When it comes to maintaining strong partnerships, supplier evaluation feedback plays a crucial role in ensuring that both parties are aligned and thriving. It's an opportunity to share insights, celebrate successes, and identify areas for improvementâall in the spirit of collaboration. By openly communicating your thoughts and observations, you foster transparency and create a foundation for enhanced efficiency and mutual growth. Ready to dive deeper into effective feedback strategies? Let's explore more!

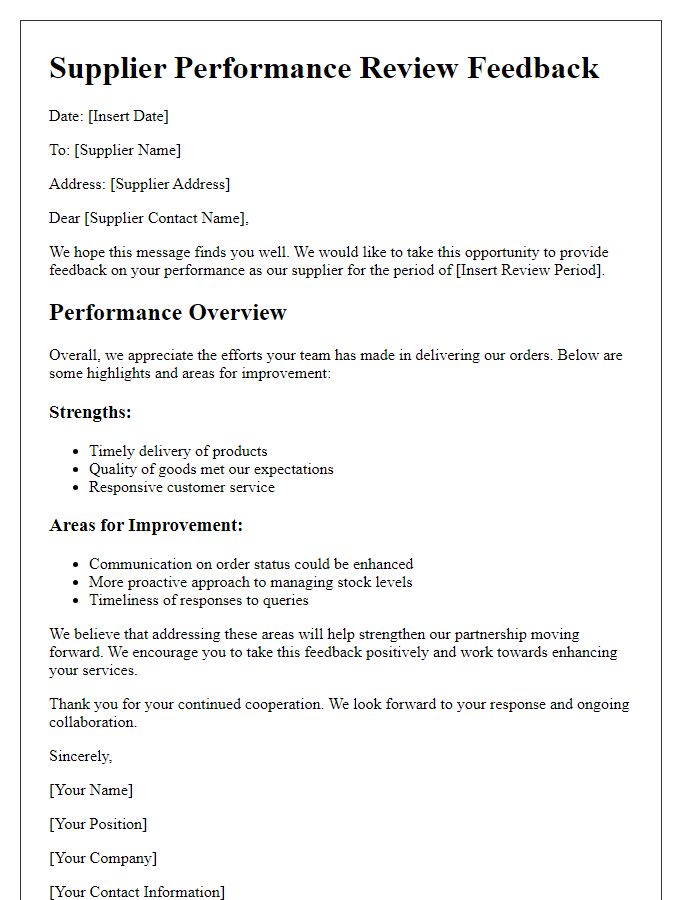

Clear and concise communication

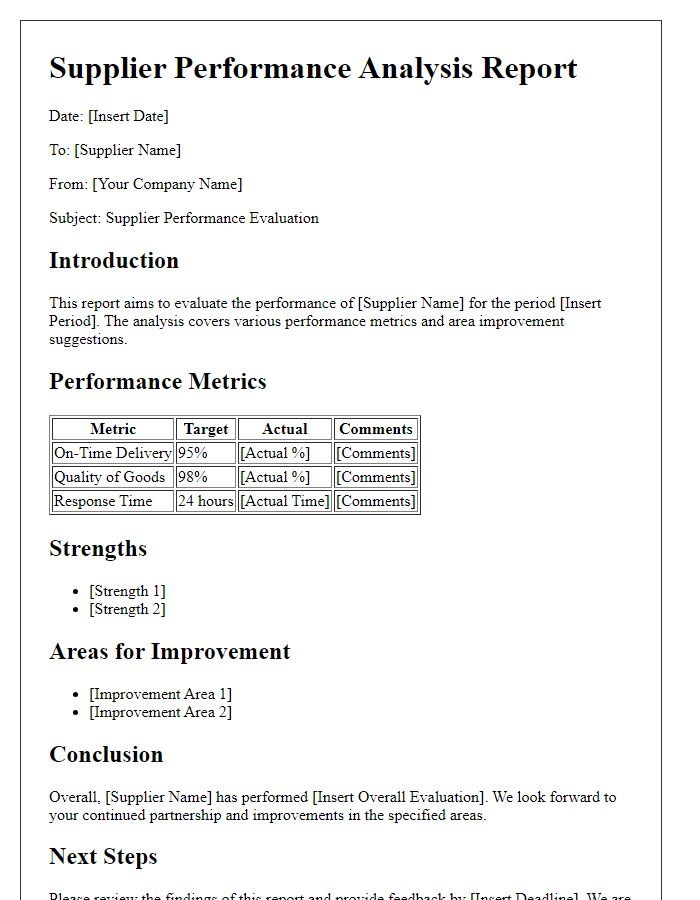

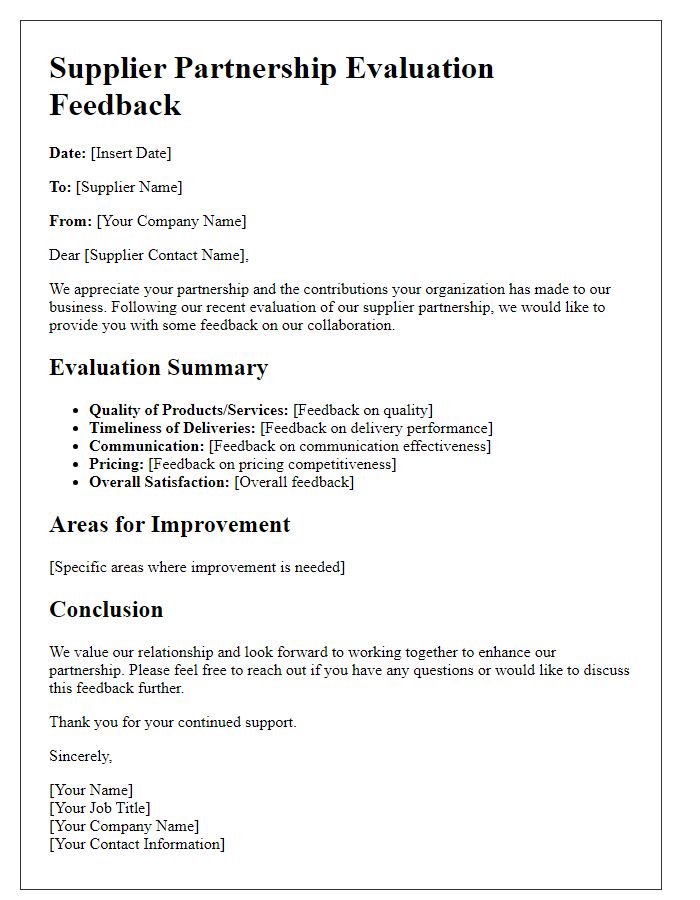

Effective supplier evaluation requires clear and concise communication to ensure mutual understanding and cooperation. Key factors include timely feedback on product quality (measured through defect rates), delivery performance (tracked through on-time delivery percentages), and customer service responsiveness (assessed via average response times). Utilizing measurable criteria, such as the Net Promoter Score (NPS), helps quantify supplier reliability. Regular assessments allow for ongoing improvements and adjustments in the partnership. Establishing a standardized feedback process can enhance collaboration and strengthen the supplier relationship, ultimately contributing to a more efficient supply chain.

