In today's competitive market, ensuring the quality of your products is more crucial than ever. A well-structured product quality assessment authorization letter not only streamlines the evaluation process but also establishes trust between manufacturers and stakeholders. By setting clear expectations and guidelines, this letter acts as a foundation for effective communication and collaboration. Ready to take your quality assurance to the next level? Let's dive deeper into crafting the perfect letter!

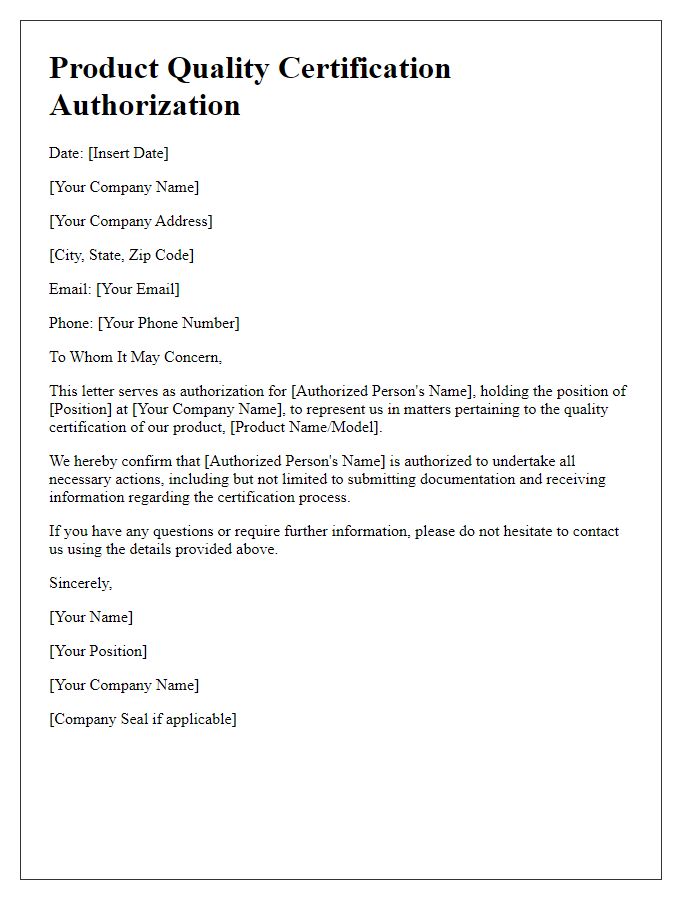

Company Details

A product quality assessment authorization is essential for organizations like XYZ Electronics, established in 2010, renowned for innovative home appliances. This authorization facilitates the evaluation of product efficacy, safety, and compliance with industry standards such as ISO 9001. Quality assessment personnel from accredited bodies like SGS (Societe Generale de Surveillance) or Intertek perform rigorous testing protocols in laboratory settings to ensure defect rates remain below 2%, vital for maintaining the brand's reputation. Detailed documentation, including specifications, user manuals, and warranty information, accompanies the assessment process, providing stakeholders with comprehensive insights into product durability and reliability. This proactive approach to quality assurance fosters consumer trust and promotes long-term customer satisfaction, crucial in today's competitive market landscape.

Product Specifications

Product specifications play a crucial role in the quality assessment process for various items, including electronics such as smartphones, appliances, and automotive parts. Detailed specifications often include dimensions (height, width, depth in millimeters), materials (like aluminum, glass, or polymer), and performance metrics (e.g., battery life of 12 hours or processing speed of 2.5 GHz). These specifications directly influence the manufacturing process, ensuring that quality standards are met according to industry regulations such as ISO 9001. Additionally, compliance with safety standards (like UL certification for electrical devices) guarantees user safety during operation. A thorough evaluation of product specifications ensures that all stakeholder expectations are addressed, minimizing risks associated with defective products and enhancing customer satisfaction.

