Are you looking to streamline your logistics operations and enhance your delivery efficiency? In today's fast-paced world, having an accurate delivery volume forecast is crucial for businesses to meet customer expectations and improve supply chain management. By predicting demand trends and adjusting your resources accordingly, you can avoid costly delays and ensure timely deliveries. Dive into our article to discover essential tips and strategies for creating an effective delivery volume forecast!

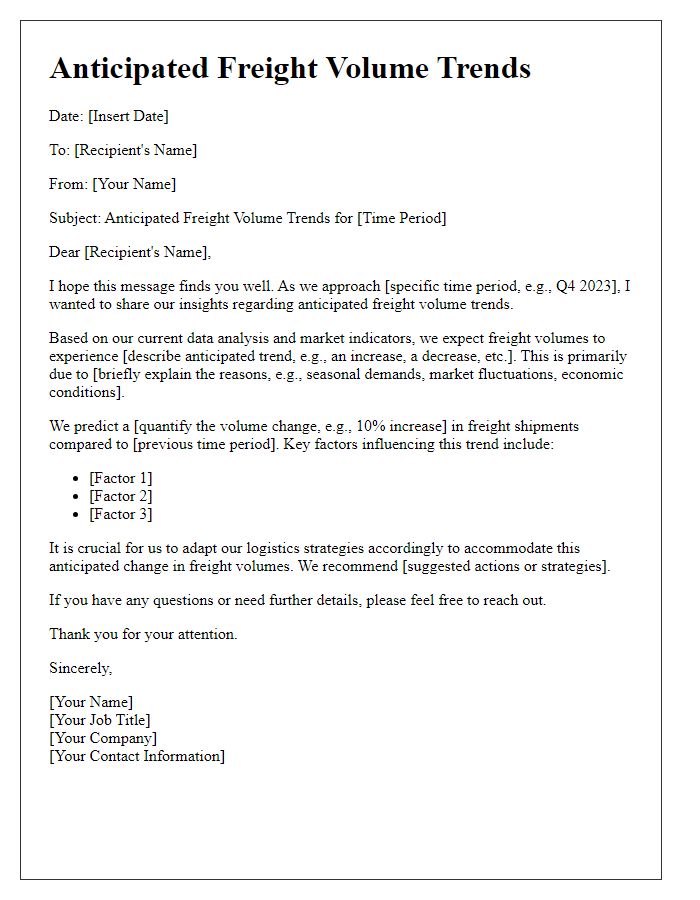

Clear Subject Line

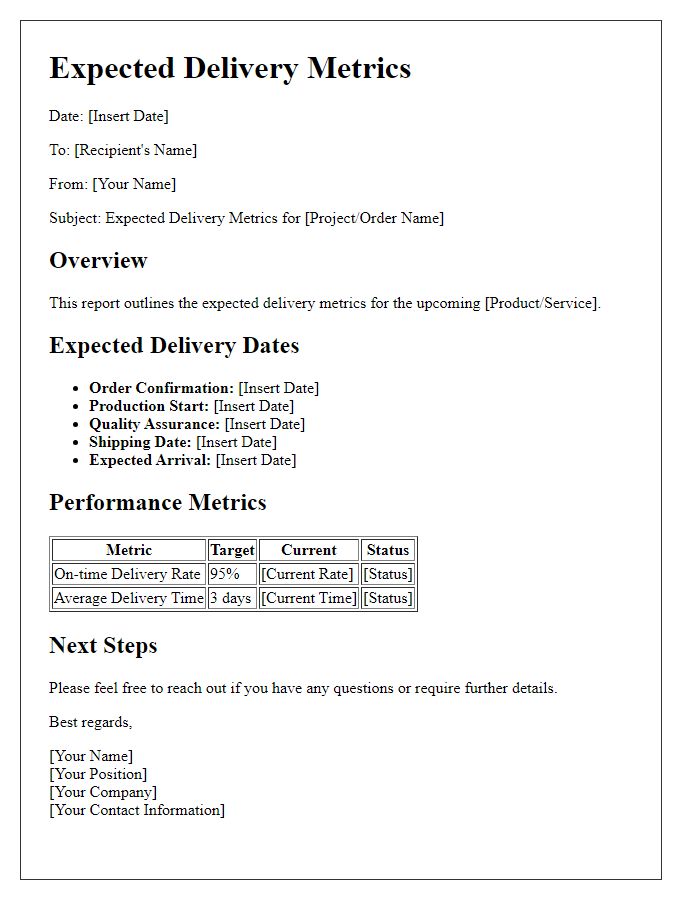

Accurate delivery volume forecasting is essential for logistics companies managing inventory and order fulfillment efficiently. Forecasting methods, such as historical data analysis and trend identification, can help predict future delivery volumes. Seasonal variations, like holiday peaks in November and December, require adjustments to ensure adequate staffing and vehicle capacity. Advanced analytics tools and software can enhance predictive accuracy, offering insights into customer behavior patterns. Stakeholders, including supply chain managers and logistics coordinators, benefit from clear communication of forecasted volumes to optimize resource allocation. An effective forecast can lead to reduced operational costs and improved customer satisfaction.

