If you've ever found yourself tangled in the complexities of addressing a contractor material defect, you're not alone. Many homeowners face challenges when it comes to ensuring that their homes are built with high-quality materials that stand the test of time. Fortunately, understanding how to navigate a material defect claim can save you both time and money. So, let's dive into the essential steps you need to take to protect your investment and make sure your home is everything you dreamt it to beâread on to discover more!

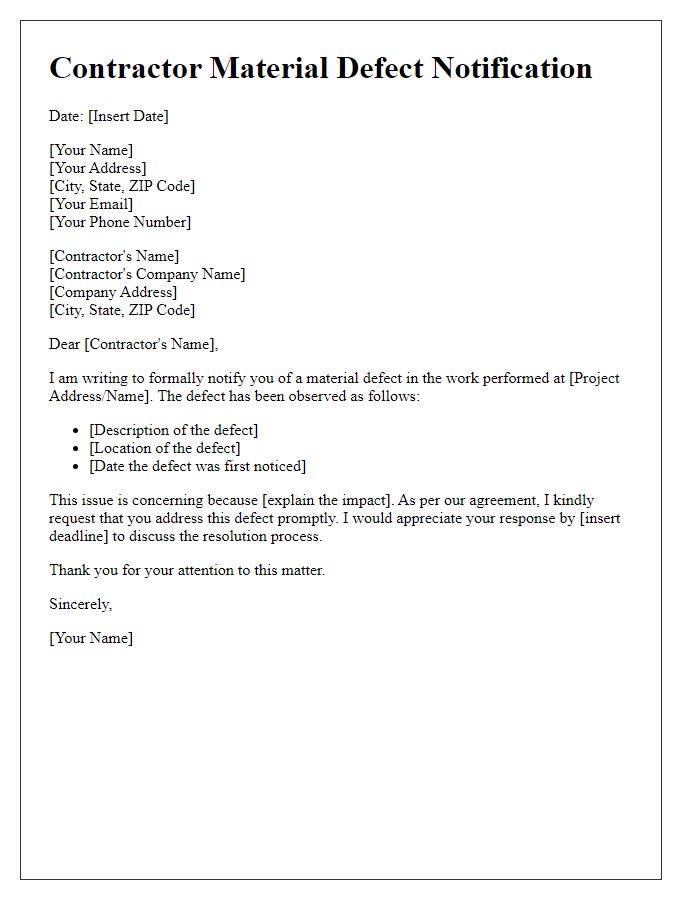

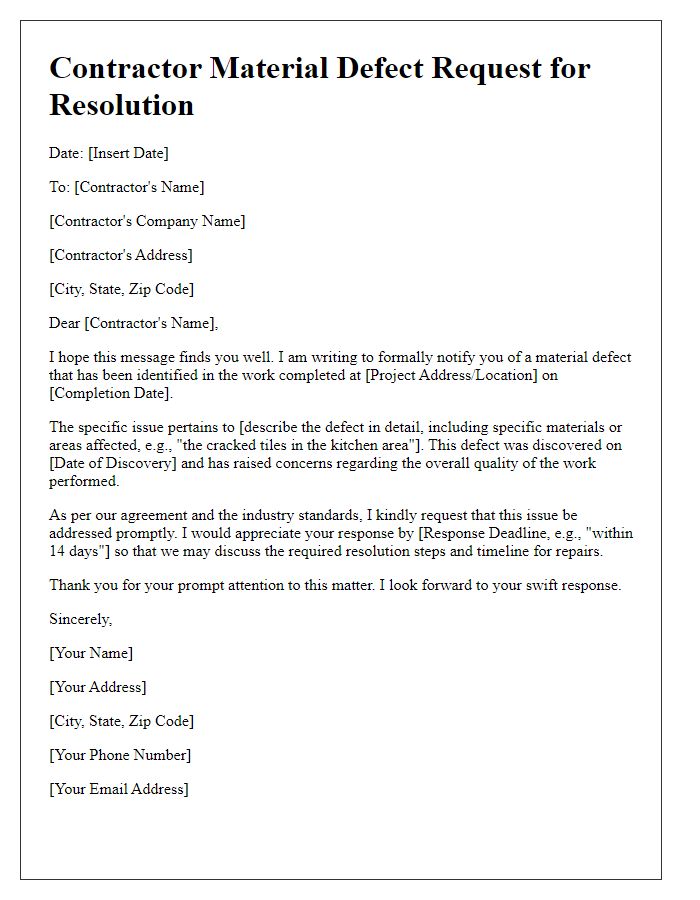

Contract details and reference numbers

A contractor material defect claim often requires precise documentation, including contract details and reference numbers. Essential elements include contract number (a unique identifier for the agreement), project title (the name of the construction or service project), and date of execution (the official date the contract was signed). Reference numbers for any related correspondence or prior claims may also be included, ensuring clarity in communication. Specific defects should be identified, described, and linked back to the contract's terms, highlighting warranties or guarantees