Are you grappling with the complexities of regional logistics planning? You're not alone! Many organizations face the same challenges as they strive to optimize their supply chains and improve efficiency. In this article, we'll explore effective strategies and useful templates to help streamline your logistics processes, so keep reading to unlock valuable insights!

Clear Objective Statement

A well-defined objective statement is crucial for regional logistics planning, particularly for optimizing supply chain efficiency in areas such as the Southeast United States. This objective should focus on reducing transportation costs by 15% within the next fiscal year while ensuring timely deliveries to 50 major retail distribution centers across five states, including Georgia and North Carolina. Implementing advanced tracking software could enhance visibility and efficiency, maximizing resource utilization. Additionally, utilizing environmentally-friendly transport options can align with sustainability goals and regulations from the Environmental Protection Agency, offering long-term benefits and compliance with federal standards.

Key Stakeholders Identification

In regional logistics planning, identifying key stakeholders plays an integral role in ensuring seamless supply chain operations. Major entities include local government agencies, such as transportation departments that regulate road usage and infrastructure. Private sector stakeholders, including logistics companies like FedEx and UPS, manage transportation and delivery services, offering insights into operational efficiencies. Retailers, such as Walmart and Target, influence demand forecasting and distribution strategies as they rely heavily on timely deliveries. Local businesses and suppliers contribute to regional economic dynamics, essential for collaborative planning. Community organizations also play a vital role as they advocate for public interests, ensuring that logistics strategies align with environmental and social goals. Understanding the influence and needs of these stakeholders is crucial for developing effective regional logistics plans that foster collaboration and drive success in supply chain initiatives.

Resource Allocation Details

Regional logistics planning requires careful resource allocation to optimize supply chain efficiency. Essential components include transportation fleets, warehouse capacities, and inventory levels. Transportation fleets, such as trucks and freight trains, must be selected based on regional demand forecasts, which can vary significantly, sometimes by up to 30% during peak seasons. Warehouse capacities, particularly in strategic locations like Atlanta, Georgia, and Chicago, Illinois, must also be assessed, with average storage space ranging from 50,000 to 200,000 square feet per facility. Inventory levels should align with just-in-time (JIT) practices to minimize excess stock, which can incur costs up to 25% of product value annually. Utilizing data analytics and metrics, such as shipment turnover ratios and order fulfillment rates, can further enhance decision-making and streamline logistics processes across the region.

Timeline and Milestones

Regional logistics planning involves strategic coordination of transportation and warehousing activities across multiple locations to optimize supply chain efficiency. Key milestones in this process typically include a comprehensive assessment of regional demand forecasts, which analyzes factors such as seasonal trends and market growth (projected at 5% annually in the Northeast region). Following this evaluation, developing a transportation network strategy becomes essential, focusing on the selection of optimal distribution centers (like those located within a 100-mile radius of major urban centers such as Philadelphia) to reduce delivery times and costs. The third milestone involves implementing technology solutions for tracking inventory flows, including a comprehensive ERP system that can automate order processing and facilitate real-time data analysis. Final milestones revolve around establishing key performance indicators (KPIs) to measure success post-implementation, such as reducing average delivery times to under 48 hours, ensuring that customers receive their orders swiftly and efficiently. Regular review meetings are scheduled to ensure targets remain aligned with evolving market demands.

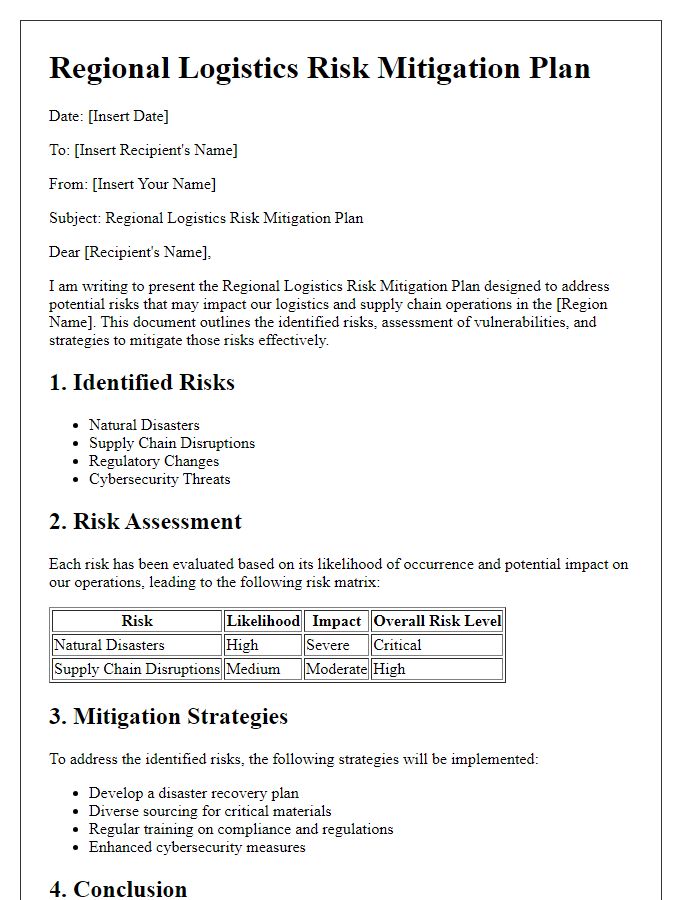

Risk Management Strategies

Regional logistics planning involves identifying and mitigating potential risks that could disrupt supply chains in specific geographic areas. Natural disasters, such as hurricanes in the Gulf Coast or wildfires in California, pose significant threats to logistics operations, often leading to delays in transportation and increased costs. Infrastructure failures, including bridge collapses or road closures in urban centers like New York City, can further complicate delivery schedules. Additionally, geopolitical issues, such as trade disputes affecting ports in Los Angeles, may create uncertainties in the supply chain. Implementing risk management strategies, such as diversifying transportation routes and establishing backup supplier agreements, can enhance resilience and ensure continuity of operations during crises. Regular risk assessments and contingency planning are essential to adapt to changing conditions effectively.

Comments