Hey there! We're excited to share some insightful updates about our reseller supply chain that can help you stay ahead in this dynamic market. Understanding the shifts and improvements we're implementing is crucial for fostering a successful partnership and optimizing your inventory strategies. From enhanced logistics to better communication channels, these changes are designed with your success in mind. Read on to discover how these updates can benefit your business and keep you competitive!

Clarity and Brevity

A reseller supply chain update is crucial for ensuring effective communication regarding product availability and order fulfillment. In today's fast-paced environment, transparency in stock levels (including backorders and lead times) is essential for maintaining trust. Updates should highlight key metrics, such as the average delivery time ( currently 5-7 business days), inventory turnover rates (ideally 2-4 times per month), and any disruptions caused by external factors like transportation delays or supplier issues. Clarity around these points allows resellers to manage customer expectations effectively and make informed decisions regarding inventory management. Involving a consistent schedule for updates (weekly or bi-weekly) enhances reliability and keeps all stakeholders informed.

Customized Greetings

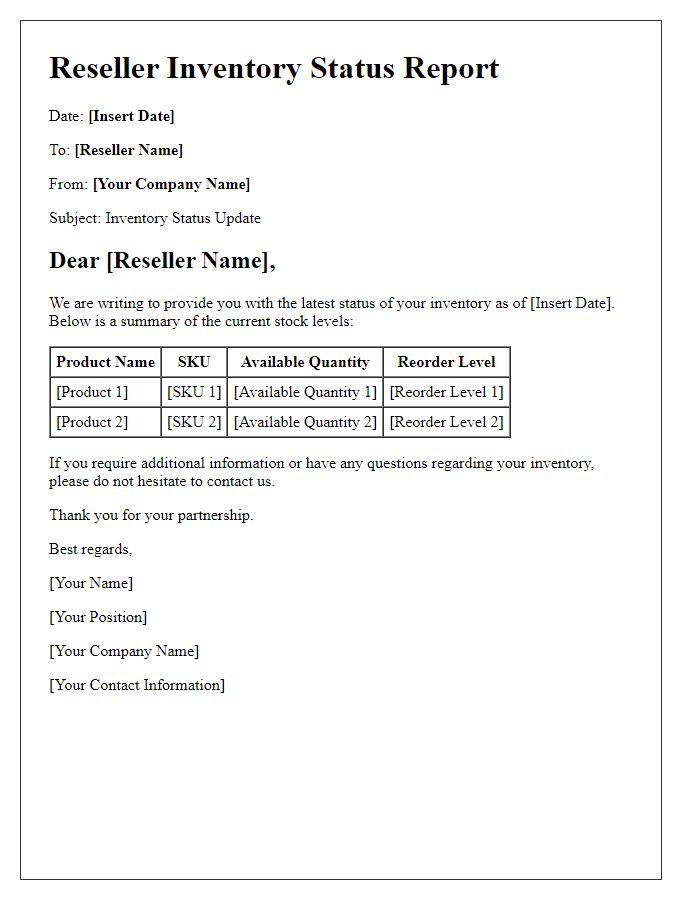

Supply chain updates are critical for resellers operating in fast-paced markets like technology and consumer goods. Recent shifts in logistics have impacted delivery timelines across various regions, including North America and Europe. The implementation of new software systems enhances inventory management, allowing for real-time tracking on approximately 85% of shipments. Partnerships with key carriers, such as FedEx and UPS, aim to reduce transit times by 20%, addressing urgent customer demands effectively. Additionally, product sourcing has expanded to include eco-friendly options, catering to the growing demand for sustainable goods among consumers. Keeping clients informed through regular communication enhances trust and ensures alignment with evolving market conditions.

Key Product Updates

Key product updates in the supply chain for resellers can significantly impact inventory management and sales performance. The introduction of new models, such as the iPhone 15 series, announced in September 2023, requires timely adjustments in stock levels. Notifications from manufacturers highlight changes in lead times, particularly for components like chipsets from Taiwan Semiconductor Manufacturing Company (TSMC), which can range from 8 to 12 weeks. Additionally, shipping timelines from key ports, such as Long Beach, have fluctuated due to ongoing supply chain disruptions, impacting delivery schedules. Resellers are advised to monitor these updates closely to optimize their replenishment strategies and ensure availability for end customers.

Supply Chain Adjustments

Supply chain adjustments significantly impact the logistics and distribution of goods, especially in the reseller market. Recent disruptions, stemming from global events such as the COVID-19 pandemic, have led to delays in shipments across various sectors. For instance, shipping times for electronics from manufacturers in Asia have increased by 30% due to port congestion. Additionally, rising costs of raw materials, including metals and plastics, have seen price increases of up to 20%, thereby affecting the overall pricing strategy. Regions like North America and Europe are facing challenges in sourcing components, resulting in a ripple effect on delivery timelines and inventory levels. Companies must adapt quickly to these fluctuations to maintain customer satisfaction and optimize their operations.

Call to Action

Reseller networks require effective communication regarding supply chain updates, especially during critical periods of demand fluctuation. Supply chain disruptions can arise from various factors, including transportation issues, geopolitical events, or manufacturing delays in regions such as Southeast Asia. It is essential for resellers to monitor inventory levels meticulously and respond swiftly to changes. Establishing clear protocols for order placement is crucial, ensuring timely restocking of high-demand products like electronics or automotive parts. Regular updates should highlight key performance indicators such as lead times, stock availability, and market demand trends. Additionally, fostering collaboration between suppliers and resellers can enhance responsiveness to changing consumer needs, fostering greater efficiency within the supply chain framework.

Comments