Hey there! If you've ever experienced the frustration of unexpected repairs, you know how important proactive maintenance can be. It's not just about fixing problems; it's about preventing them from happening in the first place. In this article, we'll share some practical tips and insights to help you keep everything running smoothly and save you time and money in the long run. So, if you're ready to take charge of your maintenance routine, keep reading to discover how to stay ahead of the game!

Personalization and recipient details

Proactive maintenance ensures optimal performance and longevity of crucial equipment, such as HVAC systems in commercial buildings. Regular inspections (recommended every six months) can identify potential issues, preventing costly breakdowns. Filters, such as HEPA or MERV rated, should be replaced to ensure air quality and efficiency. Additionally, cleaning evaporator and condenser coils enhances energy efficiency, potentially reducing utility bills by up to 30%. A well-maintained system also improves indoor air quality, essential for occupant health and comfort in spaces like office buildings or schools. Early detection of refrigerant leaks can prevent extensive damage, maintaining the system's performance and reliability over time.

Clear subject line and introduction

Proactive maintenance refers to the strategic approach taken by organizations to regularly scheduled upkeep and inspections to prevent equipment failure and unexpected breakdowns. Implementing a proactive maintenance program can increase the lifespan of machinery, such as manufacturing equipment in factories or HVAC systems in commercial buildings. Regular checks, such as visual inspections and component replacements, should occur at predetermined intervals based on manufacturer recommendations. Additionally, the use of advanced technologies like IoT sensors allows for real-time monitoring of machinery health, providing data analytics that can predict potential failures before they occur. This preventive strategy can significantly reduce repair costs and downtime, enhancing overall operational efficiency.

Maintenance benefits and importance

Proactive maintenance enhances equipment longevity and operational efficiency across various industries such as manufacturing and aviation. Regular inspections, often scheduled monthly or quarterly, can identify potential issues before they escalate, thereby preventing costly downtime. For instance, in aerospace, routine checks of critical systems like avionics and engines (with replacement costs averaging millions of dollars) are vital for ensuring safety and compliance with regulations established by authorities like the Federal Aviation Administration (FAA). Additionally, maintaining HVAC (Heating, Ventilation, and Air Conditioning) systems in commercial buildings can improve energy efficiency, with potential savings of up to 30% on utility bills. The practice fosters a culture of safety and reliability, ultimately leading to better performance and reduced operational costs.

Detailed maintenance recommendations

Proactive maintenance is essential for prolonging the lifespan of machinery and ensuring optimal performance in industrial environments. Regular oil changes (every 3,000 miles or every three months) prevent engine wear in vehicles, while equipment lubrication (at least monthly) minimizes friction in moving parts, extending life expectancy. Inspecting belts and hoses quarterly can identify early signs of wear, reducing the risk of breakdowns. Furthermore, scheduling routine inspections (every six months) for safety and functionality allows for timely repairs, preventing costly downtimes. Cleaning air filters (monthly) enhances airflow efficiency, reducing energy consumption. Monitoring fluid levels (weekly) ensures machines operate within safe parameters, minimizing wear and risk of failure. Implementing a detailed maintenance schedule promotes system reliability and boosts overall productivity.

Call to action and contact information

Proactive maintenance plays a crucial role in ensuring the longevity and optimal performance of essential equipment. Regularly scheduled checks can prevent unexpected breakdowns and costly repairs. For instance, HVAC systems (Heating, Ventilation, and Air Conditioning) benefit from seasonal servicing, which can enhance energy efficiency by up to 30%. Implementing lubrication for moving parts in machinery reduces wear, thereby extending operational lifespan. To ensure you receive timely maintenance, contacting your service provider at least once a quarter is recommended. Reach out to our experienced team at 123-456-7890 or email support@yourservicecompany.com for expert assistance. Investing in proactive maintenance today can save significant costs tomorrow.