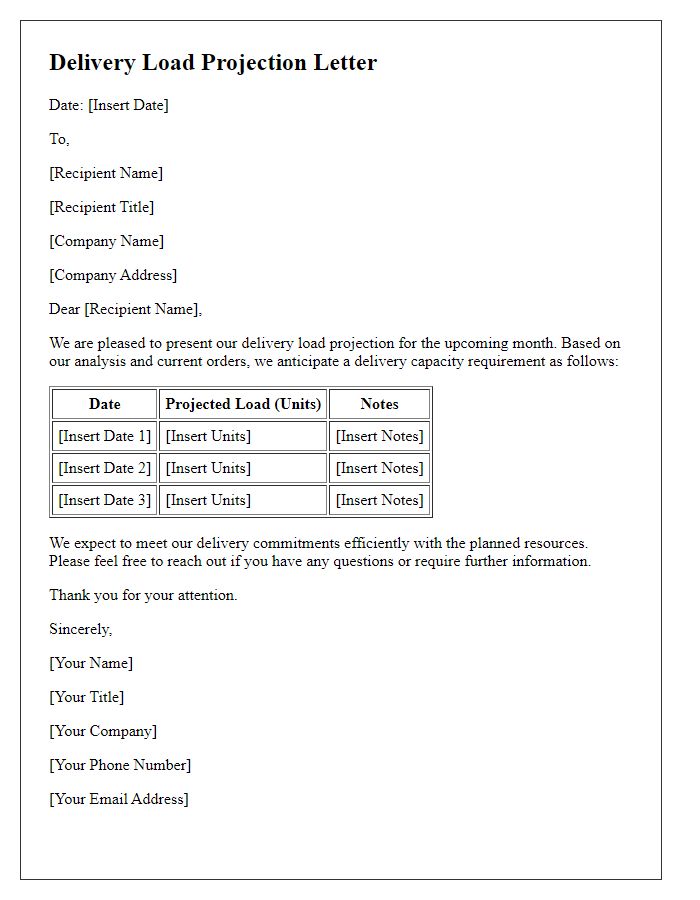

Forecasted Delivery Volumes

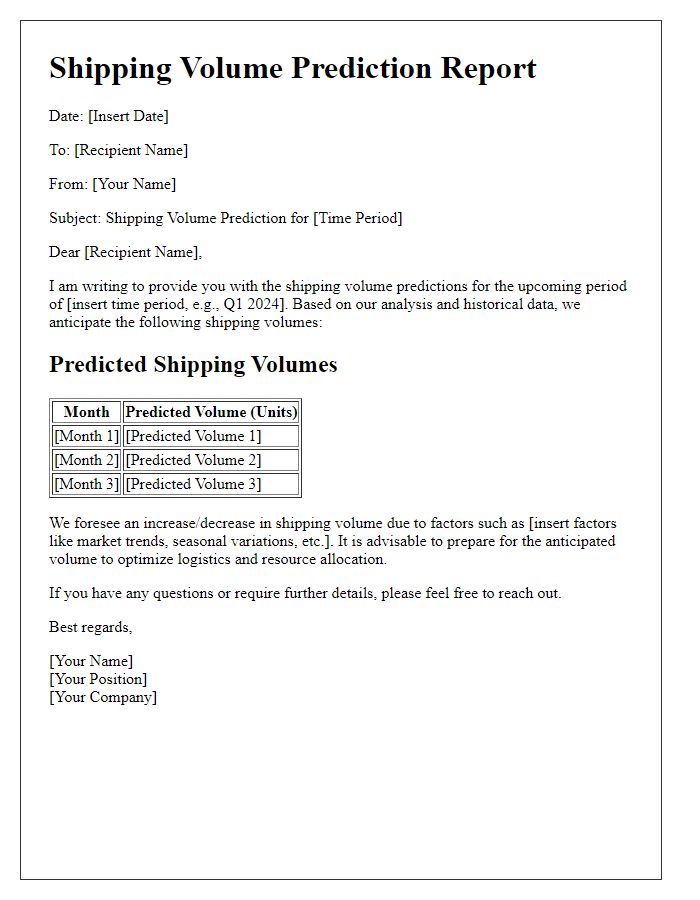

Forecasted delivery volumes are critical for optimizing logistics management and ensuring supply chain efficiency. Companies, such as FedEx and UPS, analyze historical data, market trends, and seasonal fluctuations to predict volume increases or decreases. For instance, during the holiday season (e.g., November to December), delivery volumes can surge by over 30% compared to regular months due to heightened consumer demand. Geographic factors, like urban areas versus rural locations, also influence delivery patterns, necessitating tailored strategies. An accurate volume forecast enables resource allocation, staff scheduling, and inventory management, ultimately enhancing customer satisfaction through timely deliveries.

Supporting Data and Analysis

Delivery volume forecasts require meticulous analysis of historical shipment data, market trends, and seasonal variations. Historical shipment data, for instance, from Q1 to Q4 in 2022, provides valuable insights into peak delivery months, highlighting significant spikes in June and December due to holiday shopping surges. Regional demand analysis indicates that urban areas, such as New York City and Los Angeles, experience higher delivery volumes compared to rural regions, affecting logistics planning. Additionally, incorporating market trends, such as the growth of e-commerce platforms like Amazon (which saw a 29% increase in 2022), can further refine forecasts. Lastly, external factors, including economic indicators like inflation rates and fuel prices, alongside planned promotional events or product launches, contribute to fluctuations in delivery demand projections, enabling accurate and strategic supply chain management.

Impact on Operations and Budget

Delivery volume forecasting is essential for efficient logistics operations in organizations like Amazon. Accurate predictions enable appropriate resource allocation, optimizing labor costs, transportation expenses, and inventory management. For instance, peak seasons such as Black Friday or Cyber Monday can lead to a surge in delivery volumes, necessitating hiring additional staff and increasing transportation capacity, which could impact the overall operational budget. Additionally, discrepancies in forecasted versus actual delivery volumes can result in excess inventory costs or customer dissatisfaction due to delays. Proper forecasting not only supports budget adherence but also enhances customer experience by ensuring timely deliveries, critical for maintaining competitive advantage.

Call to Action or Next Steps

Forecasting delivery volumes requires analyzing historical data, market trends, and seasonal fluctuations. For instance, in the retail sector, holiday demand spikes, especially during Black Friday and Cyber Monday, can double or triple shipping volumes (from previous months averaging 10,000 packages daily). Understanding regional differences (e.g., urban versus rural areas) also informs logistical strategies. Tracking metrics such as lead times (time between order placement and delivery) and customer satisfaction ratings helps optimize operations for greater efficiency and reliability. This comprehensive approach allows businesses to proactively meet customer expectations and adapt to changing demands.

Comments