violated. Detailed photographs or inspection reports can also strengthen the claim, illustrating the nature and extent of the defects, and providing a thorough basis for any required reparations or replacements.

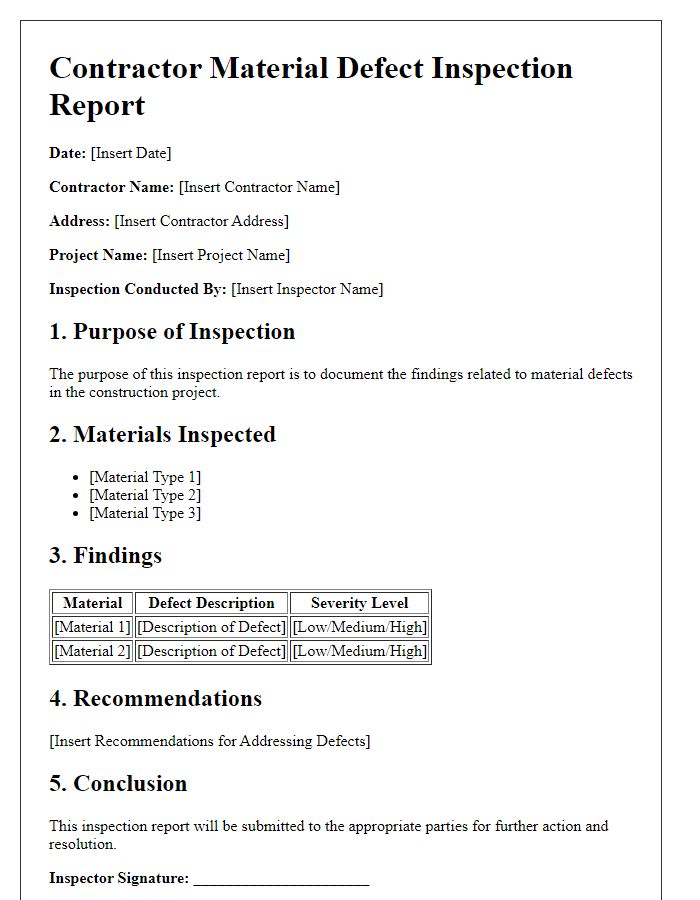

Description of material defect

A recent inspection revealed significant defects in the construction materials used, specifically in the concrete slabs at the project site located in Springfield. The concrete exhibits surface spalling, indicating poor mixing and an improper cement-water ratio that fails to meet the industry standard of 0.5. Additionally, the presence of excessive cracking, with widths exceeding 1/4 inch, suggests inadequate curing practices were employed, likely exposing the material to moisture before it had sufficiently hardened. These defects not only compromise structural integrity but may lead to further deterioration over time, requiring immediate remediation. Furthermore, the steel rebar used, identified as Grade 40, showed signs of corrosion, further indicating a lack of protective measures during installation. The cumulative effect of these material defects necessitates urgent attention to prevent potential hazards and additional costs associated with repairs.

