Have you ever had a moment where a logistics invoice just doesn't add up? Perhaps you've noticed a discrepancy that leaves you scratching your head, trying to figure out what went wrong. Don't worry; you're not alone in this logistical labyrinth! Join me as we delve deeper into understanding how to address these common issues effectively and ensure smooth sailing in your operationsâread on to discover more!

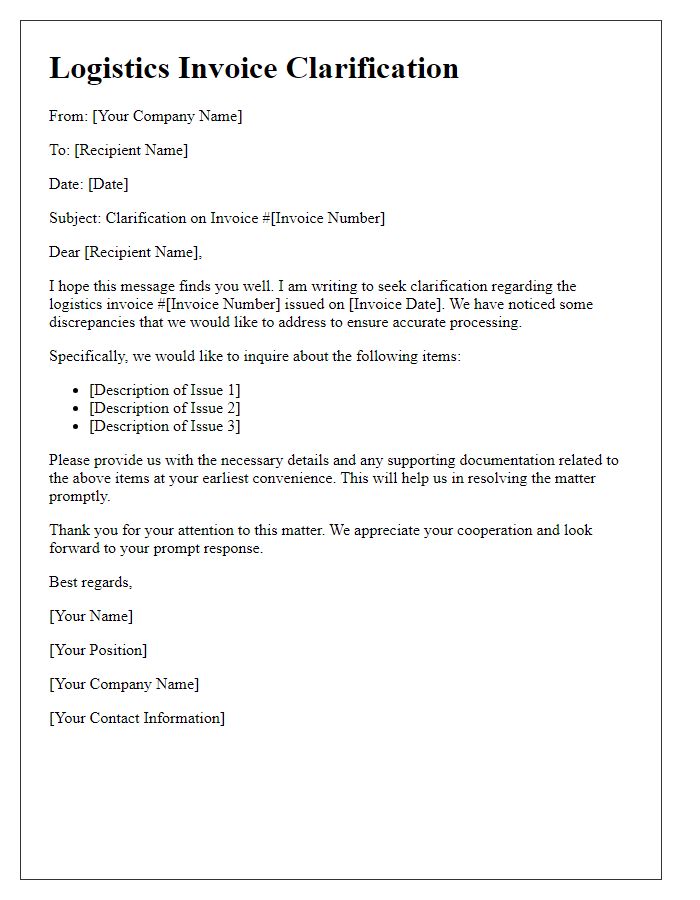

Clear identification of invoice and shipment details.

