Are you looking to strengthen your relationship with suppliers while optimizing costs? In today's competitive market, it's essential to find ways to reduce expenses without compromising quality. Crafting a well-structured letter to propose cost reductions can pave the way for fruitful negotiations. Join us as we explore effective strategies and templates that will help you navigate this process with ease; read more to discover how to make your proposal stand out!

Clear objective statement

A cost reduction proposal aims to enhance profitability through strategic pricing negotiations. Suppliers, such as raw material producers or logistical partners, are key stakeholders in this process. The objective is to lower procurement costs by at least 10%, which aligns with industry standards for efficiency improvements. Target reductions will focus on specific categories, including bulk purchasing discounts and reduced shipping fees. The anticipated outcome is improved budget allocation towards innovation and growth initiatives within the organization, leading to a stronger market position in competitive sectors.

Detailed cost analysis

A detailed cost analysis presents an opportunity for suppliers to evaluate and reduce expenses across various operational categories. In manufacturing settings, raw material costs (such as steel in automotive production) can constitute up to 60% of total expenditures. Labor costs (including wages and benefits) often account for an additional 25% of overall expenses. Transportation logistics, particularly for international shipping (which can involve tariffs and customs fees), can further drive up costs by as much as 15% depending on the supply chain complexity. Implementing strategies such as bulk purchasing (which can lower material costs through economies of scale), optimizing workforce management (to enhance productivity and reduce labor-related expenses), and streamlining logistics (by selecting more efficient shipping routes and methods) can significantly contribute to cost reductions. By analyzing these key categories, suppliers can identify areas for improvement, leading to sustainable financial benefits.

Strategic collaboration opportunities

A strategic collaboration effort focusing on cost reduction can significantly benefit both suppliers and manufacturers in various industries. Such initiatives may involve joint procurement strategies, where suppliers can pool resources to negotiate better pricing from raw material vendors, resulting in lower overall costs. Innovative manufacturing techniques, like lean production methods employed by companies such as Toyota, can enhance efficiency and reduce waste, thus positively impacting costs. Implementing technology like automation in fabrication processes can further streamline production and decrease labor expenses. Establishing transparent communication channels allows for better forecasting and inventory management, subsequently reducing holding costs. Engaging in sustainable practices can also avert potential regulatory costs while resonating with environmentally-conscious consumers. Specific examples from successful collaborations, such as Walmart's commitment to cost-saving partnerships, can serve as a model for identifying potential areas for shared investment and mutual growth. Through these collaborative strategies, suppliers and manufacturers can achieve a win-win scenario, ensuring a robust and resilient supply chain.

Benefits and savings overview

Supplier cost reduction proposals can significantly enhance profitability and operational efficiency. By renegotiating contracts with suppliers such as raw material providers or logistics companies, businesses can potentially save up to 15% on procurement costs. Implementing bulk purchasing strategies often yields additional discounts and reduces per-unit expenses. Streamlining processes through technology, such as inventory management systems, can lead to reduced waste and lower holding costs by as much as 30%. Engaging in collaborative initiatives with suppliers can foster innovation and drive down production costs through shared resources and knowledge. Transformative partnerships not only create immediate financial benefits but also bolster long-term sustainability in supply chains.

Contact information for follow-up

Implementing effective cost reduction strategies can significantly enhance supplier partnerships. A comprehensive review of pricing structures, material sourcing, and logistical efficiencies can reveal opportunities for savings. For instance, negotiating bulk purchasing agreements (typically exceeding 1,000 units) can lead to discounts. Additionally, exploring alternative suppliers within regions like Southeast Asia, known for competitive pricing, may provide further cost-reduction avenues. Establishing clear communication channels will facilitate ongoing discussions and adjustments to pricing frameworks, ensuring mutual benefits for both suppliers and clients. Regular performance assessments can identify areas for additional reductions, optimizing overall procurement costs.

