Hey there! If you're diving into the world of construction project logistics coordination, you're in for an exciting journey. Effective communication is key, as it ensures every piece of equipment, material, and workforce is perfectly aligned for the task at hand. In this article, we'll explore essential strategies and practical tips to streamline the logistics process, making your projects not only efficient but also more successful. So, buckle up and read on to enhance your coordination skills!

Detailed Project Schedule

A detailed project schedule is essential for effective logistics coordination in construction projects. This schedule typically covers significant milestones, including project initiation dates, procurement timelines, and critical completion deadlines. The phases may include site preparation (expected to commence on January 15, 2024), foundation work (scheduled for February 1, 2024), and structural framing (planned for March 15, 2024). Key resource allocations, such as labor (with a workforce projected to peak at 50 personnel during the foundation phase) and material supplies (including 500 cubic yards of concrete), should be meticulously tracked to avoid delays. Interdependencies between tasks must be identified, such as the reliance of electrical work on the completion of rough framing by April 30, 2024. Regular updates and adjustments to the schedule (anticipated on a bi-weekly basis) will ensure all team members remain aligned with project timelines and objectives.

Comprehensive Material Inventory

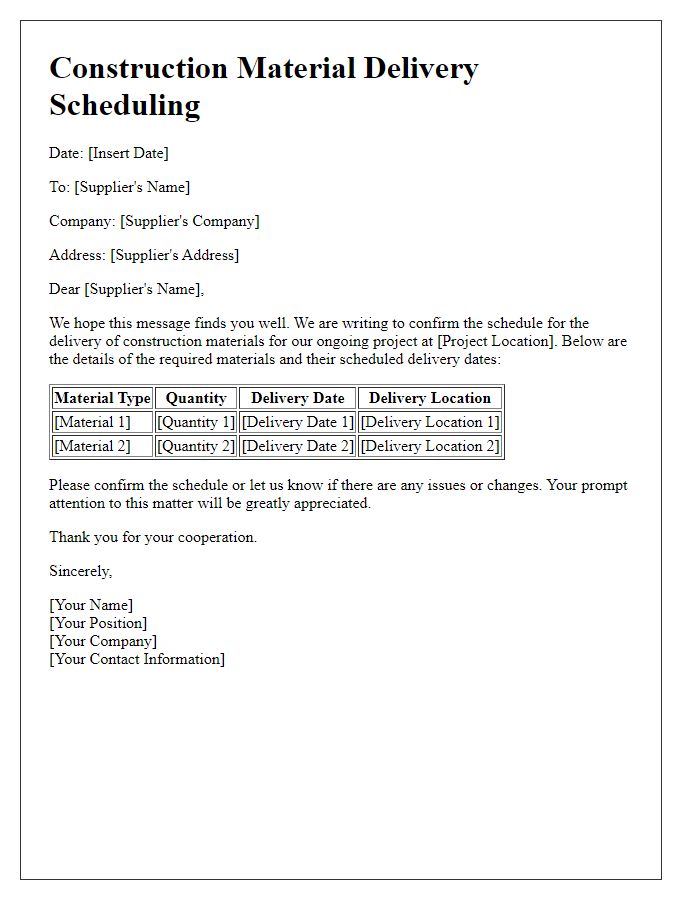

In the realm of construction project logistics coordination, a comprehensive material inventory serves as a vital tool for ensuring the smooth progression of operations. This inventory includes an extensive list of essential supplies such as concrete (weighing approximately 2,400 kg per cubic meter), steel beams (often ranging from 6 to 12 meters in length), and insulation materials (with R-values indicating thermal resistance). Location specifications, such as job site addresses (e.g., 123 Main Street, Springfield) and delivery timelines (typically requiring advance notice of at least 48 hours), must be meticulously documented. Additionally, monitoring the quantity of each item, such as the number of bricks (standard size being 190 mm x 90 mm x 90 mm), and ensuring compliance with safety regulations (e.g., OSHA standards) is critical. The incorporation of tracking systems for materials using GPS tags enhances the efficiency of logistics, minimizing delays and optimizing resource utilization throughout the project's lifecycle.

Clear Communication Protocols

Effective communication protocols are vital in construction project logistics coordination, where multiple partners such as subcontractors, suppliers, and project managers (up to 20+ entities) must synchronize operations. Utilizing project management software like Procore or Microsoft Project facilitates seamless updates across all stages of the logistics chain. Scheduled weekly meetings at construction sites ensure alignment on progress updates and material deliveries (often involving hundreds of items), while designated point persons streamline inquiries and address issues promptly. Recent studies indicate that projects with clear communication protocols can reduce delays by 30%, emphasizing their importance in maintaining timelines and budgeting. Implementing tools like shared digital platforms enhances visibility for all stakeholders involved, fostering accountability and minimizing misunderstandings throughout the project lifecycle.

Efficient Transportation Plans

Efficient transportation plans are crucial for construction project logistics, ensuring timely delivery of materials, equipment, and workforce to sites such as the ongoing downtown high-rise development in Chicago. Effective management of transportation routes, utilizing traffic data from sources like the Department of Transportation, aids in minimizing delays due to congested areas, especially during peak hours. Coordination with suppliers such as cement manufacturers and steel fabricators ensures that key materials arrive just-in-time, maintaining the project schedule. The use of GPS tracking systems for vehicles enhances real-time monitoring of deliveries, contributing to operational efficiency. Compliance with local regulations for oversized loads is essential, as is obtaining necessary permits for night-time transport in high-density zones to prevent disruption. Comprehensive communication with project stakeholders, including site managers and subcontractors, is vital to address any logistical challenges that may arise during transit.

Risk Management Strategies

Effective risk management strategies in construction project logistics coordination involve identifying potential hazards, assessing their impact, and implementing proactive measures. For instance, delays caused by inclement weather can impact project timelines significantly, often resulting in cost overruns. Utilizing advanced weather forecasting tools can help predict adverse conditions and adjust schedules accordingly. Moreover, supply chain interruptions can occur due to unforeseen events, such as natural disasters affecting suppliers' locations, so diversifying suppliers across different regions minimizes reliance on a single source. Safety protocols must be strict, emphasizing personal protective equipment (PPE) and safety training sessions for workers on-site to reduce injury-related downtime. Regular communication between all stakeholders, including contractors, suppliers, and local authorities, ensures seamless coordination and swift response to emerging risks, promoting overall project success.

Letter Template For Construction Project Logistics Coordination Samples

Letter template of construction project logistics management coordination

Comments