Are you looking to streamline your logistics operations and ensure everything runs smoothly? Crafting a solid standard operating procedure (SOP) is essential for consistency and efficiency in your logistics processes. In this article, we'll break down the key components of a logistics SOP template, making it easier for your team to follow best practices every step of the way. So, let's dive in and explore how you can enhance your logistics framework for better results!

Purpose and Objective

The purpose of the Logistics Standard Operating Procedure (SOP) is to establish clear and consistent guidelines for managing the flow of goods and services within an organization. This SOP aims to enhance efficiency by outlining specific processes for inventory management, order fulfillment, transportation logistics, and supply chain coordination. The objective is to ensure that all logistics operations meet regulatory compliance standards, improve operational effectiveness, and minimize costs associated with delays or mismanagement. By implementing this SOP, the organization seeks to optimize resource utilization, streamline communication among logistics personnel, and maintain high levels of customer satisfaction through timely delivery and accurate order processing.

Scope and Applicability

Logistics standard operating procedures (SOP) establish essential guidelines to enhance efficiency in transportation and distribution activities within organizations. This SOP applies to all logistics personnel across various departments, including warehouse management, inventory control, and shipping operations. Key processes covered include freight management, inventory tracking systems, and vendor coordination, aiming for adherence to local regulations and industry standards. Additionally, this document serves as a foundational reference for training approximately 150 staff members in best practices, ensuring compliance with safety protocols and maximizing operational effectiveness. All stakeholders involved in logistics processes, from entry-level employees to senior managers, must understand and implement these procedures to support overall business objectives.

Roles and Responsibilities

In a logistics standard operating procedure (SOP), the roles and responsibilities document outlines essential tasks for various team members involved in supply chain operations. Warehouse managers oversee inventory management systems, ensuring accurate tracking of goods, while logistics coordinators manage transportation schedules and maintain communication with carriers. Chain operators monitor shipments, confirming timely delivery and adherence to safety regulations. Quality assurance personnel conduct inspections at distribution centers, guaranteeing compliance with company standards and regulatory guidelines. Additionally, customer service representatives handle inquiries, providing clients with updates on shipment status and resolving issues promptly. Each role contributes to the seamless flow of goods from suppliers to end customers, emphasizing the importance of clear communication and coordination among team members.

Process Workflow

Efficient logistics standard operating procedures (SOP) are critical for optimizing supply chain management. The process workflow outlines key stages, including order processing, inventory management, and transportation planning. Order processing involves receiving customer requests, confirming documentation within established timelines (usually 24 hours), and preparing shipments. Inventory management requires software systems (like RFID or barcode scanning) to monitor stock levels across warehouses, ensuring timely replenishment and reducing excess inventory by approximately 15% annually. Transportation planning encompasses route optimization using GPS technology to minimize delivery times and costs, aiming for a 98% on-time delivery rate. Continuous improvement measures include regular audits and assessments performed quarterly to identify inefficiencies and implement corrective actions, thereby enhancing overall operational performance.

Compliance and Reporting

Logistics standard operating procedures (SOP) for compliance and reporting are essential for maintaining regulatory standards in supply chain management. These procedures encompass critical elements such as adherence to Title 49 of the Code of Federal Regulations (CFR) governing transportation safety and environmental regulations. A detailed reporting process is established to monitor shipment metrics, including on-time delivery rates, which can be a variation of 10-15% in busy seasons. Furthermore, audits are conducted quarterly to evaluate compliance with internal policies and external regulations, ensuring that all logistics operations align with international standards like ISO 9001. Staff training programs are implemented quarterly, with over 90% participation to reinforce knowledge of compliance requirements and reporting protocols. The collection and analysis of data from tracking systems contribute to accurate reporting, with reports generated bi-weekly for executive review and strategic decision-making.

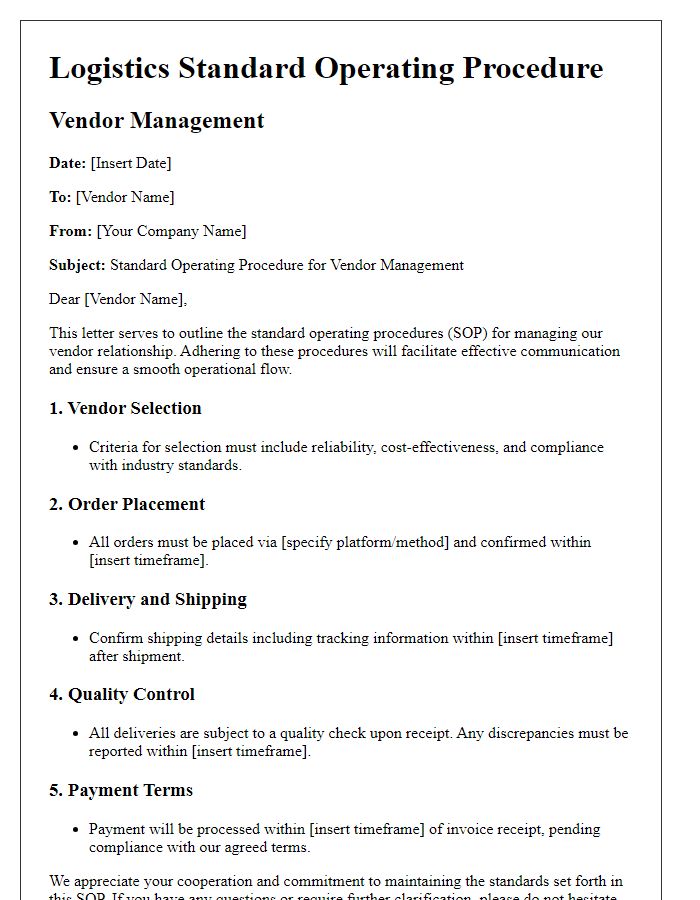

Letter Template For Logistics Standard Operating Procedure Samples

Letter template of logistics standard operating procedure for warehouse management.

Letter template of logistics standard operating procedure for transportation coordination.

Letter template of logistics standard operating procedure for inventory control.

Letter template of logistics standard operating procedure for supply chain compliance.

Letter template of logistics standard operating procedure for quality assurance.

Letter template of logistics standard operating procedure for shipment tracking.

Letter template of logistics standard operating procedure for freight management.

Letter template of logistics standard operating procedure for customs clearance.

Letter template of logistics standard operating procedure for emergency response.

Comments