When it comes to packaging standards, the relationship between suppliers and businesses is crucial for maintaining quality and efficiency in the supply chain. Understanding and adhering to specific packaging guidelines not only ensures product safety but also promotes sustainability and compliance with industry regulations. In this article, we'll explore essential packaging standards that every supplier should consider and how they can positively impact operational success. So, let's dive in and discover effective strategies to enhance your packaging processes!

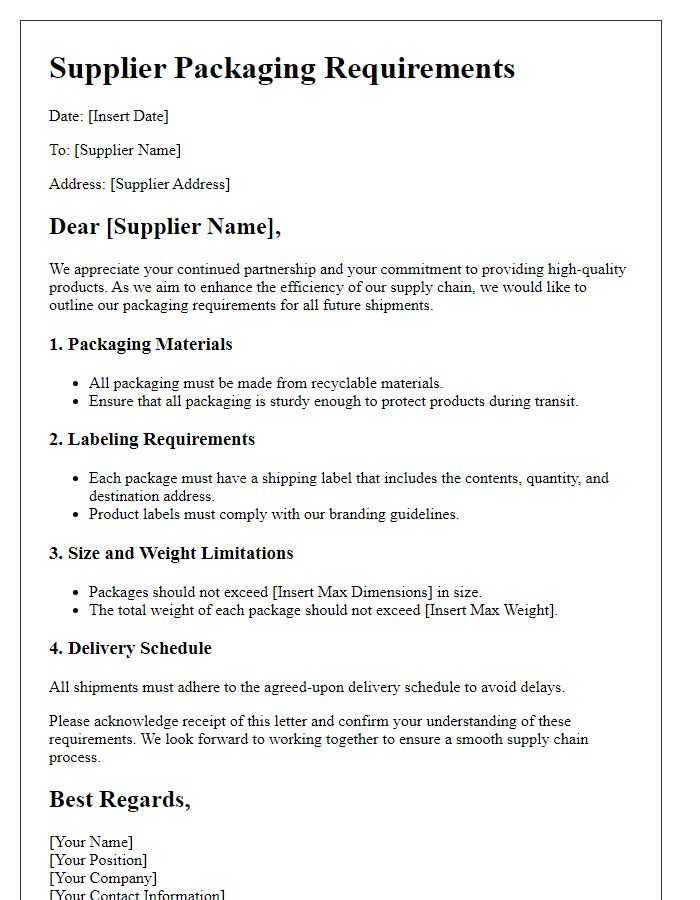

Branding and Labeling Requirements

To maintain brand integrity and comply with industry standards, packaging for products must meet specific branding and labeling requirements. The packaging materials (such as cardboard, plastic, or glass) should reflect the company's commitment to sustainability and quality, adhering to environmentally friendly certifications like FSC or Recyclable labels. Labels must display essential product information clearly, including ingredients (with percentage breakdowns), allergens, weight (in both metric and imperial units), and expiration dates. Additionally, logos must be prominently featured, using approved color palettes and fonts to ensure brand consistency. QR codes should be embedded for quick access to digital content, such as promotional materials or usage instructions, enhancing customer engagement. Compliance with regulatory guidelines, such as FDA or EU regulations for food products, is crucial to avoid potential legal issues and ensure consumer safety. All elements of packaging should align with the overall marketing strategy to create a cohesive brand image across different platforms and product lines.