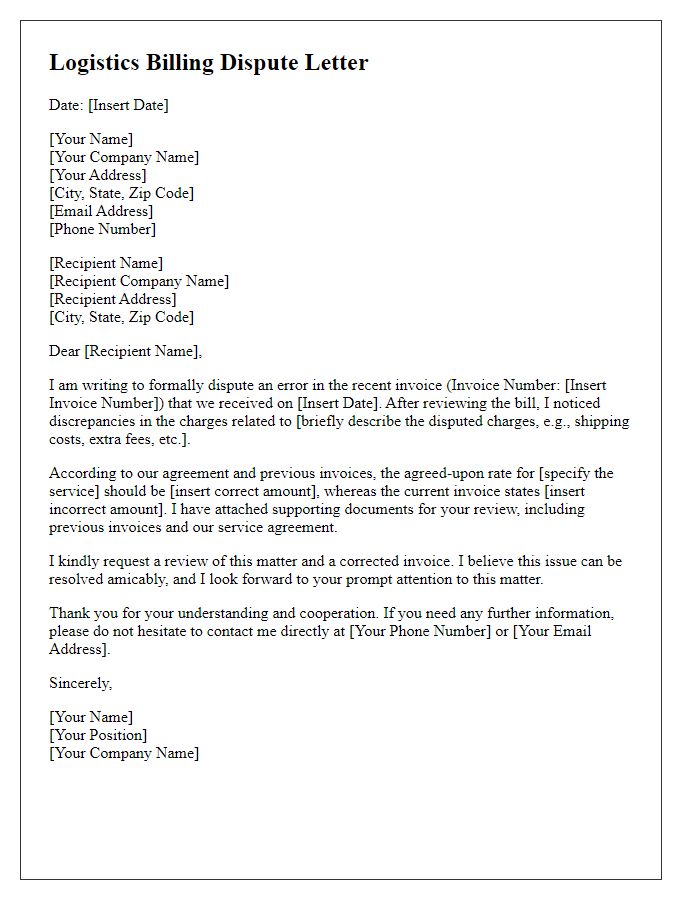

A logistics invoice discrepancy can create significant challenges for financial reconciliation. Precise identification of invoice numbers (example: INV-123456) and shipment details (known as Bill of Lading number, such as BOL-789012) is crucial for efficient resolution. Shipment dates (for instance, March 15, 2023) must align with invoice issuance dates (like April 5, 2023) to confirm accuracy. Additionally, details regarding the sender (company name, address) and receiver (destination, address) should be clearly stated to avoid confusion. Product descriptions (Sourcing of electronics, bulk packaging), quantities (like 150 units), and per-unit costs (for example, $10 each) are essential to validate discrepancies. Any adjustments or corrections to the billed amount should reference the specific terms of the agreed freight (such as agreed rates, accessorial charges). Accurate documentation ensures timely resolutions and smooth financial operations.

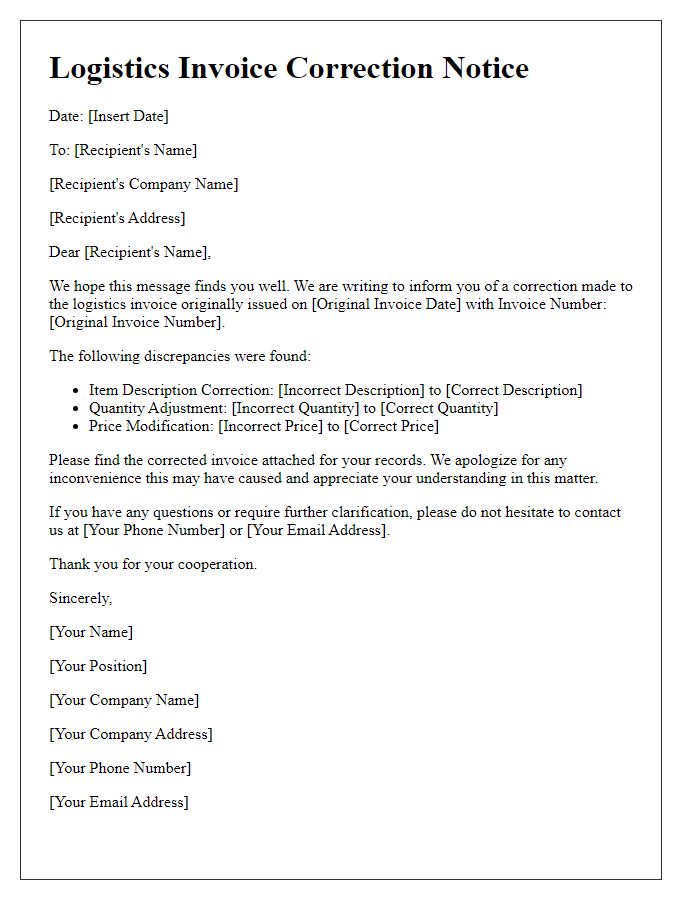

Explicit description of the discrepancy.

The logistics invoice discrepancy identified involves a significant deviation in the billed quantity of products, specifically 500 units of item code ABC123, as per the shipping manifest dated March 1, 2023, from Warehouse A in Chicago, Illinois. The invoice amounts to a total of $5,000, reflecting an overcharge of $1,000 compared to the agreed price set in the contract from January 15, 2023. Delivery receipt number DR4567 confirms that only 400 units were actually received. Furthermore, discrepancies in the shipping weights were noted, where the invoice listed a total weight of 2,000 pounds, while the actual shipping weight verified via the logistics tracking system was only 1,600 pounds. This inconsistency in both quantity and weight needs immediate attention for accurate financial reconciliation and to uphold contractual obligations.

