When it comes to ensuring a smooth process in manufacturing, a well-crafted order confirmation letter is essential. This document not only serves as a formal acknowledgment of your order but also helps prevent any potential misunderstandings down the line. Including key details such as order specifications, delivery timelines, and payment terms fosters clear communication and builds trust between parties. If you're curious about how to create an effective manufacturing order confirmation letter, read on for valuable tips and examples!

Company Information

A manufacturing order confirmation document typically includes detailed company information that ensures clarity and accountability. Essential elements include the full legal name of the manufacturing company, such as "XYZ Manufacturing Corp," displayed prominently at the top. Directly beneath, the registered address, for example, "123 Industrial Park, Suite 100, Springfield, IL 62701," provides assurance regarding the company's location. Contact information, including a dedicated phone number (e.g., "(555) 123-4567") and an official email address (e.g., "info@xyzmfg.com"), facilitates easy communication. Additionally, including the company's website (e.g., "www.xyzmfg.com") allows parties to verify credentials and explore services offered. The company's logo, prominently placed, further reinforces brand identity and professionalism in the confirmation document.

Order Details

The manufacturing order confirmation includes crucial information such as order number 12345, placing it within the context of a recent transaction on October 10, 2023. The order consists of 500 units of precision-engineered components made from high-strength aluminum alloy, destined for a facility located in Detroit, Michigan. Each unit must meet stringent quality standards specified by ISO 9001:2015 certification, ensuring reliability in high-load applications. Additionally, the expected delivery date is set for November 15, 2023, aligning with the client's production schedule to avoid delays in assembly. A detailed breakdown of costs, including materials and labor, totals $25,000, providing transparency and aiding budget planning for the buying company.

Payment Terms

Manufacturing order confirmations often detail key aspects such as payment terms, specifying conditions related to transaction settlement. Standard practices include stipulations like 30% advance payment, with the remaining 70% due upon order completion. In some cases, net 30 days after invoice issuance is a common term, requiring clients to settle accounts within a month. Alternative methods may involve payment via secure bank transfer, credit card processing, or utilizing letters of credit, depending on the manufacturing company and client agreement. Furthermore, penalties may apply for late payments, affecting future orders or service continuity. Understanding and agreeing upon these terms is crucial for maintaining a healthy business relationship between manufacturers and clients.

Delivery Schedule

The manufacturing order confirmation outlines the delivery schedule, detailing crucial timelines for production and shipment. Scheduled production dates, such as January 15, 2024, highlight the commencement of manufacturing processes in facilities like the Main Assembly Plant in Ohio, which is equipped to handle large-scale operations. Expected shipping dates, estimated by February 5, 2024, will facilitate timely delivery across the supply chain, ensuring compliance with customer requirements. Tracking information will be provided via a logistics partner, ensuring accountability during transit to client locations, such as warehouses in Los Angeles, California. Components like packaging specifications will adhere to industry standards, promoting protection and minimizing damage during shipment.

Contact Information

Manufacturing order confirmation involves critical information detailing specific requirements for production. The supplier's contact information includes essential details: company name, physical address for shipping, telephone number for inquiries, and email address for electronic communication. The order number, a unique identifier assigned to track the request, must be clearly noted. Additionally, product specifications such as dimensions, materials, quantities, and delivery timelines play a vital role in ensuring accuracy. Payment terms, including agreed methods and schedules, should also be stated to avoid any misunderstandings. Completing this information accurately helps maintain smooth operations in the manufacturing process.

