Keeping our equipment in top-notch condition is crucial for smooth operations and efficiency. Regular maintenance not only extends the life of our machinery but also prevents unexpected breakdowns that can hinder productivity. Let's explore the importance of sticking to a maintenance schedule and how it can benefit your workplace. Ready to learn more about optimizing your equipment maintenance?

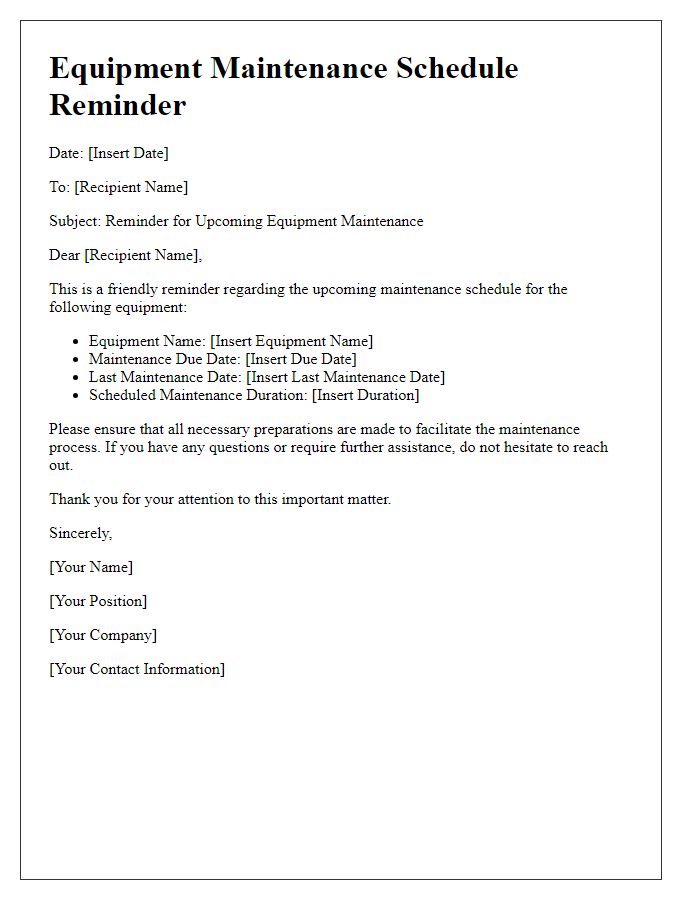

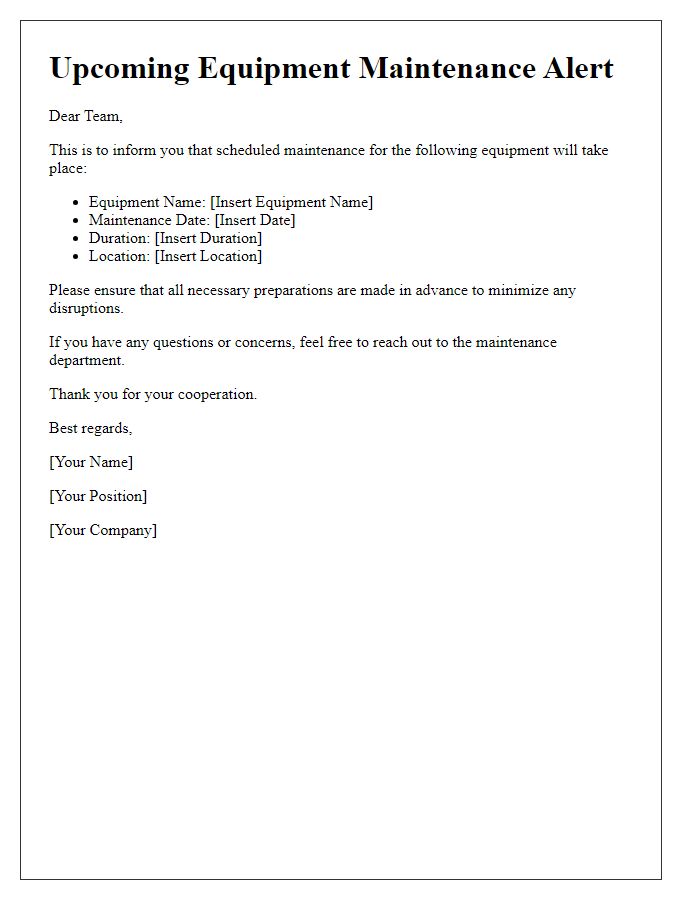

