Are you looking to streamline your manufacturing project timeline? Crafting a clear and concise letter can be crucial in keeping all stakeholders informed and aligned. In this article, we'll explore effective templates that make it easy to communicate timelines, milestones, and responsibilities without any hassle. So, let's dive in and discover how you can enhance your project management skills by reading more!

Project Objectives and Scope

The manufacturing project timeline focuses on the efficient production and delivery of high-quality widgets, specifically designed for consumer electronics. The project aims to achieve a 20% increase in production speed by implementing automation technologies such as robotic arms and conveyor systems by Q2 2024. The project scope includes the renovation of the manufacturing facility located in Troy, Michigan, which spans over 100,000 square feet, ensuring compliance with OSHA safety regulations. Additionally, the timeline outlines the integration of lean manufacturing principles to minimize waste and enhance productivity. Key milestones include securing supplier contracts by December 2023 and completing initial pilot runs by February 2024.

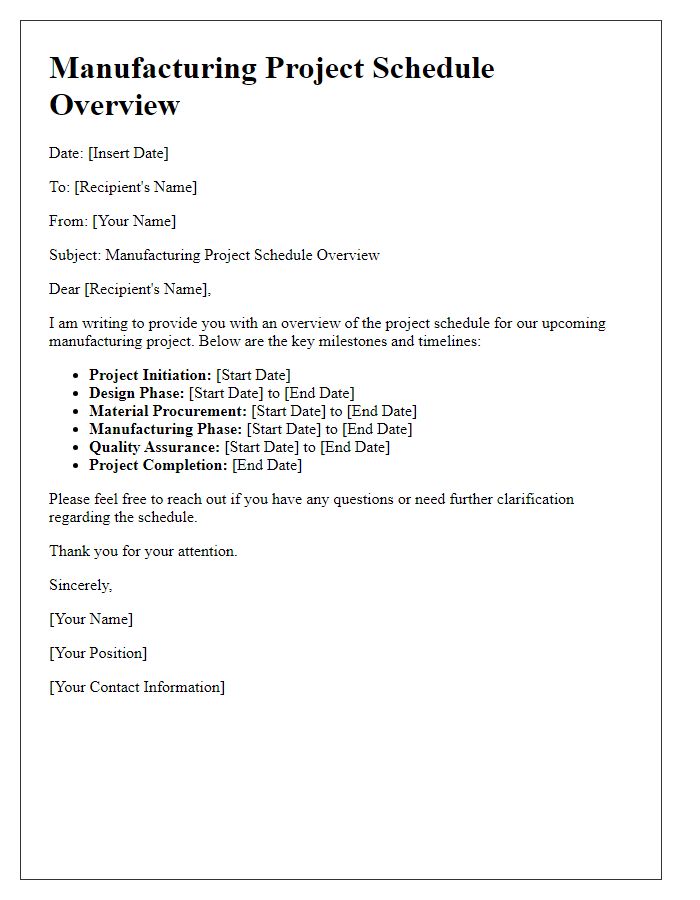

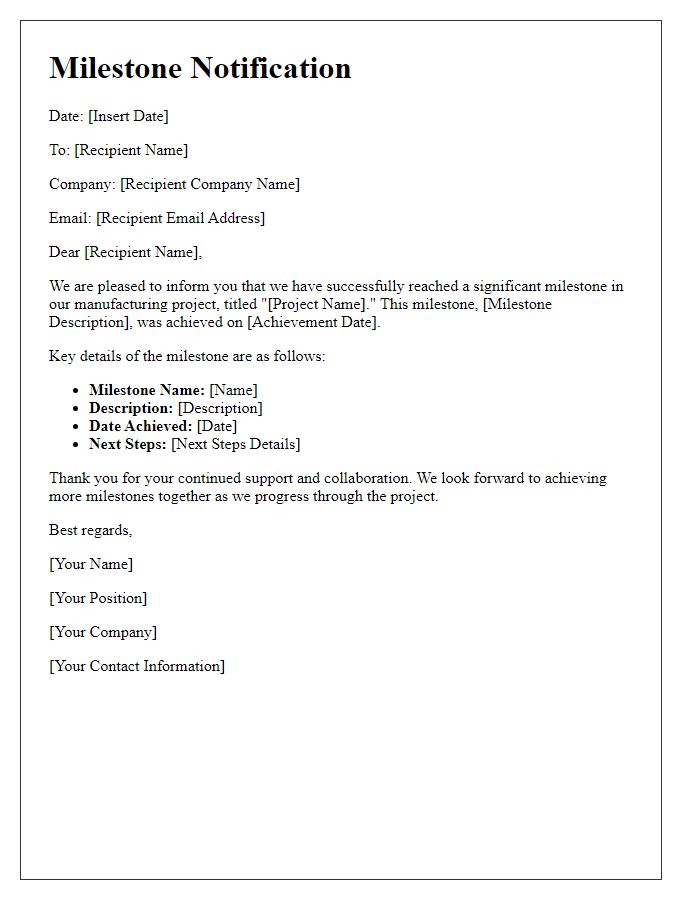

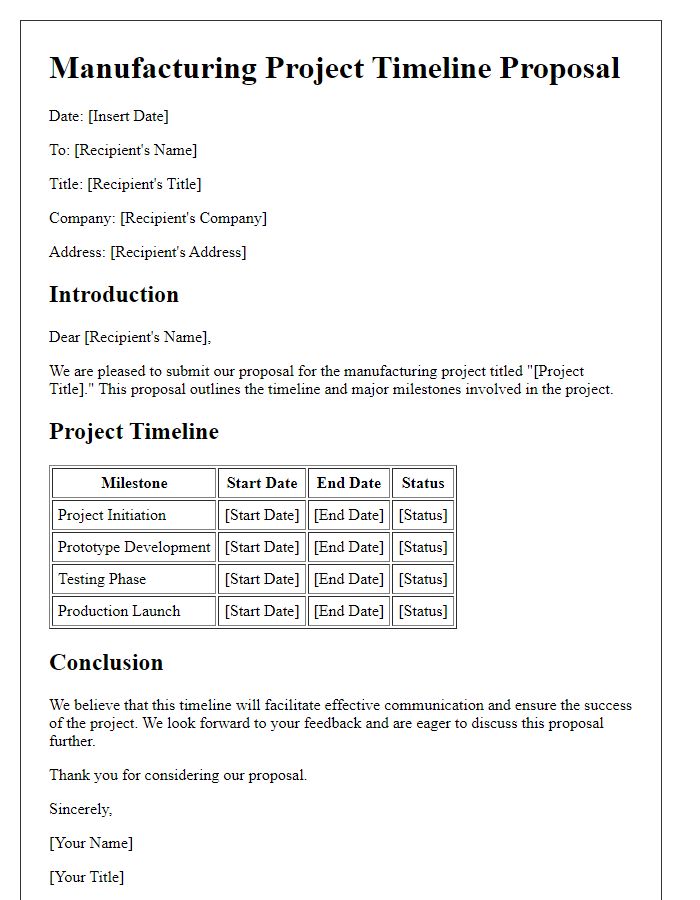

Key Milestones and Deadlines

The manufacturing project timeline is essential for tracking key milestones and deadlines. The planning phase begins with the initial project kickoff meeting, scheduled for July 1, 2023. Following this, the design phase runs from July 15 to August 30, 2023, focusing on creating detailed specifications and prototypes. The procurement stage commences on September 1, 2023, lasting until October 15, 2023, where materials and components, such as high-grade aluminum and advanced microchips, are sourced. The production phase starts on October 20, 2023, and continues until December 15, 2023, involving assembly line setups and quality control processes. Final testing and validation occur from December 20 to January 10, 2024, ensuring all products meet safety standards outlined by ISO 9001. Project completion and delivery milestones are set for January 15, 2024, with post-launch review and assessment scheduled for January 30, 2024.

