In today's fast-paced world, supply chain disruptions can impact businesses in unexpected ways. Whether it's a natural disaster, geopolitical tensions, or unforeseen demand spikes, understanding these challenges is crucial for maintaining smooth operations. By keeping ourselves informed and prepared, we can navigate these turbulent waters more effectively. Dive into this article to discover best practices for managing supply chain disruptions and how to keep your operations resilient!

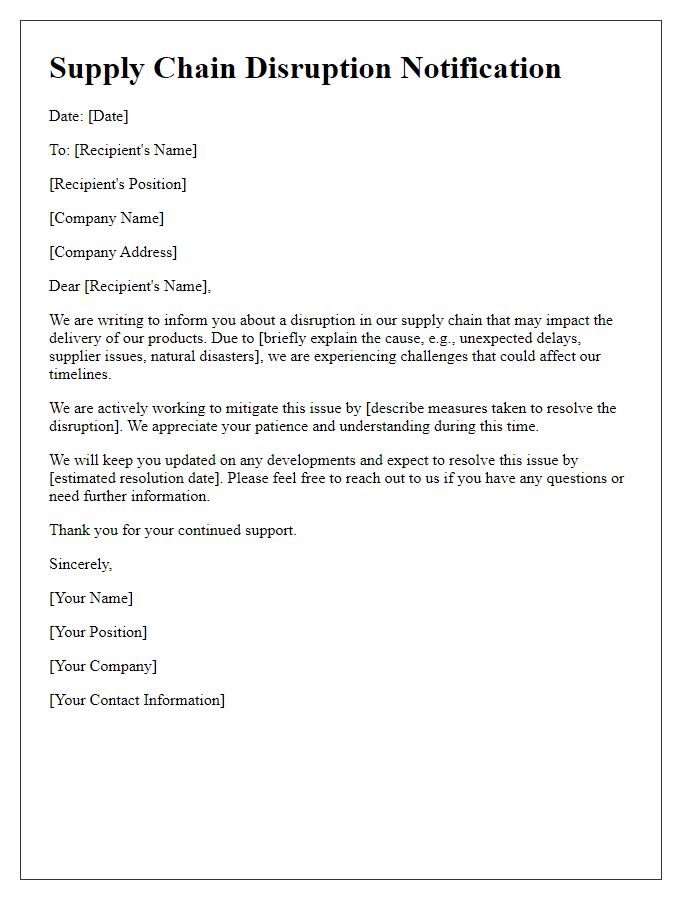

Clear Identification of Disruption

Recent supply chain disruptions have significantly impacted delivery schedules for essential goods. Natural disasters, such as Hurricane Ian affecting Florida's shipping ports in September 2022, led to unexpected delays. Additionally, ongoing global semiconductor shortages continue to hinder automotive production, with industry leaders reporting a 30% decline in output. Transportation bottlenecks, particularly in major cargo hubs like Los Angeles, exacerbate these issues, causing ripple effects across various sectors. As a result, affected companies face increased lead times, inventory shortages, and challenges in fulfilling customer orders on time.

Impact Analysis on Delivery or Production

Supply chain disruptions can significantly impact delivery schedules and production processes across various industries. Recent events, such as the COVID-19 pandemic, have highlighted vulnerabilities in global supply networks, affecting materials sourcing and logistics. For instance, semiconductor shortages in 2021 led to delays in the automotive industry, with companies like Ford reporting a reduction in vehicle production by 40%. Transportation bottlenecks at major ports, such as the Port of Los Angeles, have resulted in prolonged shipping times, impacting retail inventory levels and customer satisfaction. Furthermore, natural disasters, such as hurricanes, can severely disrupt operations, leading to temporary shutdowns in affected manufacturing facilities, particularly in regions like Louisiana, which houses key petrochemical plants. Understanding these disruptions and proactively addressing them is crucial for maintaining operational efficiency and customer trust.

