging combined resources and capabilities. Collaborative efforts can lead to economies of scale, enabling reduced operational costs and improved procurement efficiency. Sharing technology and expertise can create innovative solutions, driving down expenses associated with research and development. In addition, streamlined logistics and distribution networks can minimize transportation costs (often accounting for over 30% of total supply chain expenditures). Furthermore, data-driven insights gathered from joint market analysis can refine pricing strategies, ensuring competitive advantage. Overall, fostering strategic partnerships not only cultivates a more resilient supply chain but also maximizes profitability for all parties involved.

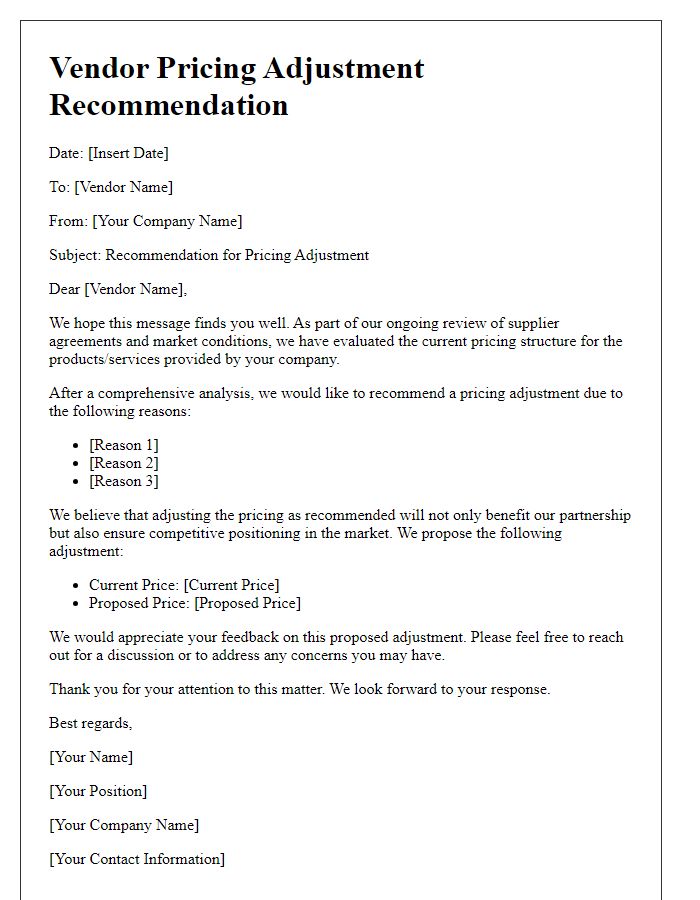

Call to action

A vendor cost optimization proposal aims to streamline expenses while enhancing service quality and product value. Key figures can illustrate potential savings, such as a projected 15% reduction in costs over the next fiscal year. Targeting strategic suppliers with a strong history of collaboration can further establish effective negotiation approaches. This initiative could involve specific sectors such as logistics, raw materials procurement, or technology services, emphasizing reliable partnerships over the long term. Timely execution of the proposal is crucial, especially considering current economic fluctuations, which require agile responses to maintain competitiveness. Engaging stakeholders through transparent communication fosters collaboration, while regular reviews ensure the optimization process adapts to changing market conditions.

Comments