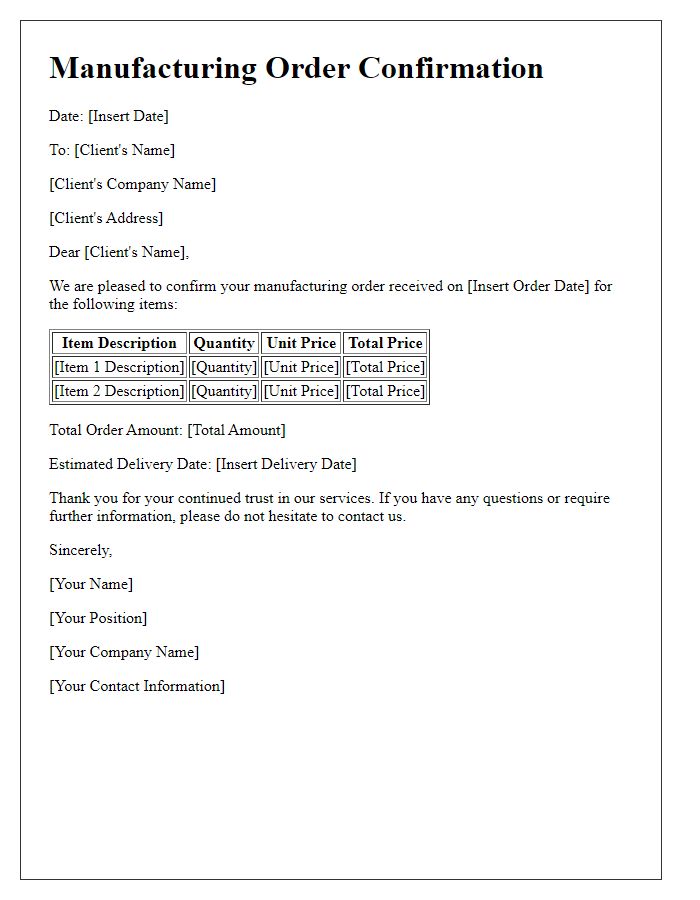

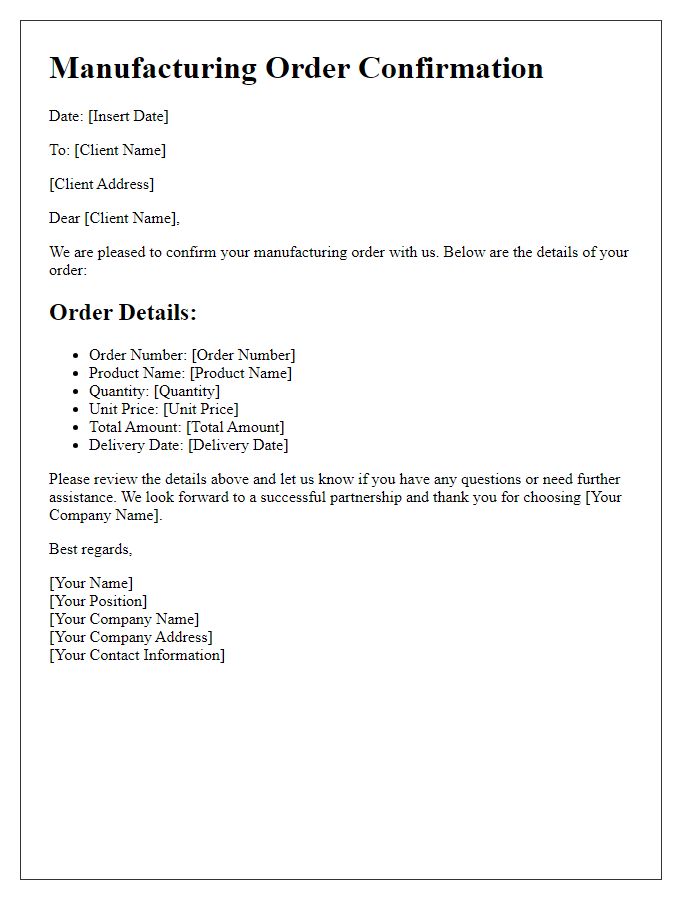

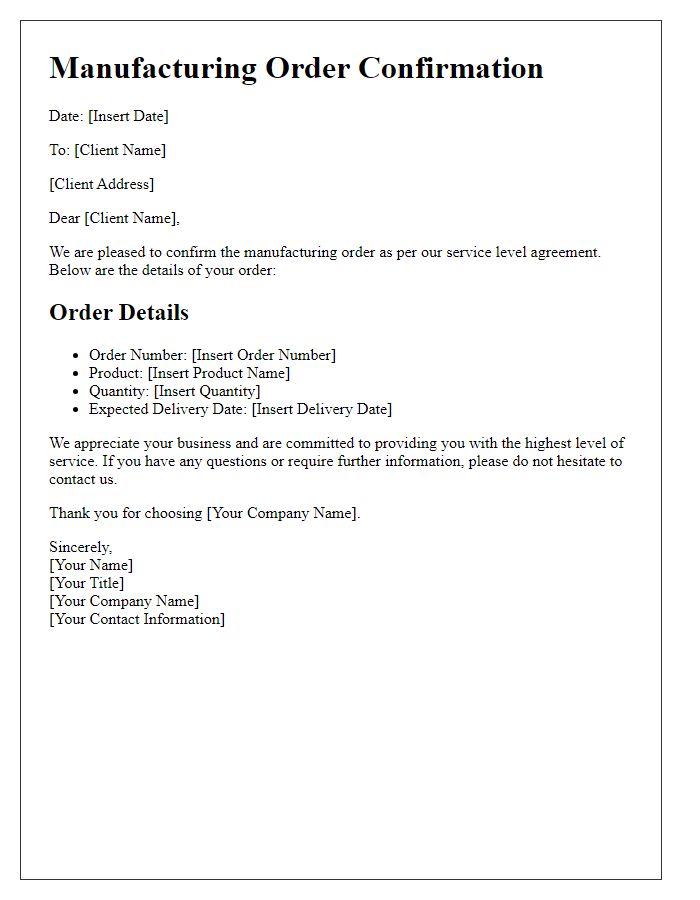

Letter Template For Manufacturing