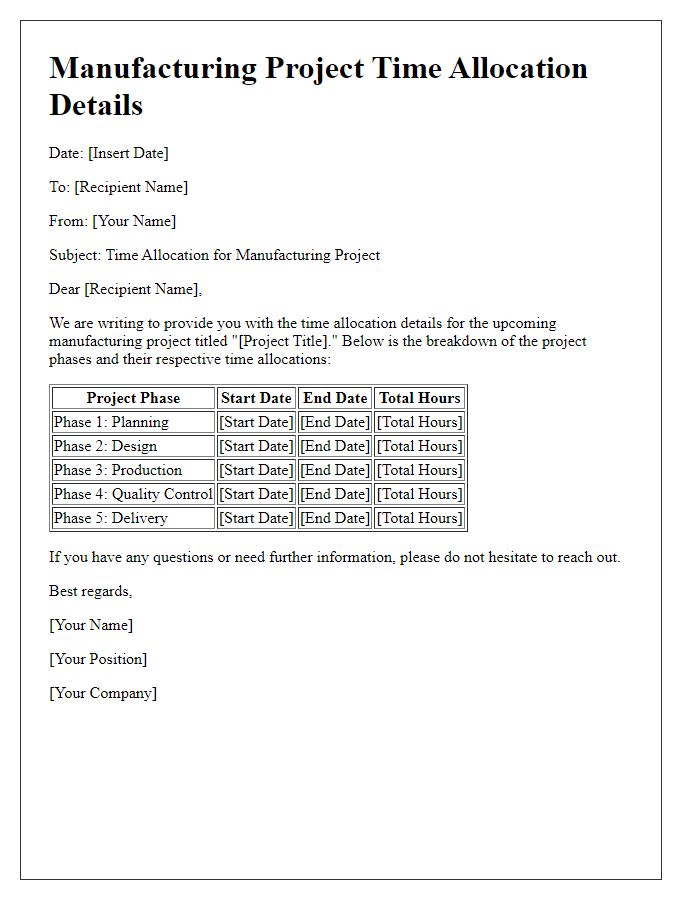

Resource Allocation and Team Responsibilities

Creating a comprehensive timeline for a manufacturing project entails precise resource allocation and well-defined team responsibilities. Each stage of the project, from initial design (February 2023) to final production (June 2023), requires specific resources, including machinery like CNC machines (injection molding, laser cutting) and staff (engineers specializing in materials science, quality control inspectors). Each team member plays a vital role; project managers oversee progress, while assembly line workers execute the manufacturing process. Additionally, procurement teams are tasked with sourcing raw materials, such as steel or polymers, within defined budget constraints, with particular attention to sustainable practices. Effective tracking of milestones ensures that deadlines are met, such as prototype completion by March 15, 2023, and market readiness by July 2023. Collaboration tools, such as Gantt charts, facilitate communication and accountability among different departments.

Risk Management and Contingency Plans

Creating a comprehensive project timeline for manufacturing involves identifying potential risks and implementing contingency plans to mitigate them. Key risks in the manufacturing process include supply chain disruptions, labor shortages, machinery failures, and unforeseen regulatory changes. For example, a supply chain disruption can occur due to geopolitical tensions, affecting the availability of essential raw materials like steel or plastic, which could delay production schedules. A contingency plan might include identifying alternative suppliers or stockpiling materials in advance. Labor shortages can arise from economic downturns or unexpected events like pandemics, highlighting the importance of cross-training employees and maintaining a flexible workforce. Machinery failures, which can lead to significant downtime, necessitate regular maintenance schedules and the availability of spare parts. Finally, staying updated on regulatory changes in manufacturing standards or environmental compliance is crucial to avoid penalties. Regular review meetings should be scheduled to assess risks and update contingency strategies accordingly, ensuring that the project timeline remains on track.

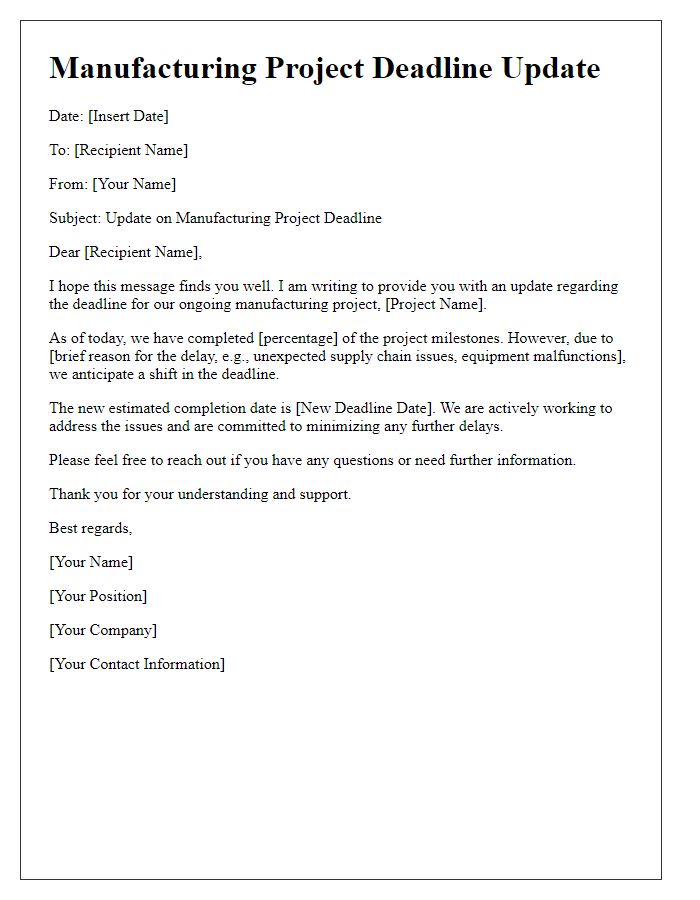

Communication and Reporting Protocols

Effective communication and reporting protocols are crucial for the successful management of manufacturing project timelines, ensuring all stakeholders remain informed and engaged throughout the project's lifecycle. Regular updates are essential, with bi-weekly status meetings scheduled to discuss progress milestones, issues, and action items. Utilizing project management tools, such as Asana or Trello, can enhance visibility, allowing team members to track tasks in real time. Detailed reports, containing quantitative data such as production output rates, equipment downtime percentages, and budget variances, should be distributed at the end of each project phase. Stakeholder feedback sessions will provide valuable insights, fostering collaboration and identifying potential project risks, ultimately leading to the achievement of project goals within stipulated timelines and budget constraints.

Comments