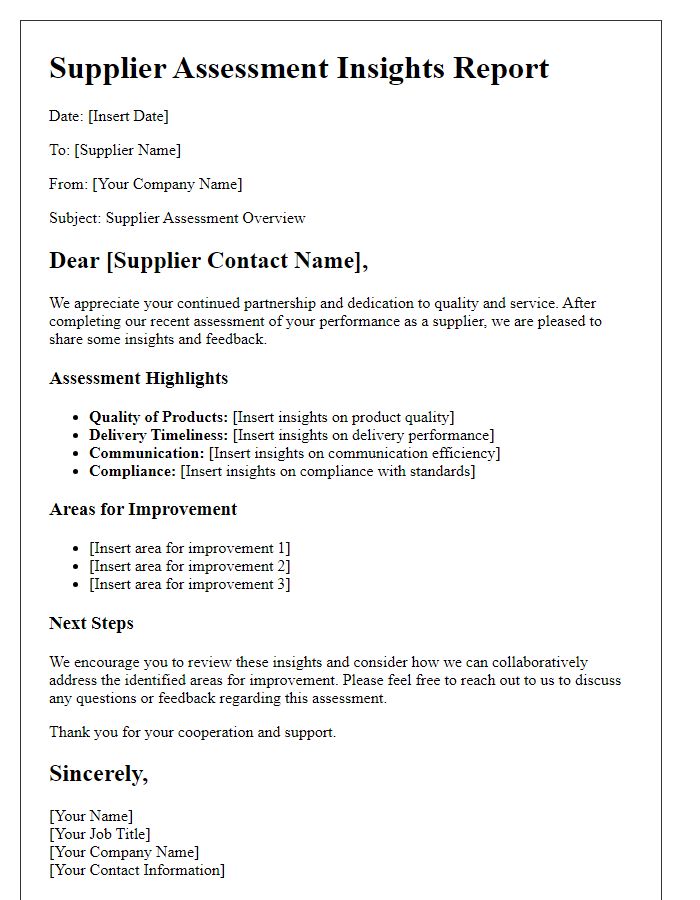

Specific performance metrics

Supplier evaluation feedback focuses on several specific performance metrics. On-time delivery rates, ideally exceeding 95%, indicate reliability in meeting deadlines for supply deliveries. Quality assurance metrics should show less than 2% defect rates in supplied materials, which reflect adherence to quality standards and specifications. Communication responsiveness is crucial, with a target of responding to inquiries within 24 hours to facilitate smooth operations. Additionally, pricing competitiveness must be assessed, ensuring that costs remain within 10% of market averages without compromising quality. Lastly, compliance with industry regulations and standards, such as ISO certifications, demonstrates a commitment to best practices in supply chain management.

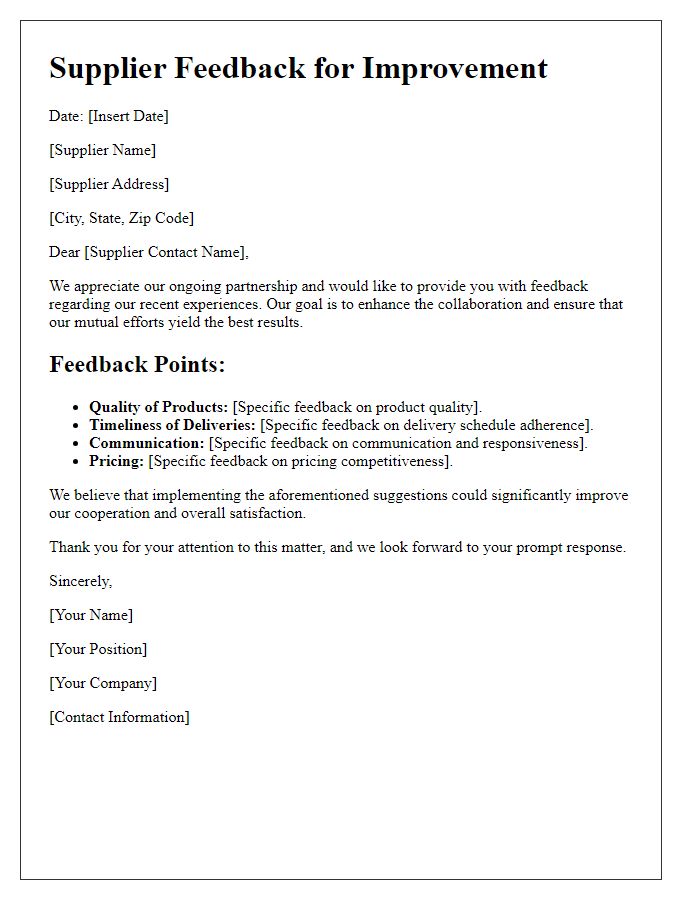

Constructive and actionable feedback

Supplier evaluation feedback plays a pivotal role in maintaining quality standards within the supply chain. Quality control measures should include clear metrics for performance assessment, such as delivery times and product quality. Addressing delivery timelines, it's crucial to note that recent shipments to New York City experienced delays exceeding five days, impacting project schedules. In terms of product quality, a 15% defect rate was observed in the last quarter's shipment, particularly concerning electronic components like resistors and capacitors, which need immediate attention. Communication also remains vital; a more proactive approach in updates during the order process would be beneficial. Establishing weekly check-ins can facilitate better alignment on expectations and timelines, fostering a more collaborative partnership moving forward.