Order Confirmation Samples

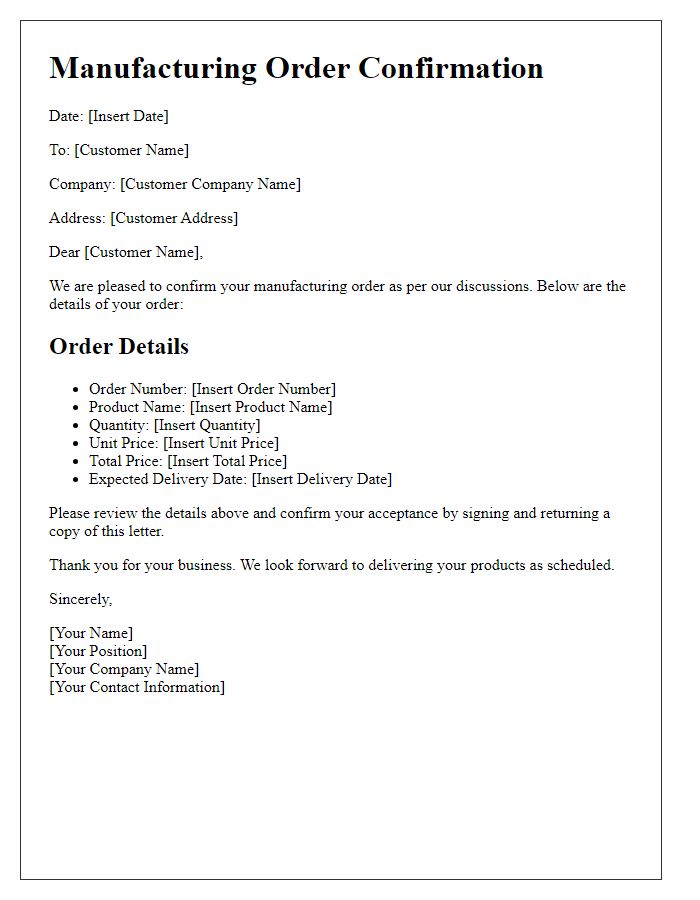

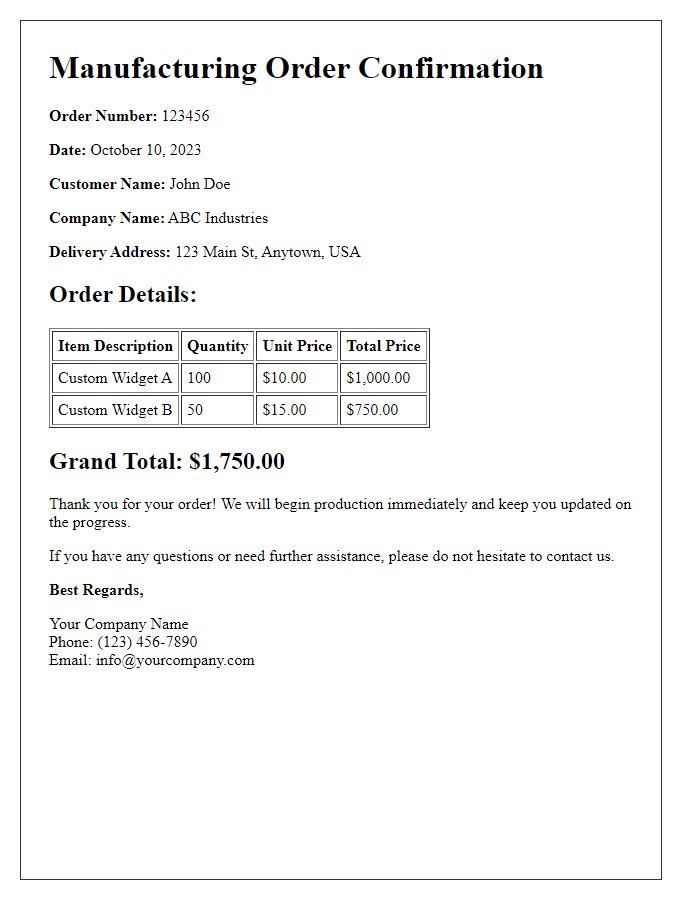

Letter template of manufacturing