Impact on project timeline and quality

Defective materials in construction projects can significantly impact both the project timeline and overall quality of the build. For instance, using inferior concrete can lead to structural weaknesses, requiring additional inspections and potential rework that delays completion dates by weeks or even months. Similar issues arise with substandard roofing materials, which may compromise insulation and weather resistance, prompting further repairs and increased costs. The time lost in addressing these material defects not only extends the project timeline but also detracts from the quality, resulting in additional resources spent on corrective measures and ultimately affecting client satisfaction and future business opportunities.

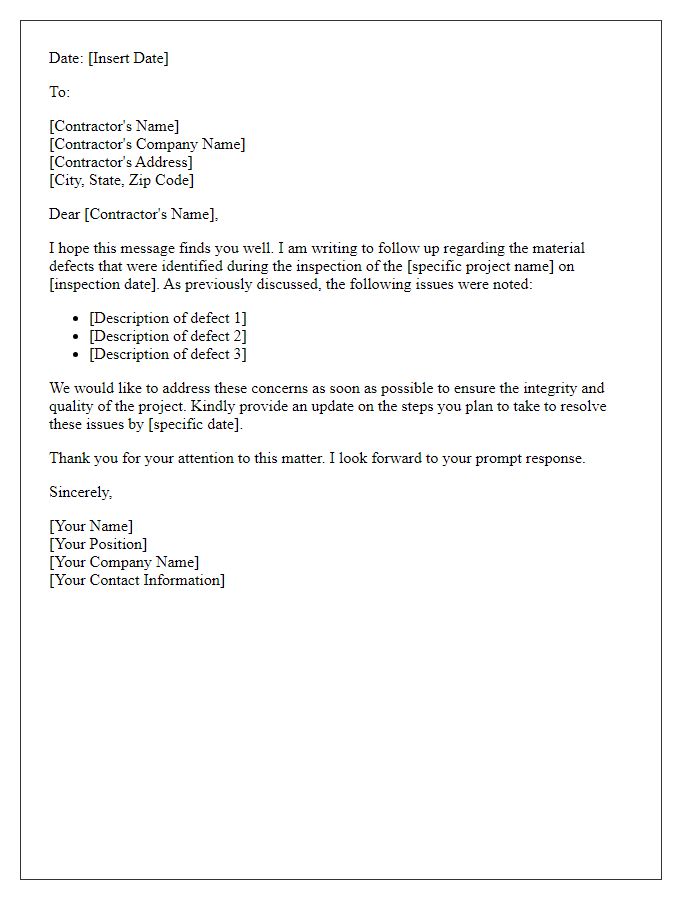

Requested remedial actions

Contractor material defects can lead to significant project delays, financial losses, and safety issues in construction projects like residential buildings or commercial complexes. Remedial actions requested typically include a comprehensive inspection of defective materials such as drywall, roofing materials, or plumbing fixtures, identified during the project lifecycle. Additionally, repair or replacement of these substandard materials should adhere to relevant building codes and standards, such as the International Building Code (IBC). Thorough documentation and evidence, including photographs, inspection reports, and contracts, will support the claim process and detail the extent of the defects and proposed corrective measures. The ultimate objective is to ensure compliance with quality standards and timely project completion.

Supporting documentation and evidence

When filing a contractor material defect claim, it is essential to present comprehensive supporting documentation and evidence to substantiate your case effectively. Key pieces of documentation include the original contract (detailed scope of work, material specifications, and timelines) signed on January 15, 2023, which outlines expectations and responsibilities. Photographic evidence showcasing the defects (such as cracked tiles and peeling paint) taken on March 10, 2023, provides visual confirmation of material issues. Inspection reports from certified professionals (such as structural engineers) dated March 12, 2023, detail the severity and potential consequences of the material defects. Email correspondence with the contractor, including requests for remediation dated April 1, 2023, serves to show attempts at resolution. Receipts for replacement materials purchased due to the defects (totaling $2,500) bolster your claim for damages incurred. Lastly, any witness statements from individuals observing the project timeline (such as neighbors) can further validate your claims and establish a timeline of events related to the defect issues.

Comments