Hey there! If you've ever faced the frustration of an unexpected machinery breakdown, you know how disruptive it can be to your operations. It often feels like you're thrown into chaos, scrambling to find solutions and keep everything on track. But don't worry, we're here to help you navigate this tricky situation with a well-crafted letter template that communicates effectively with all stakeholders. Ready to dive in and discover how to tackle this challenge head-on?

Subject Line: Urgent Notice: Unexpected Machinery Breakdown

Unexpected machinery breakdowns can disrupt operations significantly, especially in manufacturing facilities like those in Detroit. Instances such as a malfunctioning conveyor belt (common in automotive assembly lines) can halt production completely, leading to substantial financial losses--often thousands of dollars per hour. Prompt identification of the problem is crucial; for example, a breakdown on December 15, 2023, in a prominent automotive plant resulted in a three-day shutdown, affecting supply chains and delivery schedules. Maintenance teams must quickly assess causes (like worn-out bearings or software interface failures) to implement effective solutions and prevent further delays. Efficient communication regarding the situation is essential for all stakeholders involved in the production cycle.

Salutation: Address recipient appropriately

Unexpected machinery breakdowns can lead to significant impacts on productivity and financial losses within industrial settings, such as factories or manufacturing plants. For instance, a malfunctioning conveyor belt, due to a worn-out bearing, can halt assembly lines, resulting in downtime costing thousands of dollars per hour. Maintenance teams, often required to diagnose issues quickly, face challenges when spare parts, like motor components, are not readily available, prolonging repair times. Additionally, safety concerns arise if machinery, like hydraulic presses, fails unexpectedly, potentially jeopardizing worker safety. Swift communication regarding such breakdowns is crucial, prompting immediate action plans to limit disruption and ensure continuous operations.

Explanation: Briefly describe the issue and machinery involved

Unexpected machinery breakdown refers to the sudden failure of critical equipment, such as a hydraulic press or a conveyor belt, which can halt production processes in manufacturing plants. This incident typically occurs without warning, often due to wear and tear, mechanical fatigue, or unexpected usage conditions. For instance, a hydraulic press, operating under high pressure to shape metals, may experience a malfunction in its hydraulic system, leading to loss of pressure and functionality. Such breakdowns can result in significant downtime, affecting overall productivity and causing delays in meeting production deadlines. Immediate assessment and repairs are crucial to minimize operational disruptions and prevent further damage to the machinery.

Impact: Detail the potential effects on operations or timelines

Unexpected machinery breakdowns can significantly disrupt production schedules, leading to considerable downtime. Equipment such as CNC machines, essential for precision manufacturing, may require extensive repairs, which could extend delays by several days to weeks, depending on the parts' availability. This downtime can result in missed deadlines for client orders, thereby straining business relationships and potentially leading to financial losses ranging from thousands to millions of dollars. Moreover, the inability to maintain a steady output can affect inventory levels, causing shortages and impacting supply chains. In high-stakes industries like automotive or aerospace, these delays can also have regulatory implications, necessitating compliance reviews and additional inspections, adding further strain to operational timelines.

