Hey there! Staying on top of maintenance schedules can often feel like a daunting task, but it doesn't have to be. With the right updates and reminders, you can ensure everything runs smoothly and efficiently. Curious about how to streamline your maintenance processes and keep everything in check? Let's dive into the details!

Clear subject line

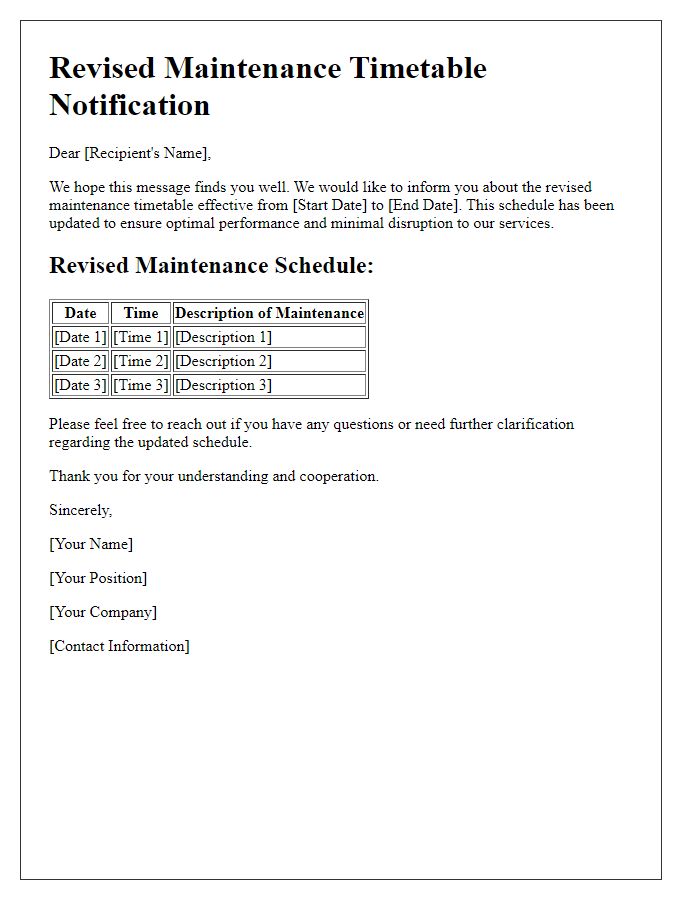

Scheduled Maintenance Update: Important Dates and Information Scheduled maintenance sessions are essential for ensuring the smooth operation of various systems and equipment. For instance, the upcoming maintenance for HVAC systems at City Hall in Springfield will occur on November 15, 2023, from 8 AM to 4 PM. This will involve routine checks and filter replacements, ensuring optimal air quality and climate control for occupants. Similarly, network maintenance for the municipal broadband infrastructure is scheduled for November 18, 2023, between 10 PM and 2 AM, aimed at boosting internet reliability and speed for local residents. Users may experience brief outages during these times, so awareness is crucial for avoiding inconvenience.

Precise date and time

The annual maintenance schedule for the HVAC system at the downtown office building (located at 123 Main Street, Springfield) has been updated to occur on October 15, 2023, from 9:00 AM to 2:00 PM. This maintenance process includes thorough inspections of the air conditioning units, replacement of filters, and checks for any refrigerant leaks. The scheduled maintenance will ensure optimal performance and energy efficiency, reducing the risk of unexpected breakdowns during the colder months. All employees are advised to refrain from using the heating system during this timeframe to facilitate a smooth and efficient maintenance operation.

Detailed maintenance tasks

A comprehensive maintenance schedule is crucial for the effective operation of machinery and facilities. Scheduled tasks include lubrication of moving parts in engines, essential to prevent friction-related damage, and inspection of electrical connections, vital for safe operation. Cleaning filters in HVAC systems (heating, ventilation, and air conditioning) is critical to maintaining air quality, with recommended cleaning intervals every three months. Routine inspections of fire extinguishers are required to ensure accessibility and functionality, with compliance checks mandated annually. Additionally, testing emergency lights should occur every six months to guarantee reliable performance during power outages. Maintenance of safety equipment, including personal protective equipment (PPE) like helmets and gloves, is necessary for worker safety and should be replaced as per manufacturer guidelines. Adhering to these detailed tasks promotes efficiency, longevity, and safety throughout operations.

Contact information

Regular maintenance schedules are vital for ensuring optimal performance and longevity of equipment or facilities. Scheduling updates should include specific contact information, such as the maintenance manager's name (John Doe), phone number (555-123-4567), and email address (johndoe@maintenanceco.com). Clear communication channels facilitate quick response times for any maintenance-related inquiries or issues. Moreover, including the service frequency, such as monthly checks or quarterly overhauls, enhances clarity for all stakeholders involved in the maintenance process. Addressing critical components, like HVAC systems or machinery, ensures that everyone understands the significance of each scheduled maintenance task. Overall, well-structured contact information is crucial for an effective maintenance schedule.

Safety precautions

Regular maintenance schedules play a crucial role in ensuring optimal performance for machinery and equipment while prioritizing safety precautions. Scheduled inspections, typically occurring quarterly, focus on critical components such as brake systems, which must adhere to industry standards, often outlined by organizations like the Occupational Safety and Health Administration (OSHA). Technicians conduct thorough evaluations, checking for wear and tear, particularly in high-use environments like manufacturing facilities. Proper training for maintenance personnel is essential, facilitating an understanding of safety protocols, use of personal protective equipment (PPE), and adherence to lockout/tagout procedures. This minimizes risks, such as unexpected machinery start-up during servicing, thereby safeguarding workers. Overall, consistent maintenance not only enhances equipment reliability but also fosters a culture of safety within the organization.

Comments