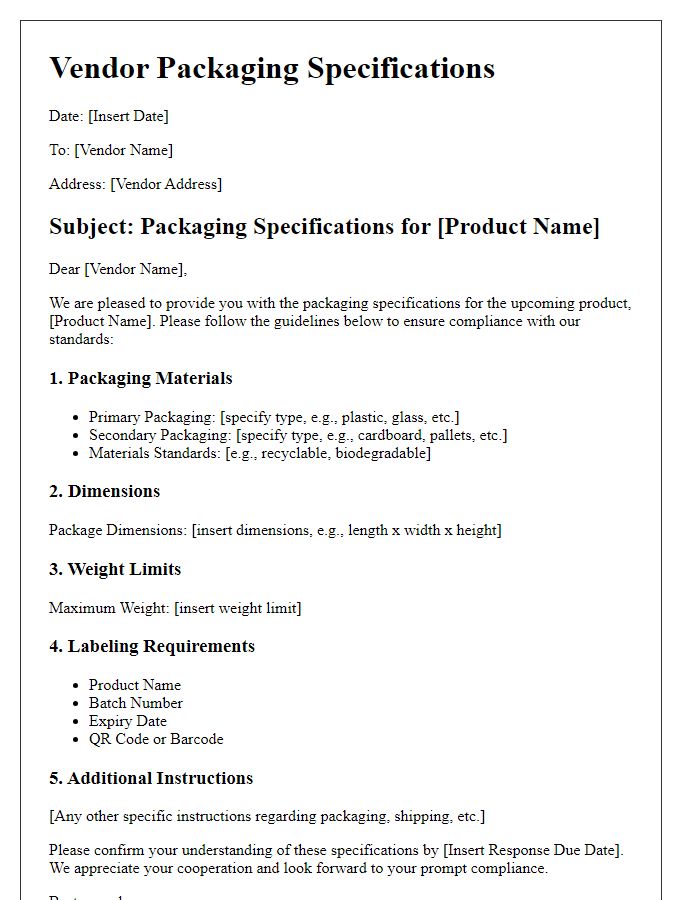

Material Specifications

Supplier packaging standards outline critical material specifications necessary for maintaining product integrity during transportation and storage. Common materials such as corrugated cardboard, plastic film, and foam cushioning serve distinct purposes, ensuring protection against impact and moisture. For instance, biodegradable options like recycled paper meet sustainability goals while maintaining stability in humid conditions (at least 90% relative humidity). Additionally, weight restrictions (usually under 30 pounds per package) contribute to efficient handling process, minimizing risk of accidents. Compliance with health and safety regulations, such as FDA standards for food packaging materials, ensures that products remain safe for consumer use. Packaging dimensions must align with shipping guidelines to optimize space utilization (typically 48 x 40 inches for pallets), reducing transportation costs and environmental footprint.

