In today's fast-paced industrial world, having a reliable supply of critical spare parts is more important than ever. Unexpected equipment failures can lead to costly downtime, making it essential for businesses to have a strategy for procurement and inventory management. Knowing the right sources and processes for obtaining these vital components can make all the difference in maintaining smooth operations. Ready to dive deeper into how you can enhance your spare parts provision? Keep reading!

Specific Part Identification

Critical spare parts management plays a crucial role in maintaining operational efficiency across industries. Accurate identification of specific parts, such as Bearings (used in machinery), Filters (essential for HVAC systems), or Circuit Boards (integral to electronic devices), ensures timely procurement and minimizes downtime. Each part identification should include unique identifiers like manufacturer part numbers and specifications to facilitate seamless inventory management. Effective tracking of usage and lifecycle events prevents unexpected failures, ensuring that critical machinery, like manufacturing robots or power generation turbines, maintain productivity levels. In industries such as aviation or automotive, where safety and performance are paramount, the precise identification of spare parts is essential to comply with regulations and guarantee reliability in operations.

Urgency and Impact Assessment

Critical spare parts, such as circuit boards and hydraulic pumps, play a vital role in the operational efficiency of industrial machinery. Delays in procurement can lead to significant downtime, increasing operational costs by up to 20%. Assessing urgency is crucial; for example, a failed hydraulic pump in a manufacturing plant can halt production lines, causing a loss of approximately $10,000 per hour. Furthermore, the impact of delayed repairs extends beyond immediate financial losses; it can damage customer relationships and tarnish brand reputation. Timely provisions of these essential components not only ensure seamless operations but also protect the integrity and reliability of service delivery.

Supplier and Manufacturer Details

Critical spare parts provision plays a vital role in maintaining operational efficiency within industries such as manufacturing or energy. Suppliers, like Global Parts Co., based in Houston, Texas, are essential for providing immediate access to essential components. Manufacturers, such as XYZ Manufacturing Ltd., renowned for producing high-quality hydraulic systems, require a steady inventory of specific spare parts, including hydraulic pumps and valves, to minimize downtime during maintenance. Detailed cataloging of these parts, including part numbers and specifications, ensures accurate ordering and timely delivery, preventing disruptions in production schedules. Robust supplier relationships are crucial to ensure that critical parts, like bearings or motors, are readily available, facilitating a seamless operation across various sectors.

Contractual Terms and Conditions

The critical spare parts provision outlines essential aspects of maintenance and supply chain management in industries reliant on machinery and equipment. Timely delivery, such as within 48 hours (standard for many sectors), is crucial for minimizing downtime and ensuring operational efficiency. The contractual agreement typically includes specific terms specifying quantity, quality standards, and compliance with industry regulations. Service Level Agreements (SLAs) often stipulate penalties for non-compliance, aiming to maintain optimal inventory levels at locations like manufacturing plants or logistics hubs. Additionally, pricing structures, warranties, and after-sales support are vital components ensuring long-term partnerships between suppliers and customers. Proper notification procedures for any changes in supply or availability also play an essential role in effective communication and planning.

Delivery and Logistics Arrangements

Timely delivery of critical spare parts, such as automotive components or industrial machinery parts, is essential for maintaining operational efficiency in various industries, notably manufacturing and transportation. Coordination with logistics providers plays a vital role, ensuring parts are transported securely and swiftly from warehouses or suppliers to end-users. For example, utilizing air freight for urgent shipments can reduce transit times to under 24 hours, while sea freight, although cost-effective, may extend delivery times to several weeks. Proper tracking systems should be implemented for real-time updates, enhancing transparency in delivery status. Addressing customs clearance procedures can prevent unnecessary delays, particularly for international shipments. Furthermore, implementing a just-in-time inventory strategy can minimize storage costs while ensuring that critical spare parts are readily available when needed, reducing the risk of production downtime.

Letter Template For Critical Spare Parts Provision Samples

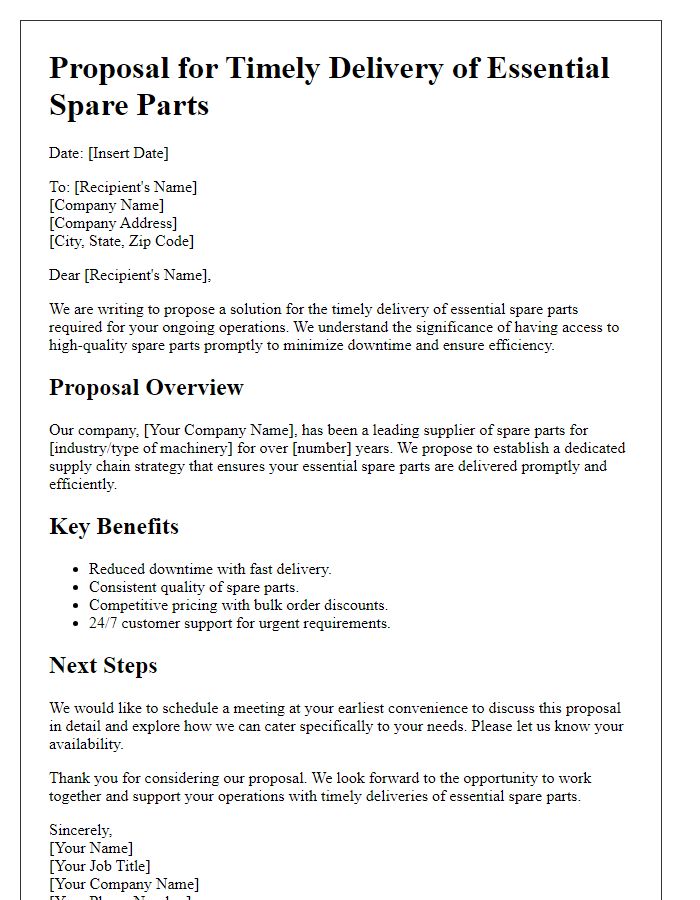

Letter template of proposal for timely delivery of essential spare parts.

Comments