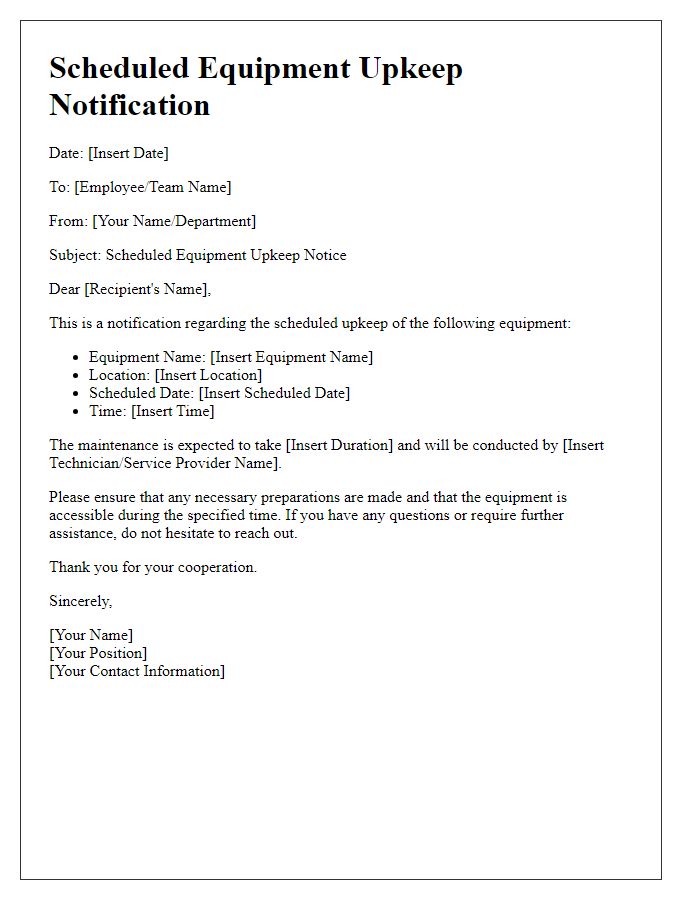

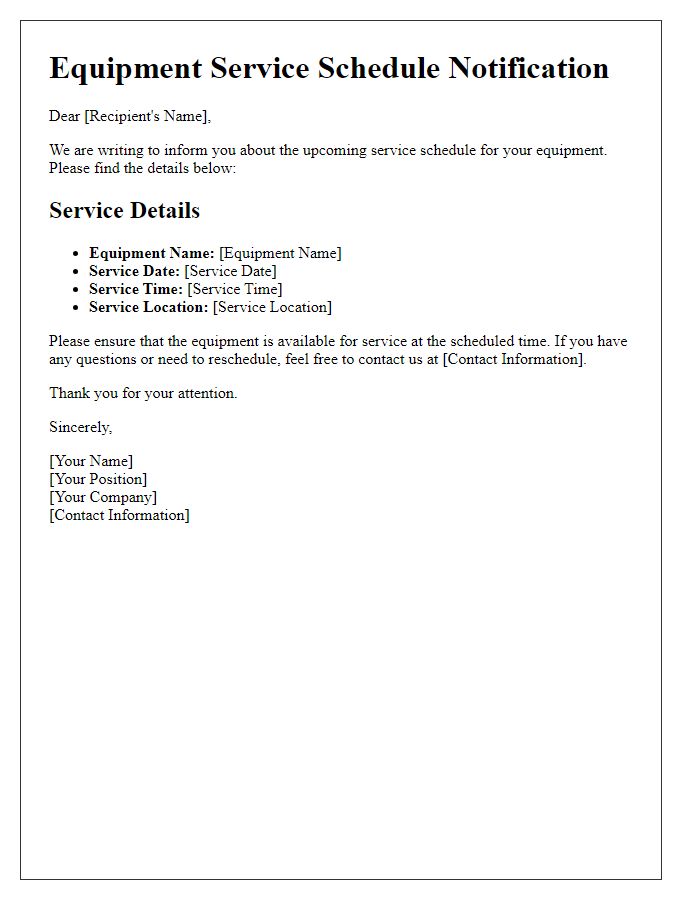

Recipient Details

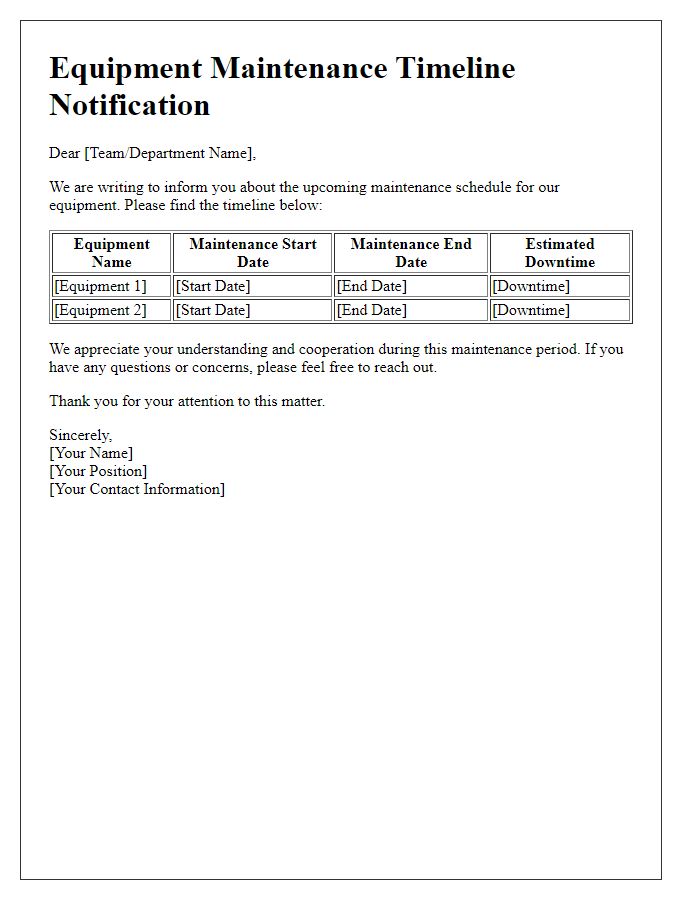

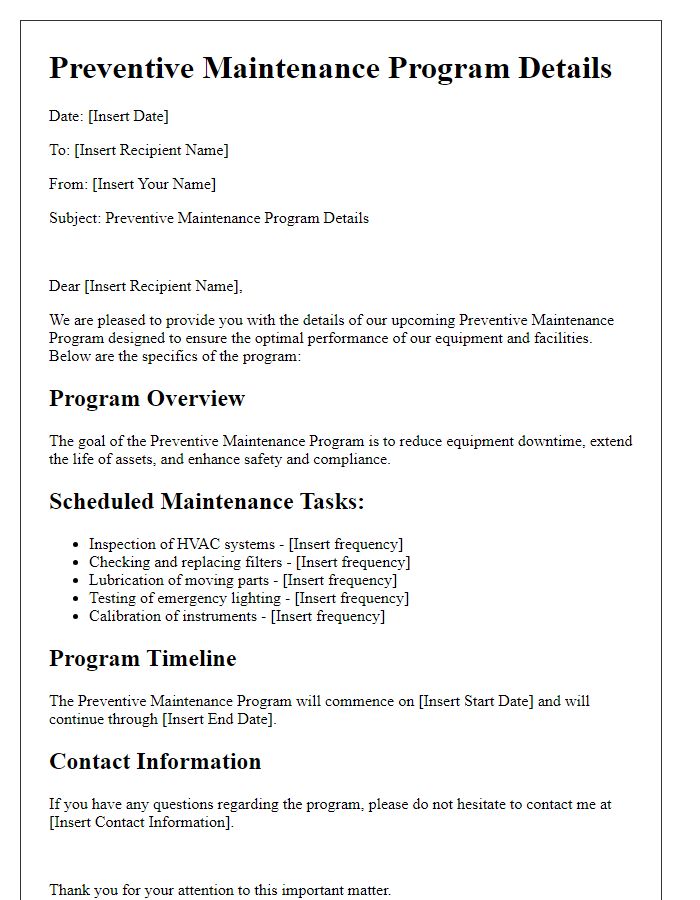

The equipment maintenance schedule notification is essential for ensuring optimal performance of machinery. Scheduled maintenance, such as inspections and service checks, typically occurs every quarter (every three months). Equipment models, like the Caterpillar 320D excavator or the John Deere 5075E tractor, require specific attention to components such as hydraulic systems and engine filters. Location, like the maintenance facility in Dallas, Texas, provides access to experienced technicians. Notifications should include detailed instructions regarding preparation steps, such as removing obstacles or providing access to power sources. Prompt communication allows for downtime planning, minimizing disruptions to operations in industries such as construction, agriculture, or manufacturing.