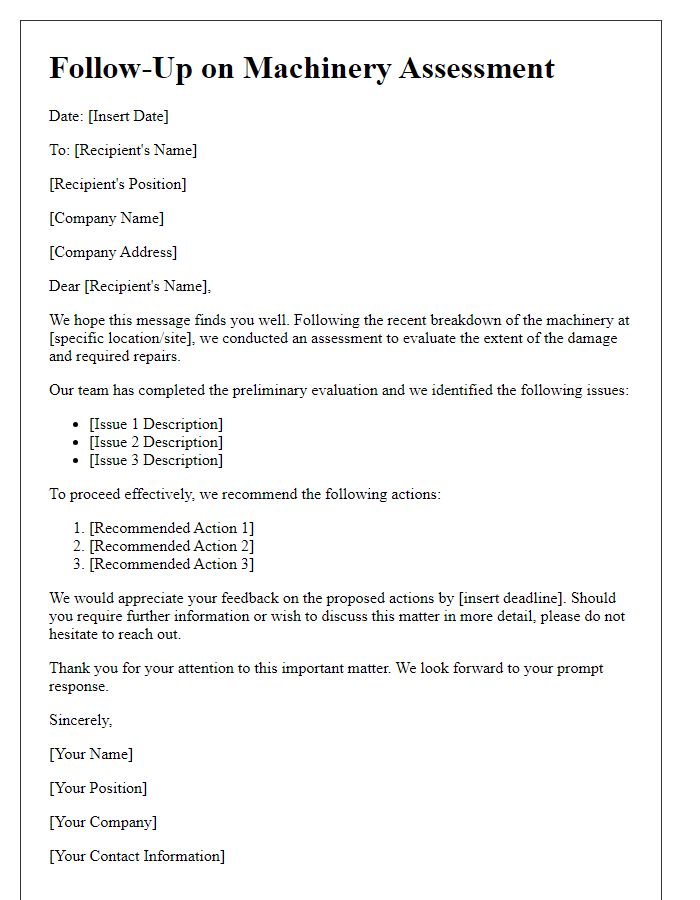

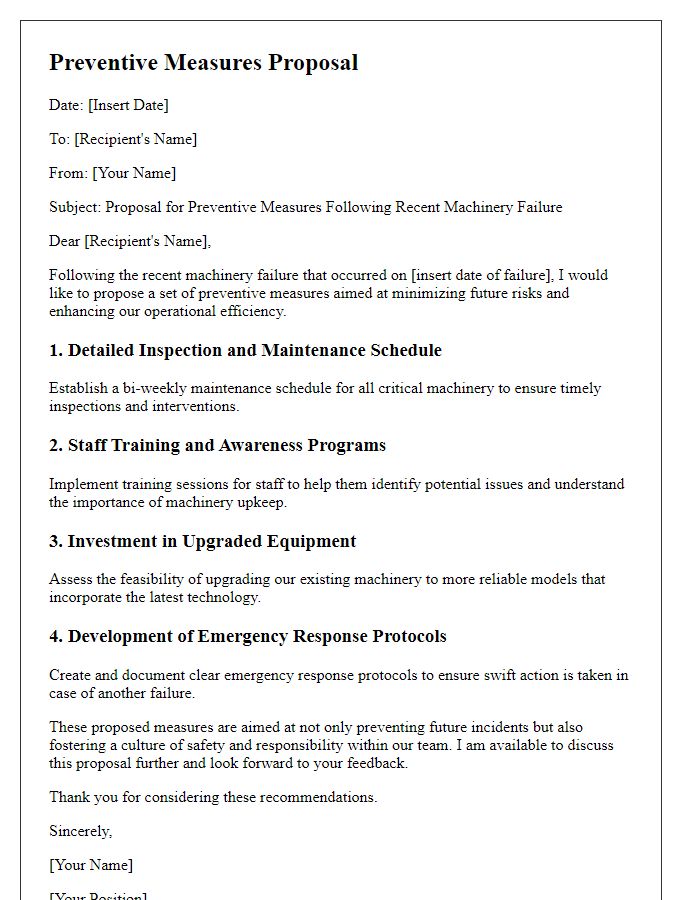

Solution/Next Steps: Outline the proposed corrective measures

Unexpected machinery breakdowns can significantly disrupt operations in manufacturing facilities. Immediate assessment of the malfunctioning equipment is essential, particularly for critical machines like the CNC milling machine (often valued at $100,000). Technicians should conduct a thorough inspection to identify issues, such as worn-out bearings or electrical failures, which could lead to production delays. Implementing a scheduled maintenance plan will help mitigate future breakdowns, including regular lubrication of moving parts and replacement of wear components every 500 hours of operation. Collaborating with suppliers for quick access to replacement parts can streamline repair processes, with expectations set within 24 to 48 hours for crucial components. Training staff on recognizing early signs of mechanical distress, such as unusual noises or vibrations, will enhance response time in future incidents.

