In today's fast-paced pharmaceutical landscape, ensuring business continuity is more critical than ever. A well-crafted continuity plan not only safeguards operations but also reinforces trust among partners and clients. By anticipating potential disruptions and outlining clear strategies, companies can maintain their essential functions regardless of unexpected challenges. Ready to delve deeper into how to create an effective business continuity plan for your pharmaceutical business?

Clear Objectives and Scope

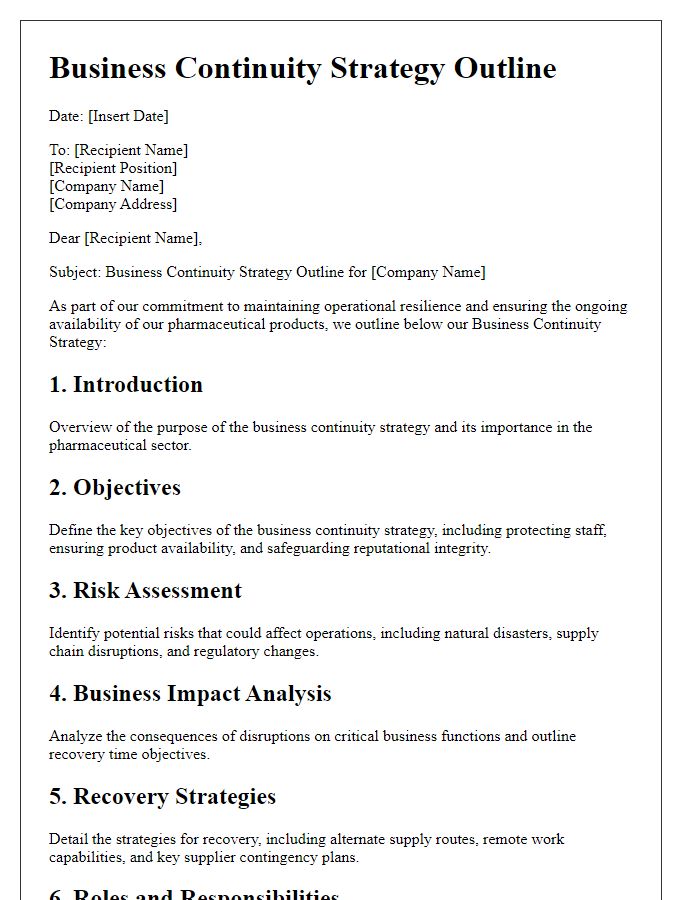

A pharmaceutical business continuity plan focuses on maintaining operational resilience amid disruptions such as supply chain interruptions or regulatory changes. Clear objectives include ensuring patient safety by minimizing drug shortages and ensuring compliance with industry regulations. The scope covers critical functions, including research and development facilities like those in Cambridge, Massachusetts, manufacturing plants like the one in Dublin, Ireland, and distribution channels to pharmacies and hospitals nationwide. Risk assessment processes identify potential threats, including natural disasters or cyberattacks, while communication strategies ensure stakeholders such as healthcare providers and regulatory bodies remain informed during a crisis. Ultimately, the plan aims to safeguard public health by enabling swift recovery and continuity of essential pharmaceutical services.

Risk Assessment and Mitigation Strategies

A well-structured business continuity plan is essential for the pharmaceutical industry, particularly in risk assessment and the implementation of effective mitigation strategies. Potential risks include supply chain disruptions due to natural disasters, such as hurricanes or earthquakes, affecting distribution centers in regions like Puerto Rico or the Gulf Coast. Regulatory challenges arising from agencies such as the FDA may delay product launches or affect compliance, necessitating proactive analysis of regulatory changes. Production facility issues, such as equipment malfunctions or contamination, can halt manufacturing processes, highlighting the importance of regular maintenance schedules and contingency plans. Additionally, cybersecurity threats pose significant risks, given the sensitive nature of clinical data and intellectual property. Therefore, an integrated approach involving risk identification, comprehensive analysis, and robust contingency measures is crucial to ensure operational resilience and uphold patient safety.

Communication Plan and Stakeholder Engagement

A well-defined communication plan is crucial for a pharmaceutical business continuity plan, particularly in crisis situations that may disrupt operations, such as supply chain interruptions or regulatory changes. The communication plan should outline clear protocols for internal communication among employees, including channels such as emails, newsletters, and intranet bulletins to ensure all staff are informed and engaged. Stakeholder engagement requires identifying key parties, such as suppliers, regulatory bodies (like the FDA in the United States), healthcare providers, and patients. Regular updates should be scheduled, such as weekly briefings or quarterly meetings, to discuss ongoing issues and resolutions. Utilizing tools like virtual conferences or collaborative platforms can enhance stakeholder interaction and feedback. Additionally, crisis communication protocols must be established to address unexpected incidents swiftly, ensuring that all parties receive timely and accurate information to minimize confusion and maintain trust.

Resource Allocation and Responsibility Assignments

In the pharmaceutical industry, effective resource allocation is crucial for ensuring continuous operations during disruptions such as pandemics or supply chain interruptions. Human resources (approximately 25% of a company's workforce) must be clearly assigned specific roles, including crisis management leaders and operational continuity teams. Financial resources should be allocated to maintain essential functions, with a budget of at least 15% set aside for unexpected obstacles. Moreover, critical assets, such as laboratories and manufacturing facilities (located in regions like North Carolina or New Jersey), require strategic protection and prioritization to minimize downtime. Supply chain partners, including raw material suppliers and distribution networks, must be identified and engaged to maintain a seamless flow of essential drugs and vaccines. Regular training and simulations can prepare staff for unforeseen events, ensuring roles, responsibilities, and resource needs are well understood and actionable.

Monitoring, Review, and Continuous Improvement

Monitoring and review processes are essential for the success of a pharmaceutical business continuity plan (BCP) that ensures compliance with industry regulations (such as FDA or EMA guidelines) and minimizes disruptions. Regular audits (conducted quarterly) assess the effectiveness of the plan, identifying potential risks in supply chain management and regulatory compliance. Performance metrics, such as recovery time objectives (RTO) and recovery point objectives (RPO), are documented to ensure timely recovery from incidents. Continuous improvement strategies are employed, utilizing feedback from risk assessments and incident responses, to enhance the resilience of operations across various sectors, including manufacturing, distribution, and clinical trials. Training programs for employees promote awareness of protocols, ensuring everyone is equipped to react effectively during emergencies, thereby safeguarding patient safety and maintaining product integrity.

Letter Template For Pharmaceutical Business Continuity Plan Samples

Letter template of pharmaceutical employee safety and communication plan

Letter template of pharmaceutical stakeholder engagement during disruptions

Comments