Subject Line

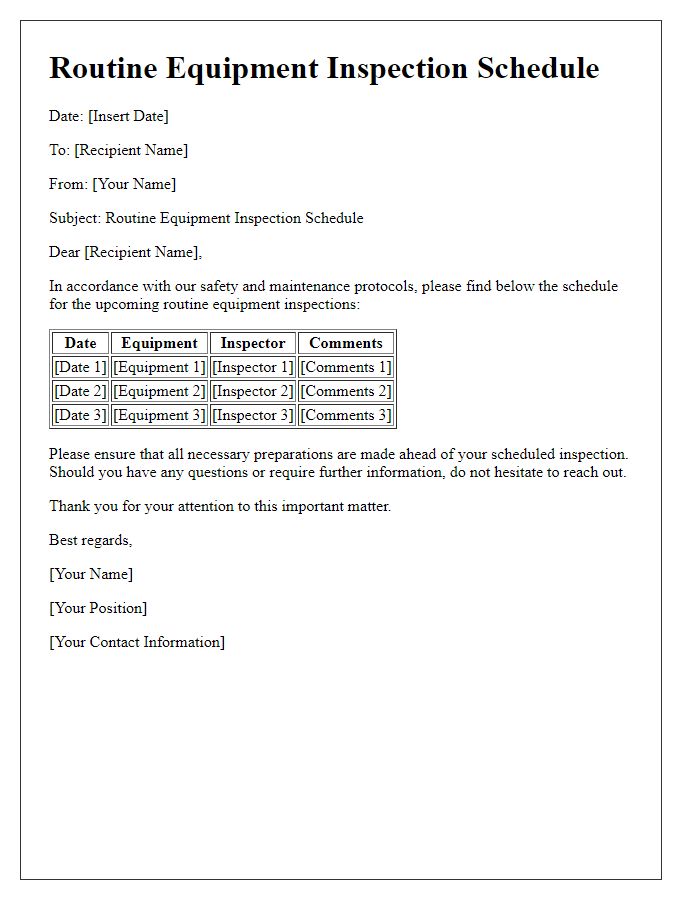

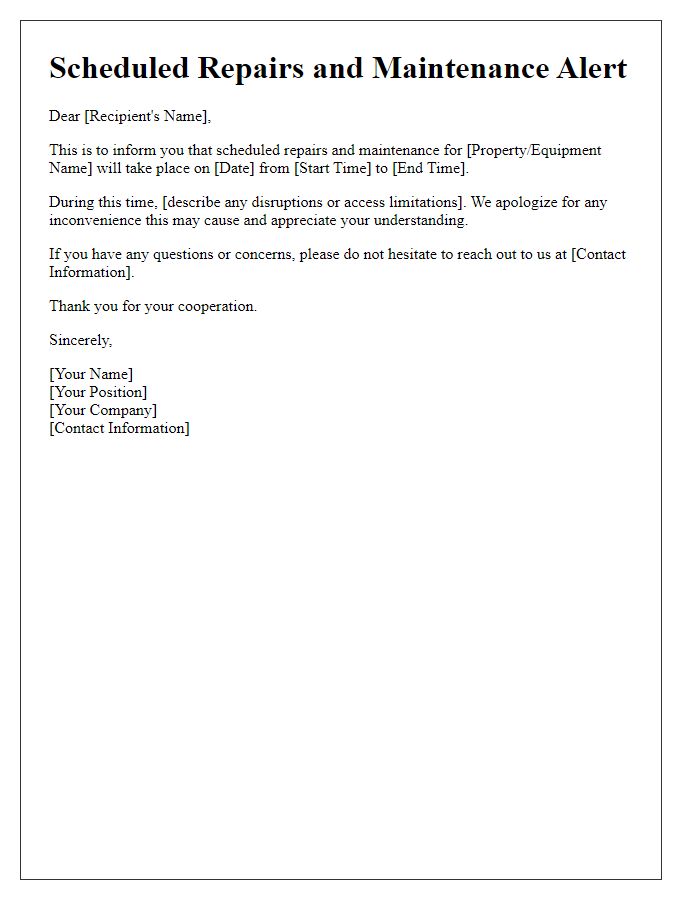

Regular equipment maintenance is crucial for ensuring optimal performance and longevity, especially in industrial settings such as manufacturing plants or construction sites. Scheduled checks, typically every three to six months, help identify potential issues, including wear and tear on machinery and the aging of critical parts like hydraulic systems and electrical components. Proper maintenance not only minimizes unexpected downtime but also enhances safety protocols, reducing the risk of accidents associated with faulty equipment. In addition, keeping detailed maintenance logs can assist in tracking equipment history, improving reliability, and making informed decisions about replacements or upgrades.