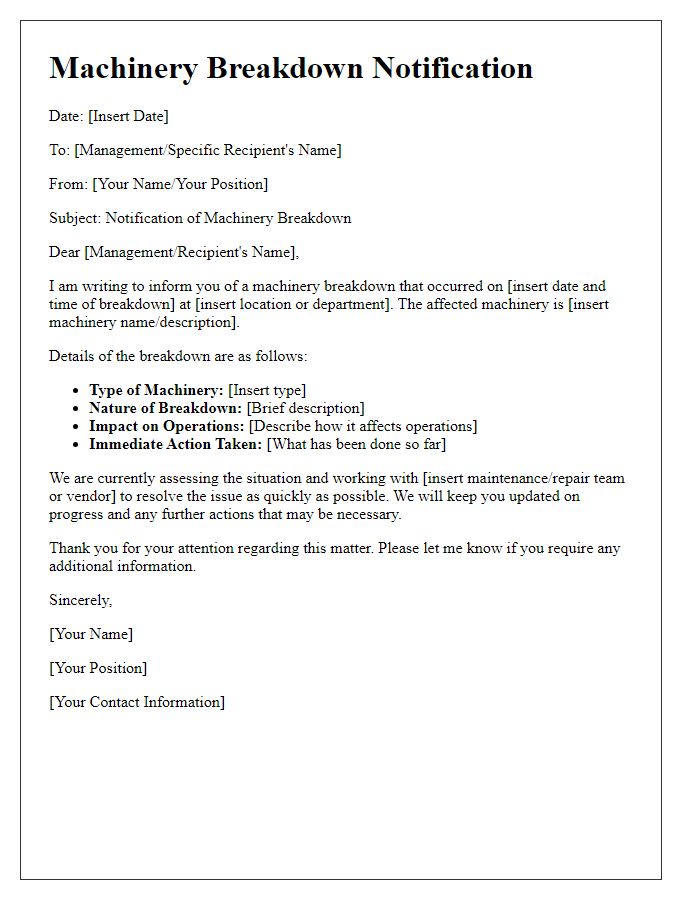

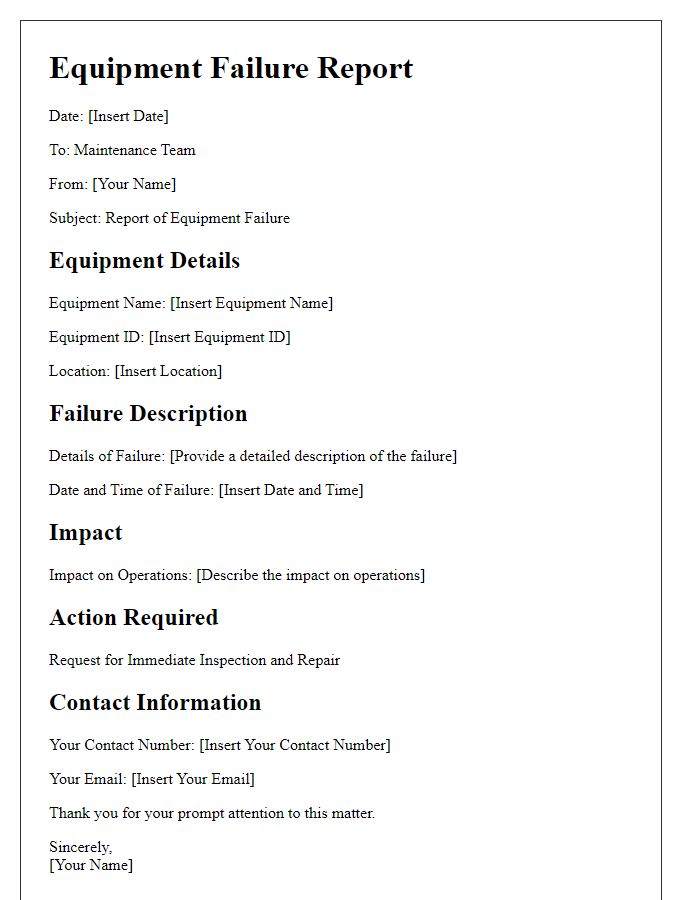

Letter Template For Unexpected Machinery Breakdown Samples

