Are you struggling to keep tabs on your inventory levels with your suppliers? Efficient inventory management is essential for any business looking to streamline operations and reduce costs, yet it can often feel overwhelming. In this article, we'll explore effective strategies for communicating your inventory needs and maintaining strong relationships with your suppliers. So, are you ready to enhance your inventory management game? Let's dive in!

Clear subject line

Efficient inventory management is crucial for maintaining a seamless supply chain in various industries. Suppliers need to track inventory levels accurately, ensuring that stock levels meet demand without excess. Key inventory metrics include the reorder point, which indicates when to restock; lead time, the duration from order to delivery; and safety stock, a buffer against unexpected demand spikes. Effective management systems often utilize software solutions for real-time tracking, facilitating better decision-making based on data analytics. By maintaining clear communication and accurate records, suppliers can optimize their processes and prevent unnecessary delays or shortages, ultimately leading to improved customer satisfaction.

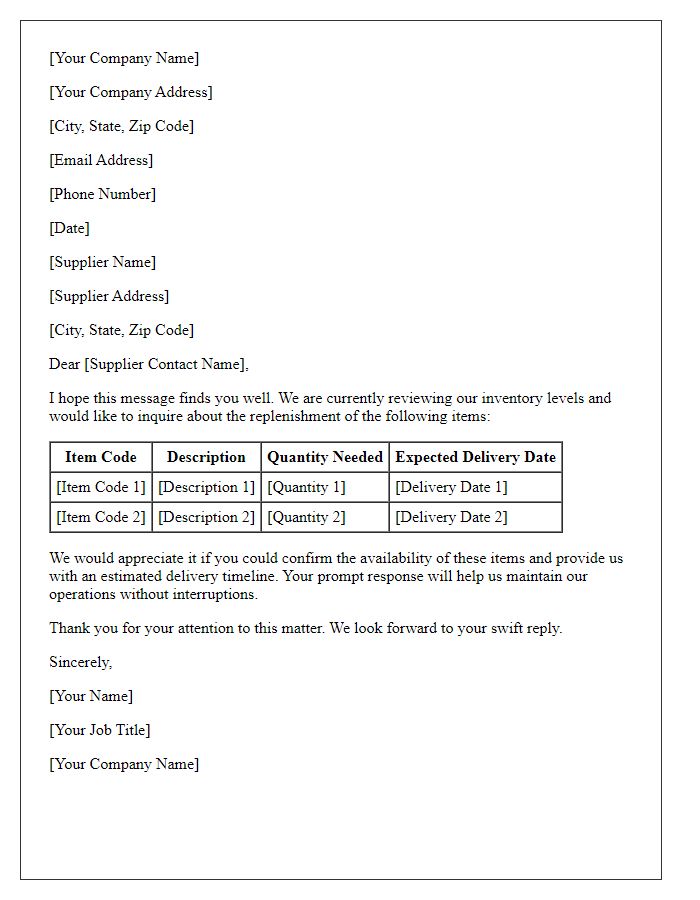

Supplier contact information

Effective supplier inventory management requires precise communication channels. Accurate supplier contact information is crucial for seamless collaboration. This includes details such as the supplier's name, including company designation, phone number for direct inquiries, email address for formal communication, and physical address for shipping and receiving inventory. Additionally, including points of contact (such as a designated account manager) ensures timely responses to queries or issues related to stock levels. Proper documentation of this information can significantly enhance ordering processes and inventory tracking efficiencies.

Request for inventory details

Efficient inventory management is crucial for maintaining optimal stock levels in supply chain operations. For instance, accurate inventory counts provide insights into product availability, such as fast-moving consumer goods (FMCG) or electronics, helping avoid stockouts or overstock situations. Conducting regular audits and utilizing inventory management software can facilitate tracking items across warehouses, like those located in Los Angeles or New York City. Timely reports on current stock levels, reorder points, and lead times from suppliers contribute to strategic planning and cost reduction. Additionally, seasonal demand fluctuations, such as those experienced during the holiday shopping season, necessitate ongoing communication with suppliers to ensure sufficient inventory to meet customer expectations.

Desired timeline and deadline

Effective inventory management is crucial for suppliers, particularly in industries like retail and manufacturing. Accurate tracking of stock levels helps prevent overstocking and stockouts, ensuring product availability for customers. For efficient operations, suppliers often utilize inventory management systems capable of real-time data analysis. Desired timelines typically involve regular updates on inventory status, ideally weekly or bi-weekly, to facilitate timely decision-making. Deadlines for specific inventory requests, such as reorder levels or new product introductions, should be clearly communicated, often set to align with planned sales cycles or seasonal demand fluctuations. Such proactive management helps maintain optimal inventory levels, ultimately enhancing customer satisfaction and operational efficiency.

Contact information for follow-up

Effective inventory management is crucial for suppliers to maintain optimal stock levels and meet customer demands. Precise tracking systems, such as Enterprise Resource Planning (ERP) software, can streamline processes significantly. Regular communication, including timely follow-ups and clear contact information, is essential for resolving discrepancies that may arise in orders or stock levels. An organized approach ensures that suppliers can address potential shortages, overages, and other inventory challenges. This ultimately enhances the supply chain efficiency and strengthens relationships with retailers or end-users.

Comments