When it comes to ensuring the reliability of our suppliers, a thorough risk assessment is essential. Following up on our previous discussions, we aim to reinforce our commitment to quality and security in our supply chain. Understanding potential risks not only protects our business but also fosters a stronger partnership with our suppliers. So, if you're curious about how we can enhance our collaboration and mitigate risks together, read on!

Supplier identification and contact details

Supplier identification involves gathering essential information about the vendor, including the company name, registration number, and primary business address. Contact details should include key personnel such as the account manager, procurement officer, or other relevant representatives. Important contact information should encompass direct phone numbers, email addresses, and possibly emergency contact numbers for urgent communication needs. Understanding geographical considerations, such as country-specific risk factors or compliance regulations, is also critical in supplier relationships. Detailed and accurate supplier information supports effective risk assessments and enhances collaboration.

Summary of identified risks

The supplier risk assessment, conducted on October 5, 2023, revealed several critical risks associated with supply chain vulnerabilities. Financial instability was noted, with the supplier's credit rating falling into the lower tier, specifically below 650, signaling potential cash flow issues. Operational risks were identified related to insufficient quality control measures at their manufacturing facility located in Shenzhen, China, raising concerns about product consistency and compliance with industry standards. Additionally, geopolitical risks emerged due to ongoing trade tensions between the United States and China, potentially disrupting the supply of key components vital for production. Environmental risks were also highlighted; the supplier's location in a flood-prone area has resulted in previous production delays, impacting timelines. Mitigation strategies are necessary to address these risks effectively and ensure robust supply chain continuity.

Follow-up actions and deadlines

Supplier risk assessments evaluate potential vulnerabilities within a supply chain, ensuring compliance and reliability. Identifying key actions, specific deadlines (such as the end of the quarter on March 31, 2024), and responsible parties enhances accountability. For instance, a critical action item may involve updating supplier contracts to include stringent terms regarding data security breaches. Additionally, implementing regular audits every six months can help monitor supplier performance and risks effectively. Establishing clear metrics for evaluation, such as on-time delivery rates above 95% and incident reporting within 48 hours, can further mitigate risks related to supply chain disruptions.

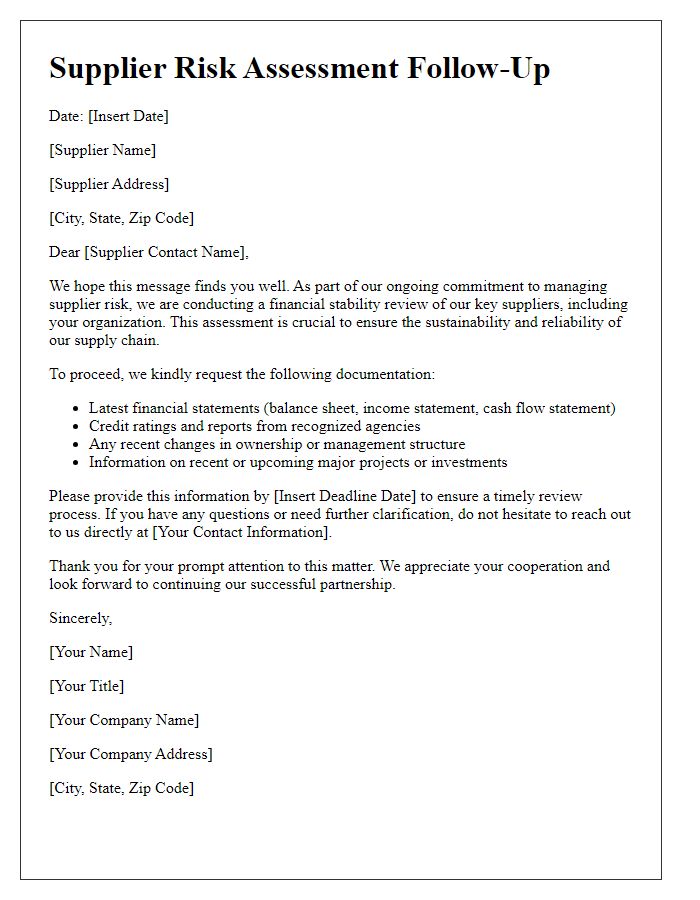

Request for updated documentation

Supplier risk assessments are crucial for ensuring compliance and minimizing potential disruptions in the supply chain. Companies often request updated documentation from suppliers to maintain accurate risk profiles and assess changes in operational practices. Current regulations, such as ISO 9001 (Quality Management Systems) and ISO 27001 (Information Security Management), necessitate the periodic review of supplier practices. Updated documents may include certificates of compliance, financial statements, and recent audits, which provide insight into the supplier's stability and adherence to industry standards. Furthermore, a thorough assessment of factors like cybersecurity measures and environmental, social, and governance (ESG) practices can identify potential vulnerabilities, fostering stronger partnerships and enhancing supply chain resilience.