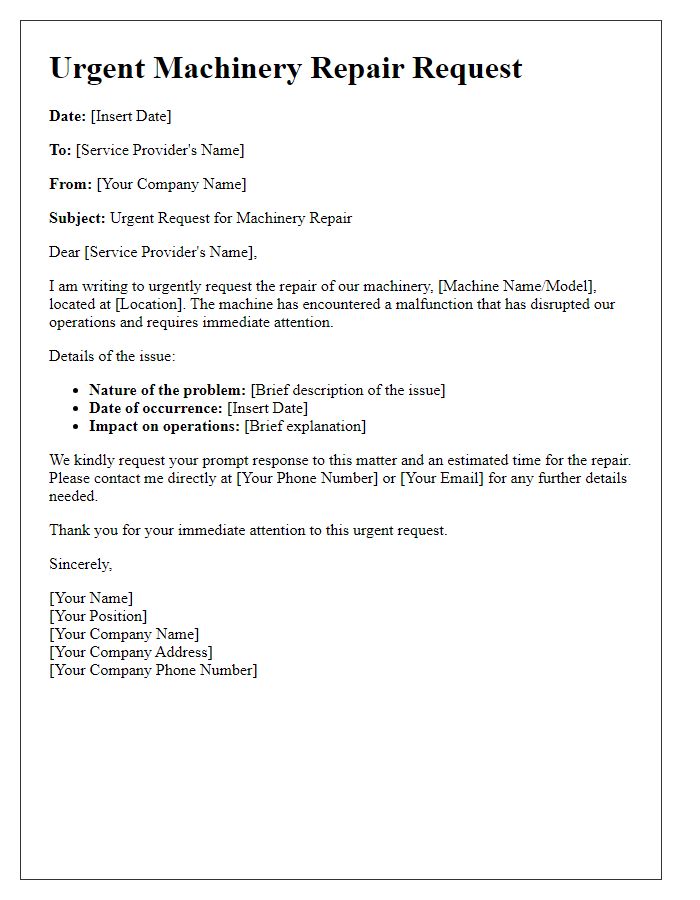

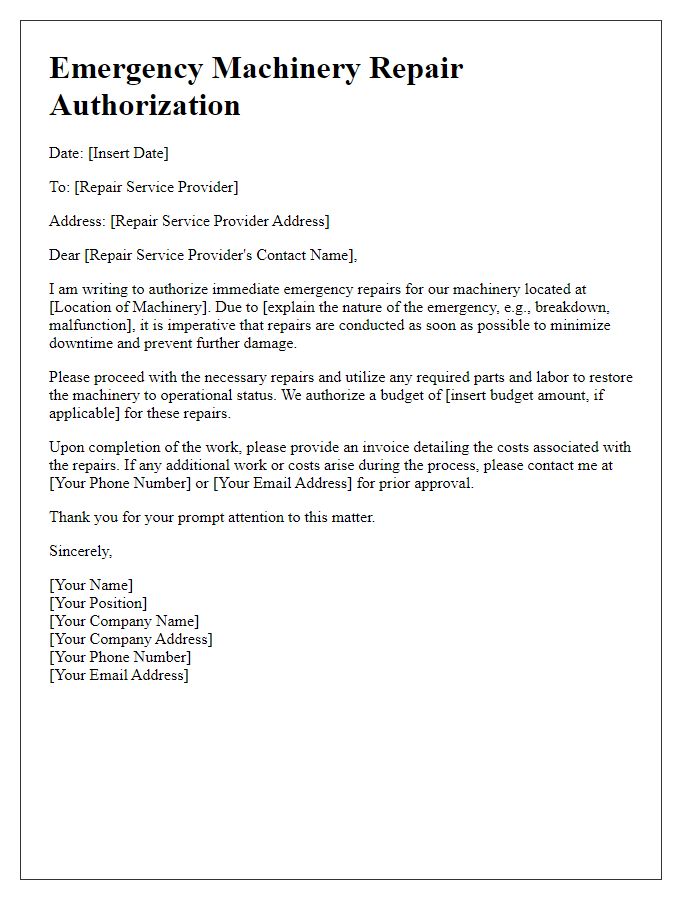

Letter template of urgent machinery repair request to service providers.

Comments