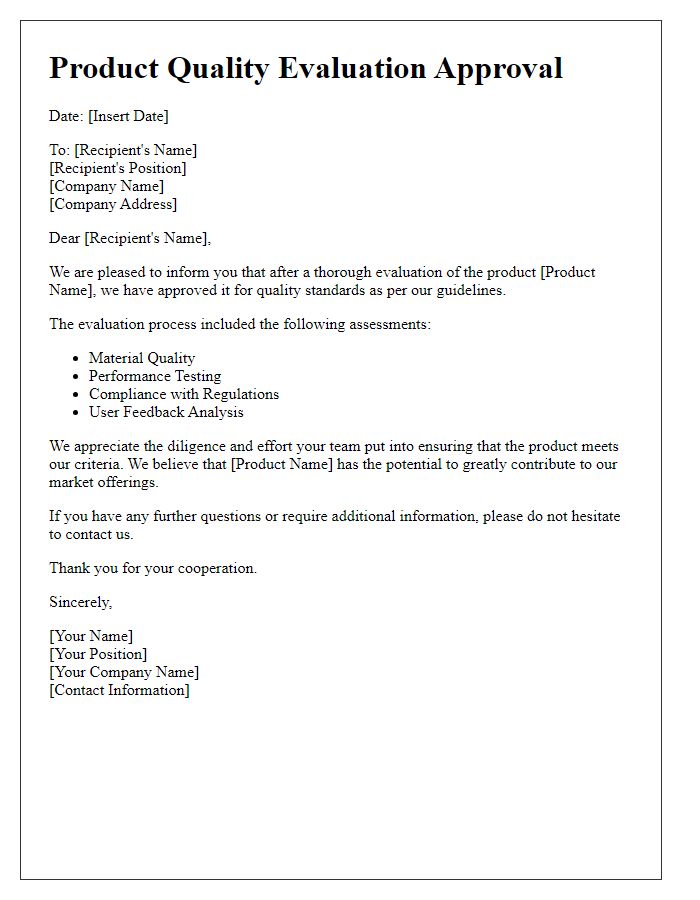

Quality Standards and Criteria

Quality assessment authorization for product evaluation should adhere to established standards and criteria set forth by regulatory bodies. These standards encompass industry benchmarks, such as ISO (International Organization for Standardization) guidelines, which specify parameters for quality management systems. Specific criteria must include material specifications, performance metrics, and compliance with safety regulations (e.g., CE marking in Europe, FCC regulations in the United States). Organizations must implement rigorous testing protocols, including laboratory assessments and field evaluations, to ensure products meet or exceed expectations. Documentation of assessment results, traceability of testing processes, and periodic reviews of quality management practices are essential for maintaining compliance and ensuring consumer confidence in the product.