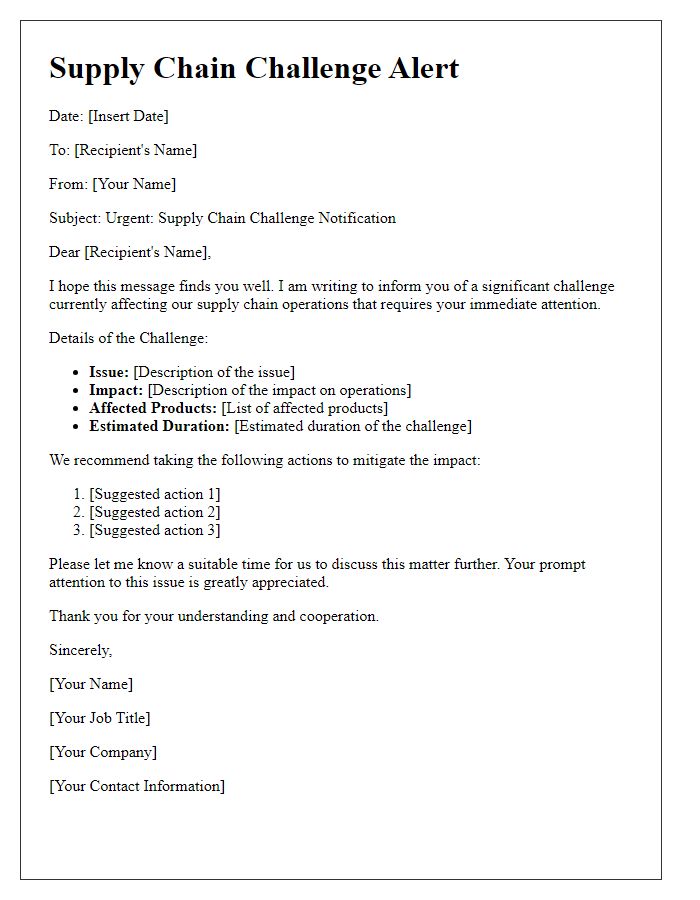

Detailed Mitigation Strategies

Supply chain disruptions pose significant challenges to organizations, affecting delivery timelines and overall operations. For instance, the COVID-19 pandemic caused global logistics delays, with shipping container shortages reported by the World Bank. Companies are implementing detailed mitigation strategies to address these issues. Inventory management systems undergo enhancement to increase stock visibility while shifting to multiple sourcing strategies ensures dependency on a single supplier diminishes. Additionally, companies consider nearshoring--relocating production closer to consumer markets, such as relocating manufacturers from Asia to Mexico for North American businesses. Furthermore, employing advanced analytics helps in predicting potential disruptions, enabling proactive decision-making. Establishing strong communication channels with suppliers and partners fosters collaboration during crises, reinforcing resilience against future uncertainties in the supply chain.

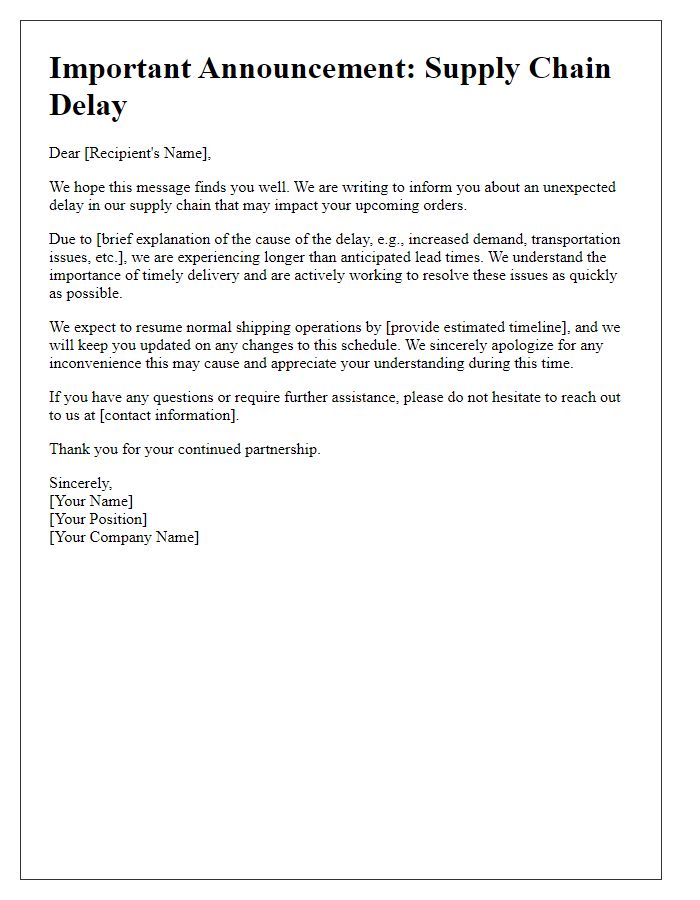

Contact Information for Queries

Supply chain disruptions can significantly impact various industries, causing delays and uncertainty in product deliveries. Companies may experience increased lead times (typically ranging from several days to weeks) due to factors such as global transportation issues and raw material shortages. Customers may seek to address their concerns through effective communication channels. Providing direct contact information (including phone numbers and email addresses) for customer service representatives helps facilitate inquiry resolution. This transparency allows businesses to maintain consumer trust and provide timely updates regarding order statuses and potential delays. Establishing these communication lines is essential for managing expectations and fostering positive relationships with clients.

Request for Collaboration and Understanding

Supply chain disruptions can significantly impact business operations across various industries, including manufacturing, retail, and logistics. Events such as natural disasters, such as Hurricane Ida in 2021, or global pandemics, like COVID-19, have exposed vulnerabilities within supply chains. Specific disruptions may include transportation delays, raw material shortages, and increased freight costs, affecting delivery timelines and inventory levels. Collaboration among stakeholders, including suppliers, manufacturers, and logistics providers, is crucial to navigate these challenges effectively. Regular communication and shared understanding of constraints can help mitigate risks, ensuring timely delivery of products to consumers while maintaining quality standards. Understanding these dynamics is essential for companies to develop strategies that enhance resilience and adaptability in their supply chains.

Comments