order confirmation for bulk production.

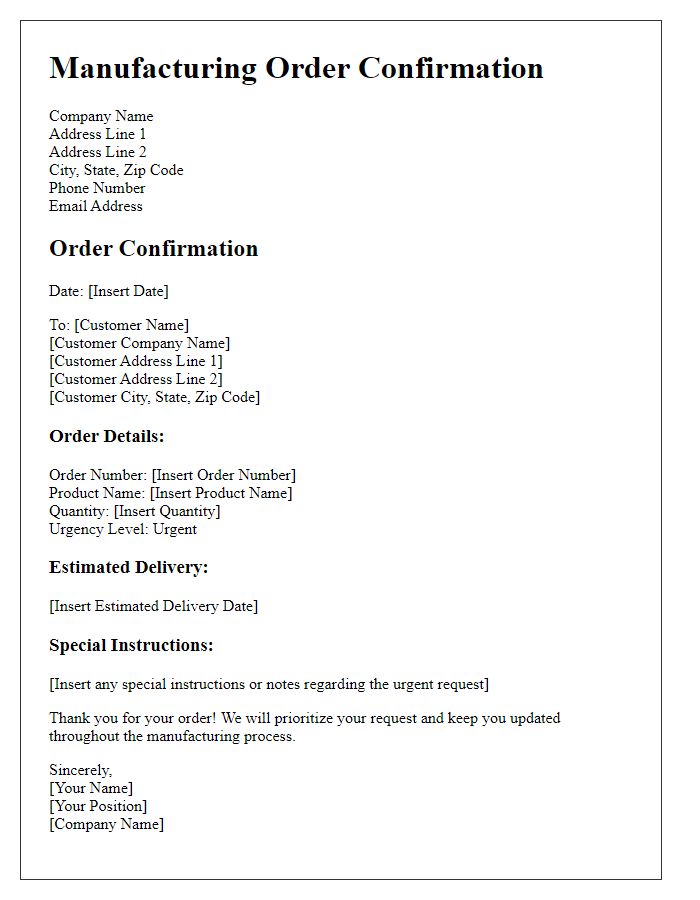

Letter template of manufacturing order confirmation for urgent requests.