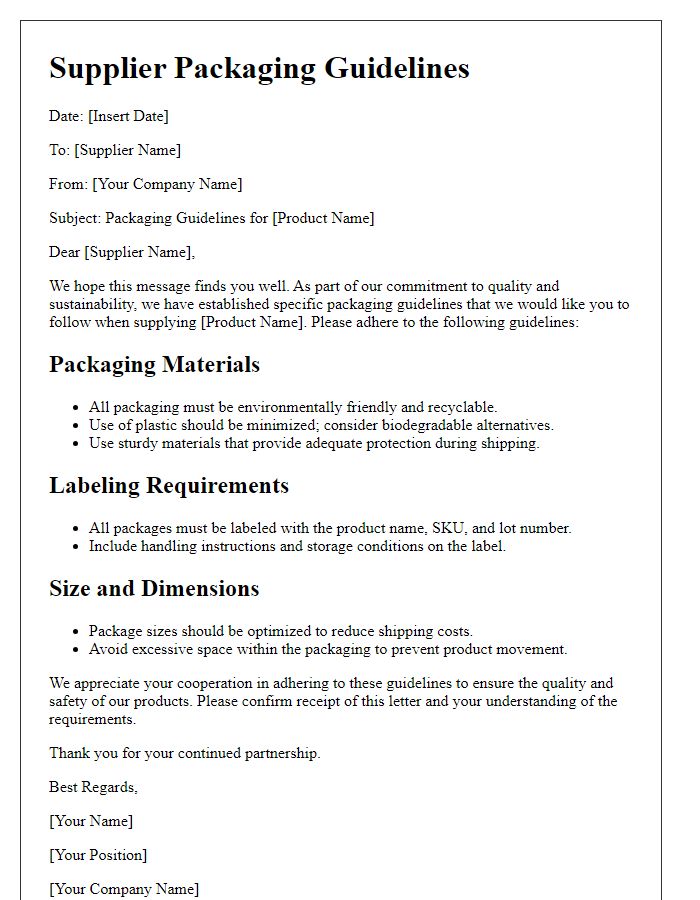

Environmental and Sustainability Standards

Supplier packaging standards are crucial for promoting environmental and sustainability practices within the supply chain. Adhering to guidelines, such as using recyclable materials (like cardboard or biodegradable plastics), ensures that packaging minimizes landfill waste. For instance, the European Union (EU) has set a target to reuse or recycle 70% of packaging by 2030. This includes optimizing logistics by reducing excess packaging weight, which contributes to lower carbon emissions during transportation. Implementing eco-friendly inks and dyes also reduces harmful chemicals entering ecosystems. Additionally, certifications such as ISO 14001 exemplify commitment to sustainable environmental management and can enhance a company's reputation. Overall, integrating these standards reduces the ecological footprint of packaging while meeting consumer demand for sustainable products.

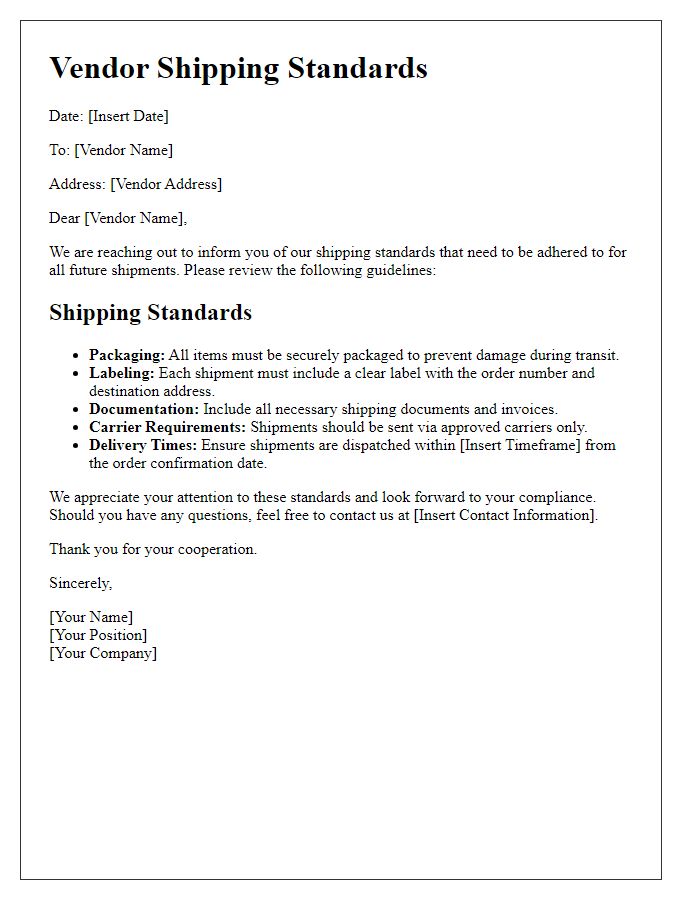

Packaging Dimensions and Design

Supplier packaging standards play a crucial role in maintaining product integrity and optimizing space during shipping and storage. Proper packaging dimensions, such as length, width, and height (measured in centimeters), should align with industry regulations, ensuring minimal waste and maximum efficiency. Design elements, including structural integrity (utilizing materials like corrugated cardboard or biodegradable plastics), must protect the product from damage due to environmental factors such as moisture and pressure during transit. Clear labeling, including handling instructions and compliance symbols, enhances identification and quality control processes, allowing for seamless integration into supply chain operations. Adherence to these standards ensures consistency across various products and vendors while meeting requirements established by organizations like the International Organization for Standardization (ISO).

Quality Assurance and Testing Procedures

Supplier packaging standards, particularly in the context of Quality Assurance (QA) and Testing Procedures, are essential for maintaining product integrity during transportation and storage. These standards outline specific requirements for materials such as corrugated cardboard, foam inserts, and shrink-wrap, ensuring they meet industry benchmarks for durability and protection. Testing procedures must include compression tests, drop tests, and temperature resistance evaluations to validate that packaging can withstand logistical challenges. Additionally, compliance with regulatory frameworks, like ISO 9001, is essential for quality management systems, which further guarantees that packaging practices align with international standards. Regular audits and documentation reviews will ensure that suppliers consistently adhere to these packaging standards, ultimately safeguarding the quality of goods throughout the supply chain.

Comments