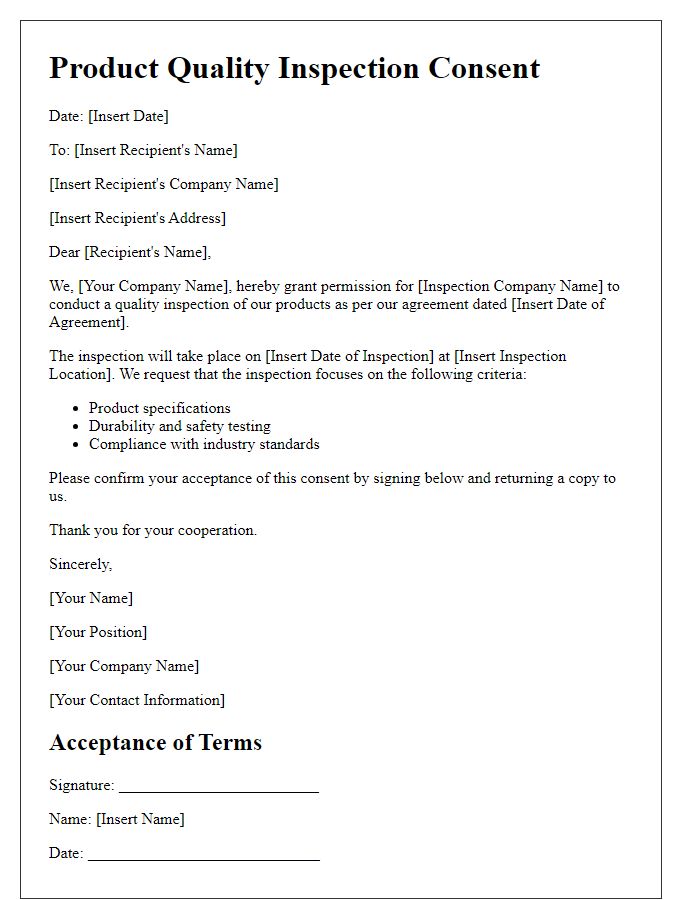

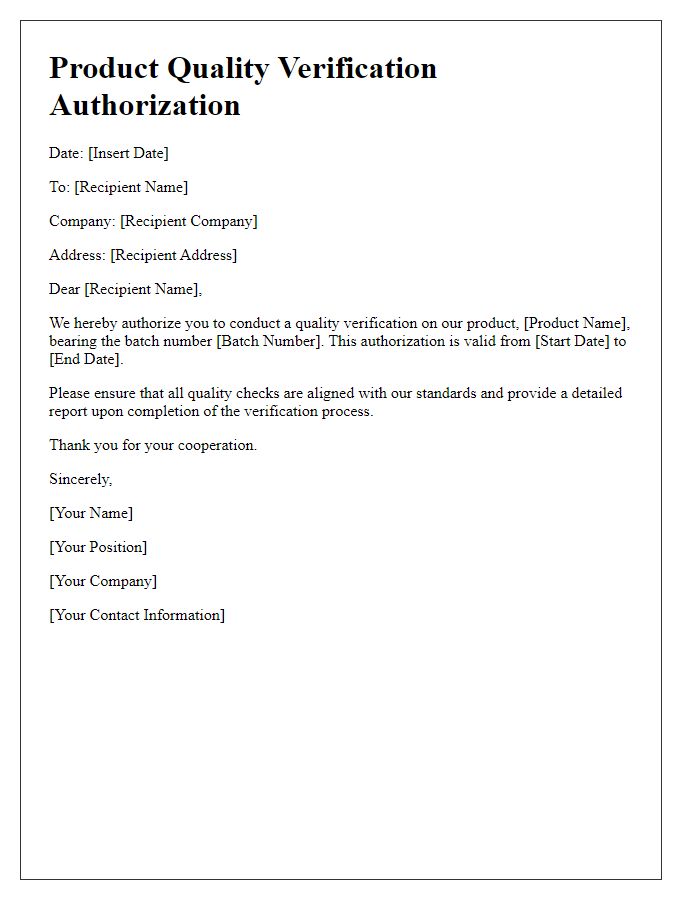

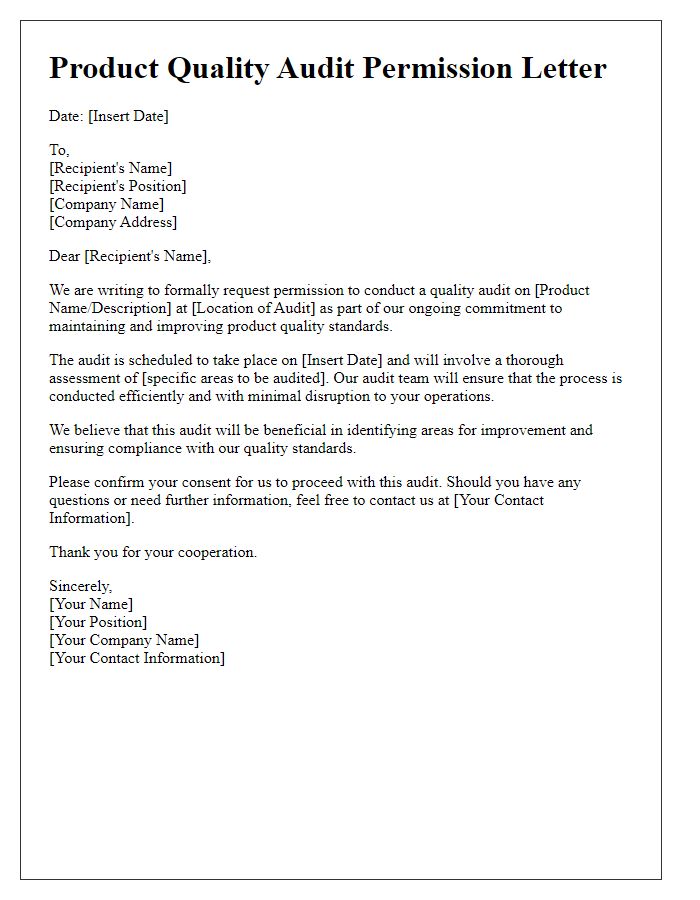

Authorization Scope and Limitations

Product quality assessment is essential for ensuring customer satisfaction and regulatory compliance. This assessment process typically includes evaluating materials, manufacturing processes, and finished products, focusing on specific guidelines and standards set by regulatory bodies such as ISO (International Organization for Standardization) or ASTM (American Society for Testing and Materials). The authorization scope encompasses inspecting production batches, conducting laboratory tests, and gathering product samples from various manufacturing sites, including factories in regions like Asia or Europe. Limitations may arise from geographic constraints, such as remote locale availability or specific equipment needed for testing, which can restrict the scope of monitoring. Furthermore, confidentiality agreements may limit the sharing of sensitive quality data with external parties, ensuring proprietary information remains protected during the assessment process.