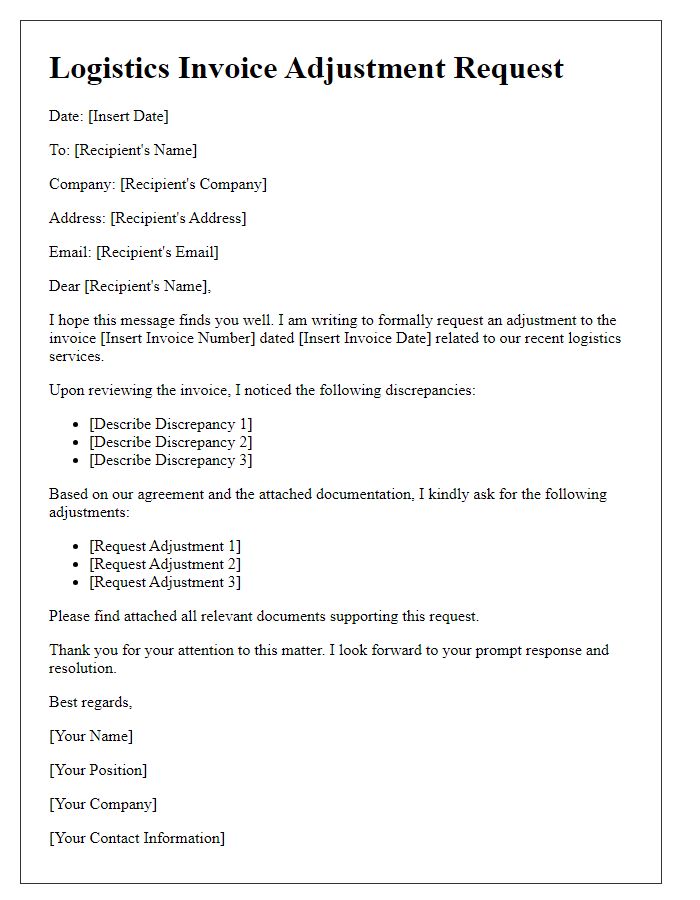

Requested corrective actions or adjustments.

A logistics invoice discrepancy often arises when the billed amount does not align with the agreed contract terms or the actual services rendered. Discrepancies can involve various elements, such as incorrect shipment quantities (for instance, 100 units shipped versus 120 units invoiced), erroneous freight rates (e.g., $500 charged instead of the agreed $450), or missing accessorial charges (like loading fees). Immediate corrective actions are crucial; they include issuing credit notes, adjusting future invoices accordingly, or providing documentation to clarify the discrepancies (such as shipping manifests or signed delivery receipts). Prompt resolution ensures smoother operations and maintains healthy business relationships between shipping companies and clients.

Supporting documentation or evidence.

In logistics operations, invoice discrepancies often arise due to various factors affecting shipments, such as miscounts or discrepancies in service fees. Supporting documentation, including proof of delivery receipts, order confirmations, or weight tickets, plays a crucial role in resolving these issues. Detailed records, such as the delivery date (e.g., June 15, 2023) and the specific carrier name (e.g., FedEx), provide clarity in discussions. Additional evidence, like photographs of the received goods showing condition and quantity, offers tangible support. Moreover, any correspondence exchanged with the logistics provider, including emails and service agreements, can serve as critical elements in addressing the invoice discrepancies effectively.

Contact information for follow-up and resolution.

A logistics invoice discrepancy often arises from mismatched figures related to transport costs, weight measurements, or item quantities during shipping processes. Companies like FedEx or UPS handle such volume discrepancies frequently, given their vast networks. Specific details, such as invoice number or tracking number, can help streamline the resolution process. Including precise contact information, including phone numbers and email addresses of key personnel in the billing department, can expedite follow-up. Documenting discrepancies with shipping dates and locations, such as shipping from Los Angeles to New York, ensures clear communication and aids in rectifying issues promptly.

Comments