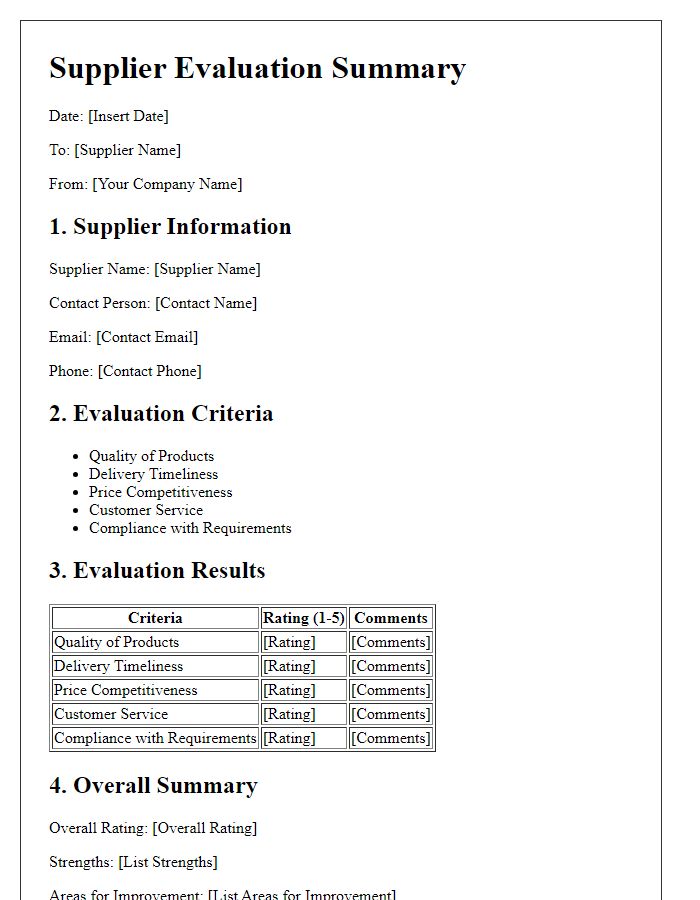

Positive aspects and areas for improvement

Supplier evaluation feedback highlights strengths and opportunities for growth. Positive aspects include timely delivery from Supplier A, maintaining an on-time shipment rate of 95%, ensuring inventory is consistently stocked. Quality control measures display effectiveness with a defect rate of less than 1%, reflecting adherence to industry standards. Communication demonstrates clarity and responsiveness, leading to efficient collaboration on joint projects. Areas for improvement involve streamlining invoicing processes, as delays in billing submissions have been noted, potentially affecting cash flow management. Additionally, expanding product range to include eco-friendly materials could align with sustainability initiatives being prioritized by many businesses in 2023. Regular training sessions on inventory management also appear beneficial for enhancing operational efficiency.

Future collaboration expectations

Effective supplier evaluation feedback shapes future collaboration and strengthens partnerships. The evaluation process should involve clear metrics such as quality assurance, delivery timelines, and cost-effectiveness. Suppliers, like Company XYZ, must consistently meet agreed-upon standards and adapt to changes in production demands. Performance indicators, including on-time delivery rates exceeding 95% and product defect rates below 1%, are crucial benchmarks. Communication channels need transparency to facilitate timely updates on inventory levels or potential production delays. Engagement in sustainability practices, like reducing carbon footprints and waste, is increasingly important in selecting suppliers for long-term strategic alliances. Regular meetings, scheduled quarterly, can ensure alignment on expectations and goals moving forward.

Comments