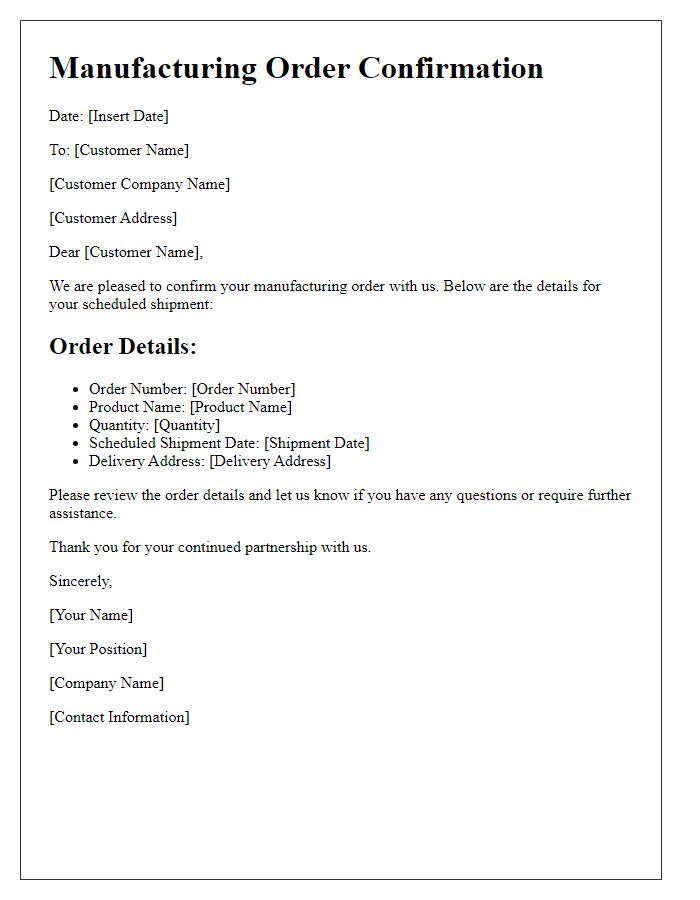

Letter template of manufacturing order confirmation for scheduled shipments.

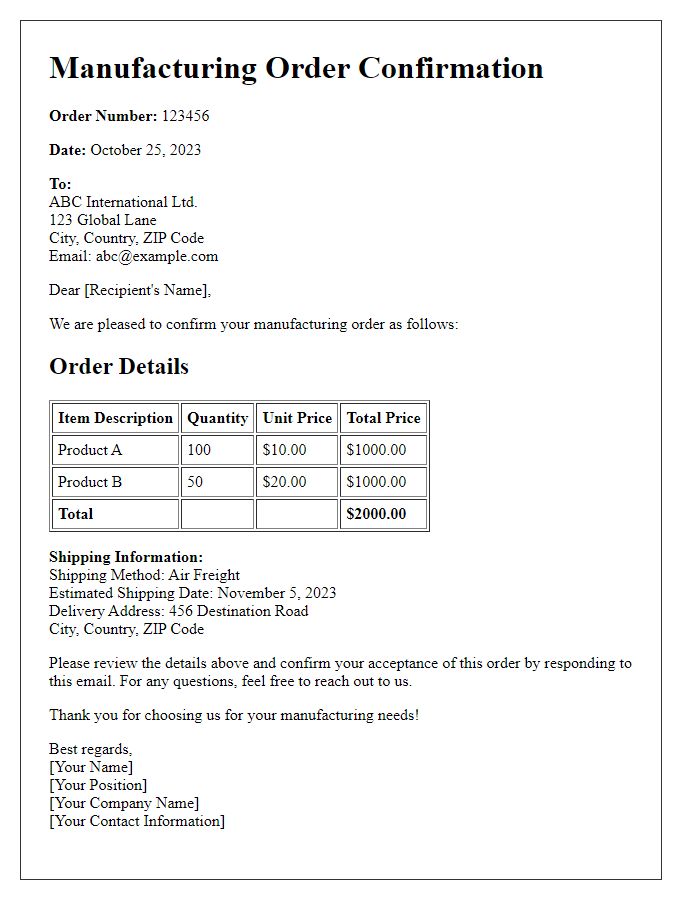

Letter template of manufacturing order confirmation for international shipping.