Letter Template For Supplier Cost Reduction Proposal Samples

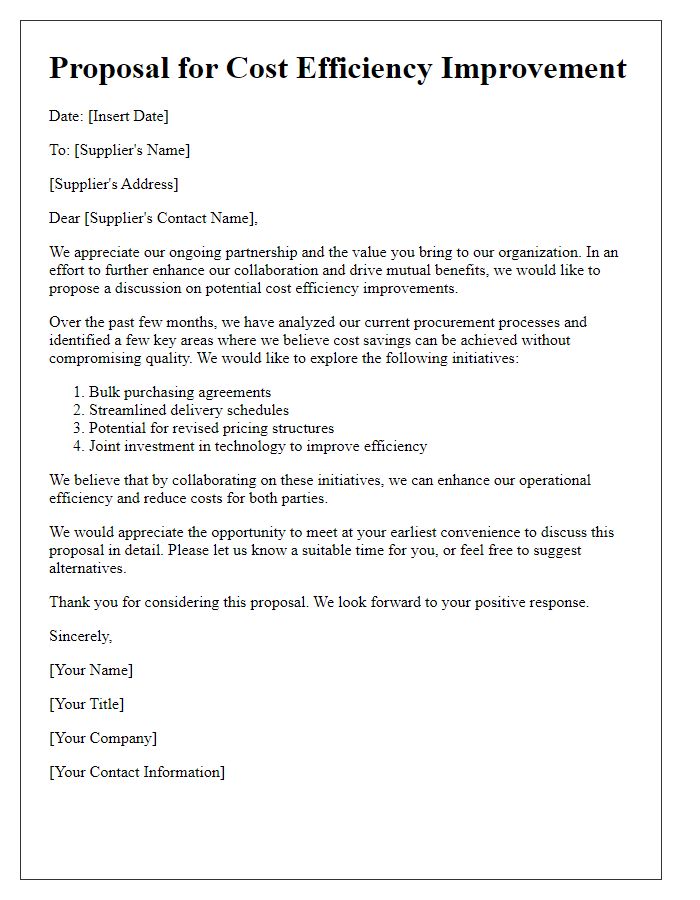

Letter template of Proposal for Cost Efficiency Improvement with Supplier

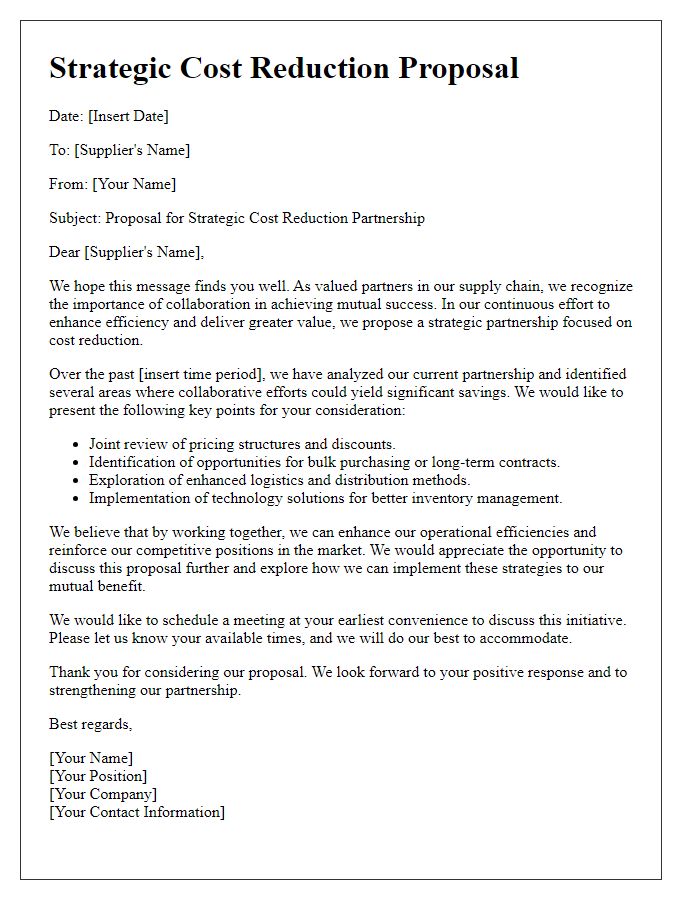

Letter template of Strategic Cost Reduction Proposal for Supplier Partnership

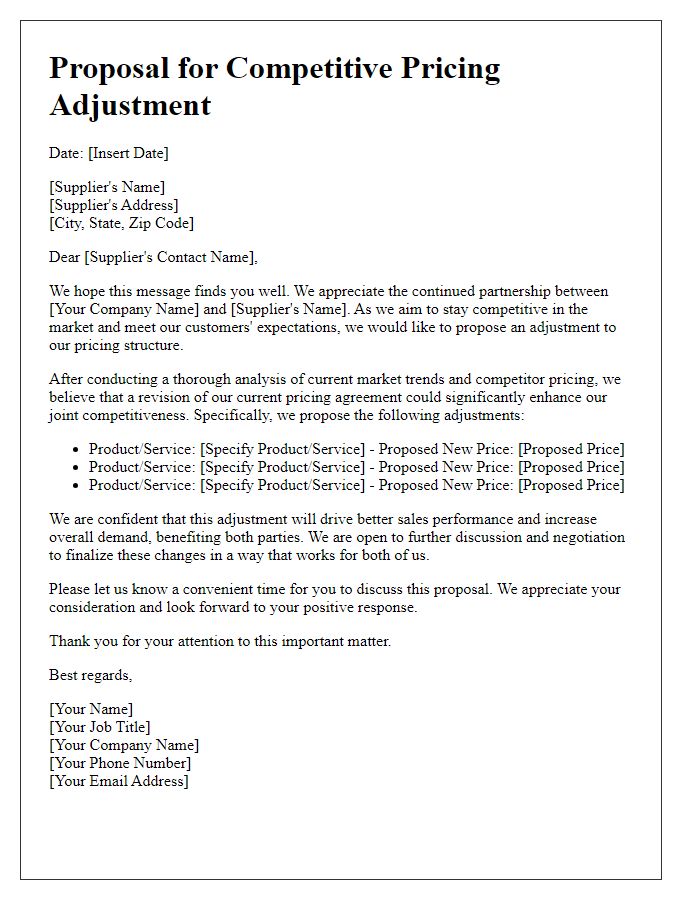

Letter template of Proposal for Competitive Pricing Adjustment from Supplier

Comments