Assurance of supplier collaboration and improvement initiatives

Supplier collaboration plays a vital role in mitigating risks associated with supply chain management, emphasizing proactive communication and transparency. Improvement initiatives, such as joint workshops or audits, can identify areas where suppliers need assistance in meeting quality standards and compliance regulations. Regular assessments contribute to building trust and enhancing overall performance. For instance, implementing key performance indicators (KPIs) tailored to supplier capabilities enables clearer benchmarks for evaluation. Collaborations with suppliers in training programs or technology upgrades can bolster operational efficiency and reduce risk factors significantly. In turn, these efforts lead to stronger partnerships, ensuring reliability and fostering continuous improvement across all aspects of supplier relationships.

Letter Template For Supplier Risk Assessment Follow-Up Samples

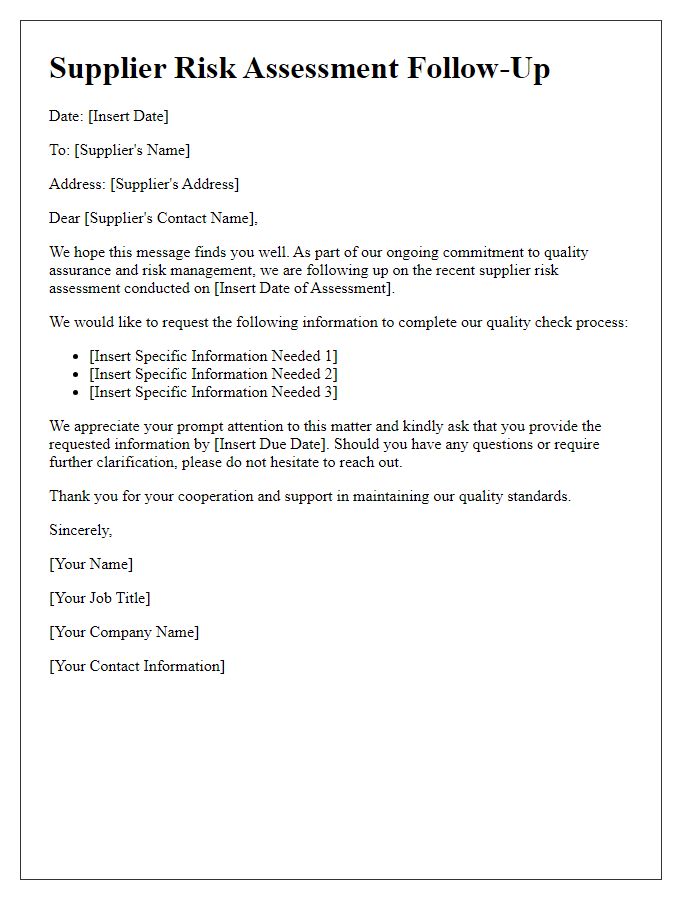

Letter template of supplier risk assessment follow-up for quality check.

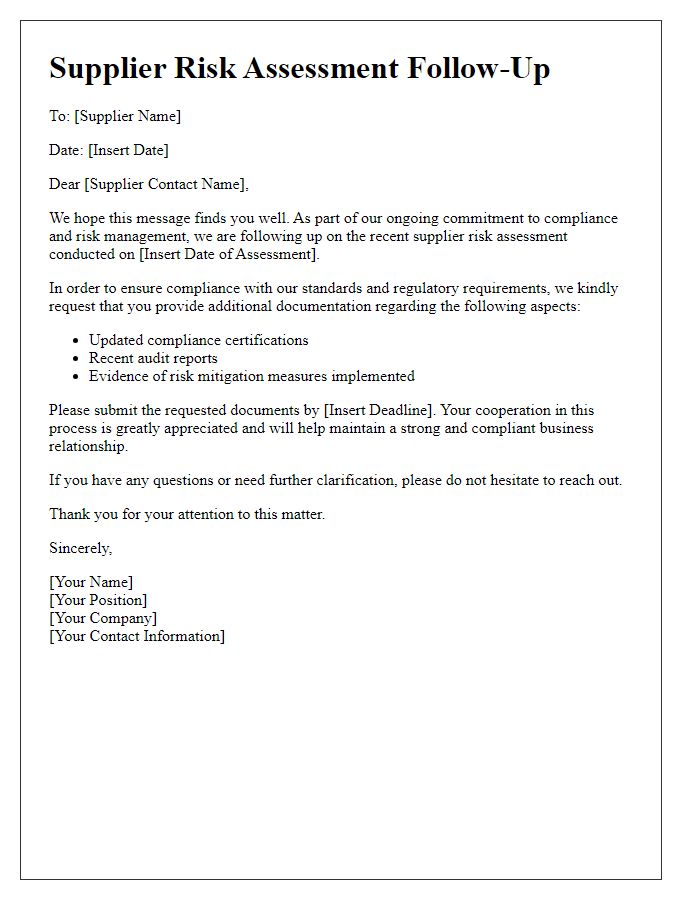

Letter template of supplier risk assessment follow-up for compliance verification.

Letter template of supplier risk assessment follow-up for financial stability review.

Letter template of supplier risk assessment follow-up for performance monitoring.

Letter template of supplier risk assessment follow-up for contract renewal discussions.

Letter template of supplier risk assessment follow-up for incident reporting.

Letter template of supplier risk assessment follow-up for sustainability practices evaluation.

Letter template of supplier risk assessment follow-up for cybersecurity measures assessment.

Letter template of supplier risk assessment follow-up for supply chain disruptions.

Comments