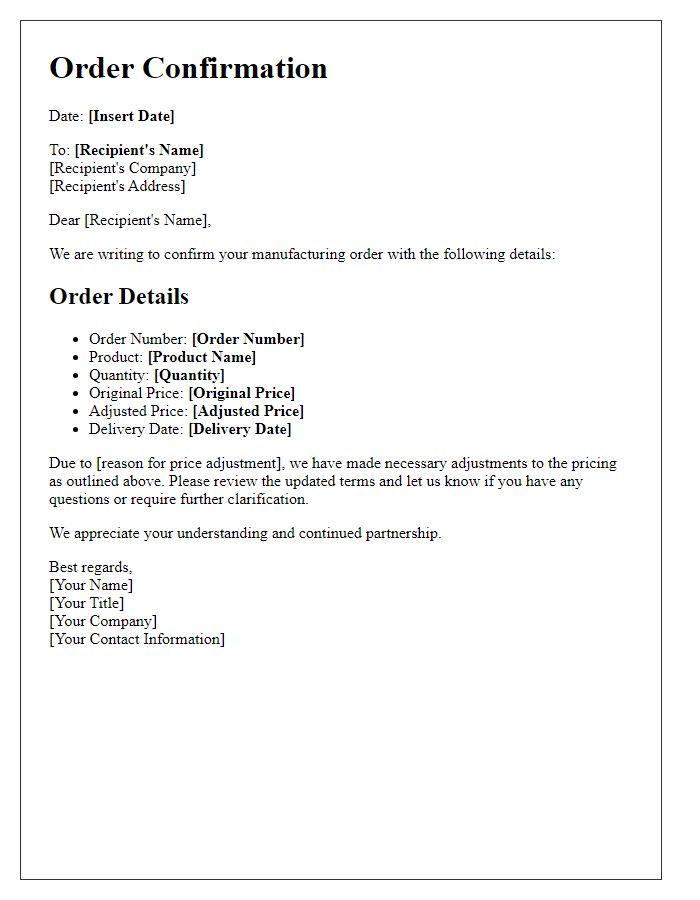

Letter template of manufacturing order confirmation for pricing adjustments.

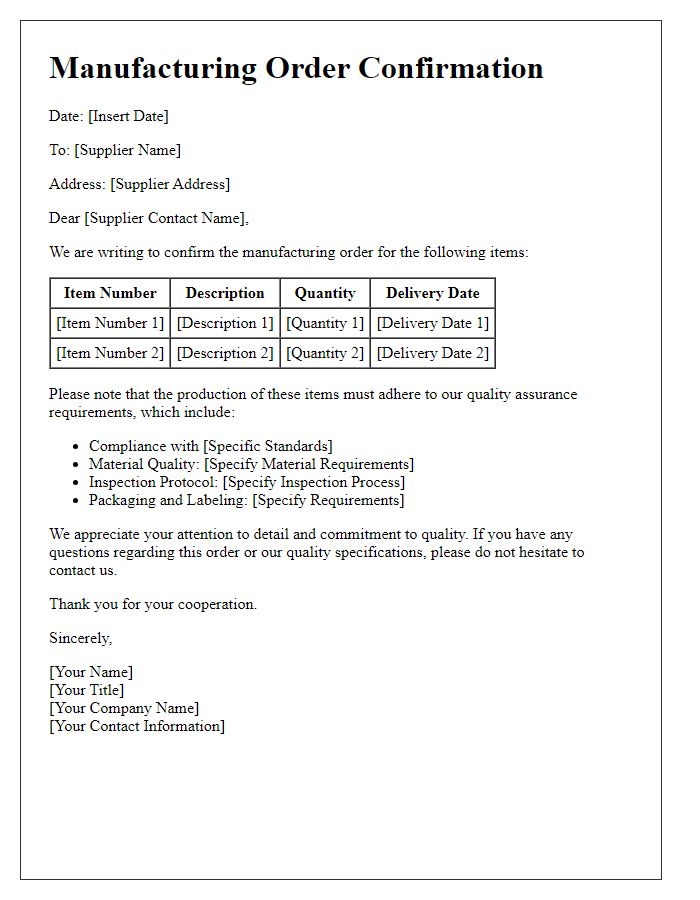

Letter template of manufacturing order confirmation for quality assurance requirements.

Comments