Letter Template For Proactive Maintenance Advice Samples

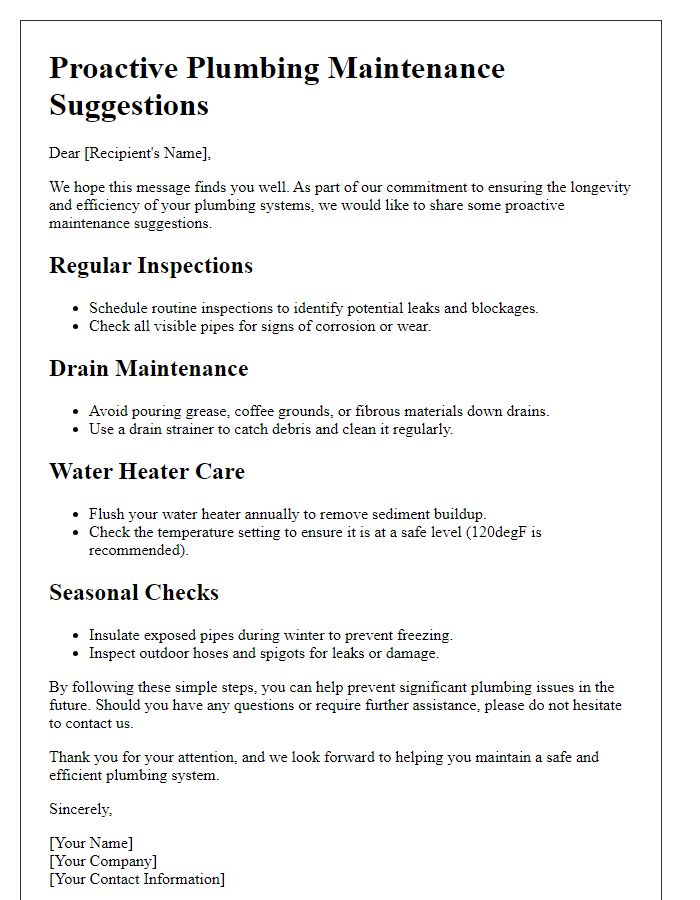

Letter template of proactive maintenance suggestions for plumbing systems.

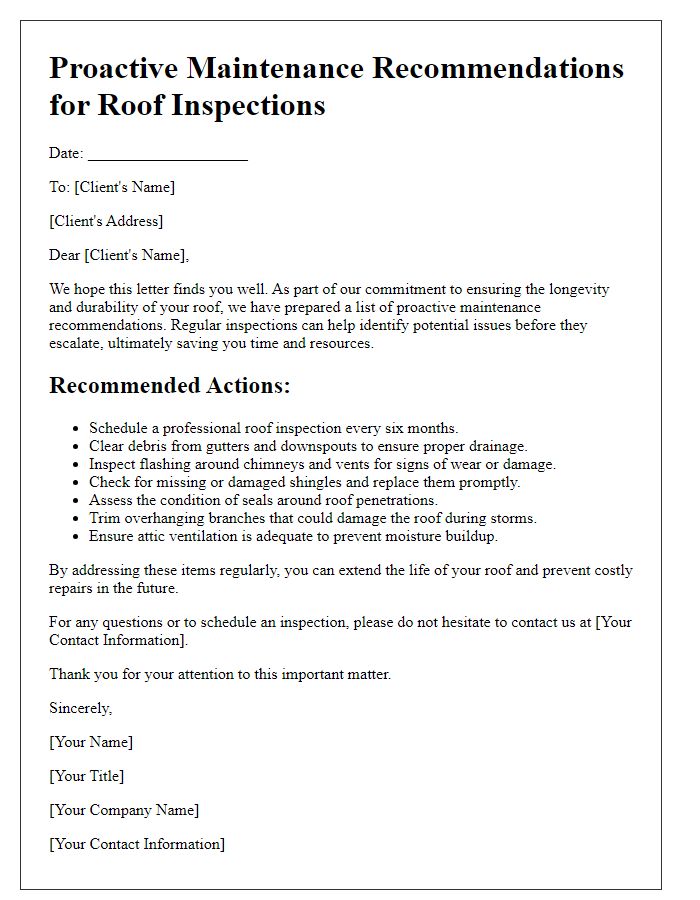

Letter template of proactive maintenance recommendations for roof inspections.

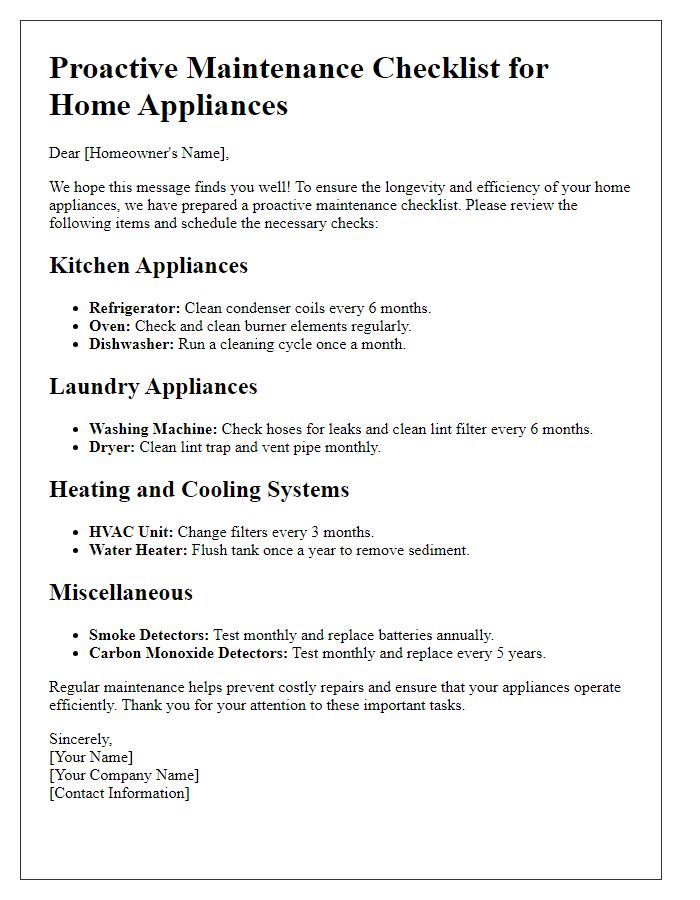

Letter template of proactive maintenance checklists for home appliances.

Letter template of proactive maintenance alerts for commercial equipment.

Comments