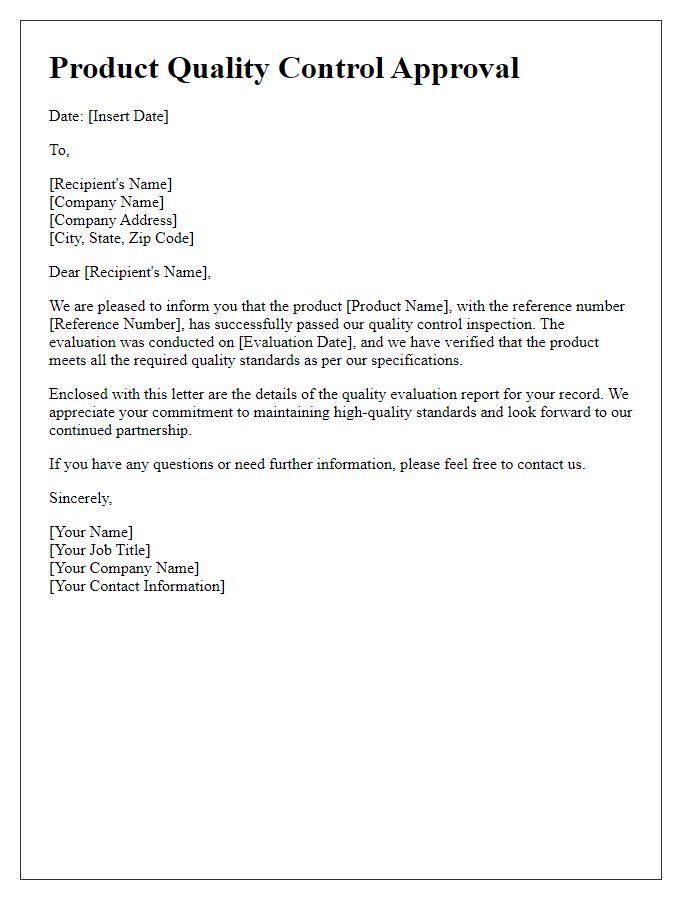

Contact Information and Signatures

Product quality assessment authorization forms incorporate crucial elements such as contact information, signatures, and relevant details pertaining to evaluation. The contact information should include the full name of the requesting party, company name (if applicable), email address, and phone number for effective communication. Signatures are essential for legal validation and authorization, demonstrating consent from responsible parties in the product quality assessment process. Specific products or services involved in the assessment should be clearly identified, alongside any pertinent dates, such as submission or assessment deadlines. This documentation streamlines the quality assessment process, ensuring accountability and traceability throughout evaluation procedures.

Comments