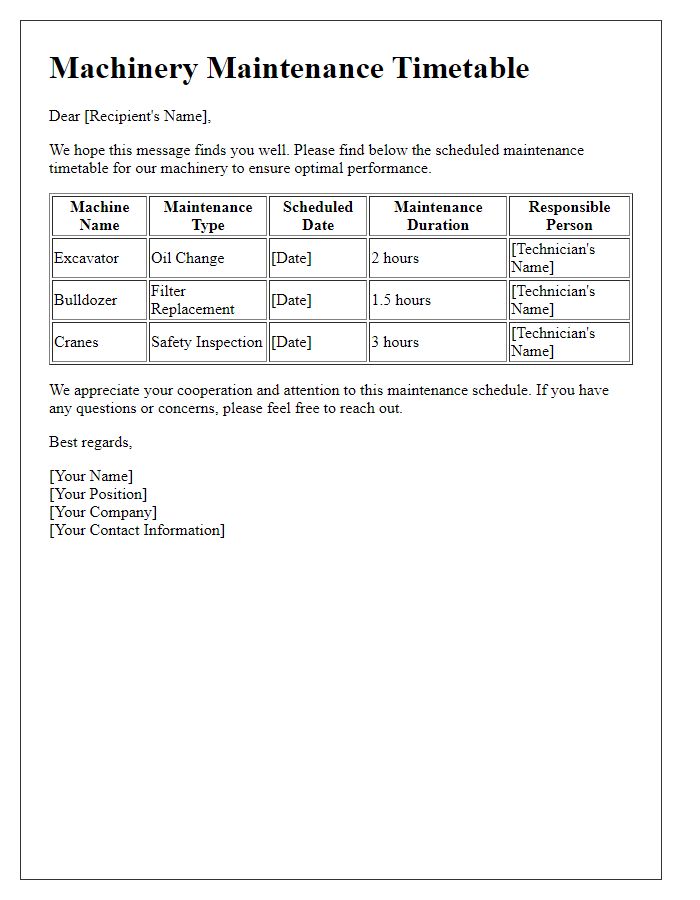

Maintenance Schedule Date and Time

The maintenance schedule for the advanced manufacturing equipment, including CNC machines and 3D printers, is set for October 15, 2023, from 10 AM to 4 PM at the main production facility in Springfield, Illinois. This essential maintenance will involve inspecting critical components such as motors, belts, and sensors to ensure optimal performance and prevent unexpected downtime. Technicians will perform comprehensive checks on hydraulic systems and software calibrations. All operators and staff are advised to secure their workspaces and refrain from using the equipment during this period to allow for uninterrupted servicing.

Equipment Details

The maintenance schedule notification for equipment, specifically the hydraulic press used in manufacturing, is crucial for operational efficiency. This hydraulic press, model HP-2000, requires routine inspections every 500 operational hours or every three months, whichever comes first. Maintenance activities include fluid level checks, filter replacements, and hydraulic system evaluations. It is essential to report any anomalies, such as unusual noises or decreased pressure readings, to the maintenance team immediately. Scheduled maintenance will occur on the first Monday of each month in the designated workshop area, ensuring minimal disruption to production processes. Additionally, operators must document all maintenance activities in the maintenance logbook for record-keeping and compliance with industry safety standards.

Contact Information

Scheduled maintenance is vital for equipment longevity and performance. Regular inspections can prevent costly breakdowns and ensure safety. For example, commercial kitchen equipment (ovens, refrigerators) requires monthly checks to guarantee regulatory compliance and efficient operation. Machinery in manufacturing plants such as CNC (Computer Numerical Control) machines should receive maintenance every 500 operating hours to avoid production delays. Maintenance records should document all services performed, including parts replaced and technician notes. Contact information for maintenance providers must remain accessible, allowing quick responses to repairs or consultations, thereby minimizing downtime and enhancing productivity.

Comments