Hey there! We all know that life can throw unexpected curveballs, especially when it comes to supply chain logistics. Whether it's due to unforeseen delays or changes in production timelines, modifying a delivery schedule can be both necessary and tricky. If you've ever found yourself in need of a reliable letter template for notifying your supplier about a delivery schedule change, you're in the right placeâlet's dive in and explore the essential elements you need. Stay tuned for our easy-to-follow guide that will help you craft the perfect message!

Clear Subject Line

Supplier delivery schedule changes require effective communication to ensure all parties involved are aware of updates. A clear subject line, such as "Update on Delivery Schedule for Order #12345," establishes context. The body of the message should include key details, like the new delivery dates, reasons for the change, and any necessary actions required from the supplier. Specific items affected can include product categories, quantities, and any potential impact on inventory levels. Providing contact information for follow-up questions emphasizes the importance of collaboration in adjusting to the new timeline.

Supplier Contact Information

Suppliers can experience unexpected capacity changes, leading to adjustments in delivery schedules. For instance, a supplier managing logistics across multiple regions, such as North America and Europe, may encounter delays due to geopolitical events or changes in transportation regulations. Companies might need to communicate the revised delivery timeline effectively, as this can significantly impact production schedules and inventory levels. Clear notification--including updated dates and specific quantities--can help businesses recalibrate their operations and minimize disruption. It's crucial that suppliers maintain open lines of communication to address any concerns about these changes.

Specific Reason for Change

Supplier delivery schedules often require adjustments due to unforeseen circumstances like increased demand, logistics issues, or supply chain disruptions. For instance, a rise in customer orders may necessitate earlier delivery dates to maintain stock levels. Similarly, an unexpected delay in shipping routes due to inclement weather conditions, such as hurricanes in the Atlantic, could mandate a revision of agreed-upon timelines. Communication with suppliers is essential, detailing the specific reasons and proposing new dates to ensure alignment and minimize potential disruptions in production processes.

Revised Delivery Timeline

Revised delivery schedules for suppliers can significantly impact operational efficiency. Timely adjustments communicated clearly can help avoid disruptions. Supplier delivery timelines should reflect data-driven insights, influenced by factors such as production capacity changes or logistical challenges. For instance, a change from a weekly delivery to a bi-weekly schedule may arise from a limited supply of raw materials like steel for manufacturing. Additionally, collaboration with transportation partners, such as UPS or FedEx, to accommodate these changes holds importance. Maintaining transparency with stakeholders about new timelines fosters trust and reliability in business relationships, enabling a smoother transition to revised plans.

Contact for Further Clarification

A supplier delivery schedule change may significantly impact inventory management, logistics operations, and production timelines. Suppliers, such as XYZ Corp, should inform their partners in advance about any adjustments to the agreed shipping dates. Key details include the new delivery dates and how they affect current orders. Additional context regarding potential delays caused by unforeseen events (e.g., supply chain disruptions, weather conditions) is essential for facilitating transparent communication. Companies should reach out to designated contacts, such as Jane Doe from the procurement department, for further clarification on the implications of these changes on contract fulfillment and operational efficiency. Clear guidelines for adjusting stock levels in warehouses must also be established to mitigate disruptions in the supply chain.

Letter Template For Supplier Delivery Schedule Change Samples

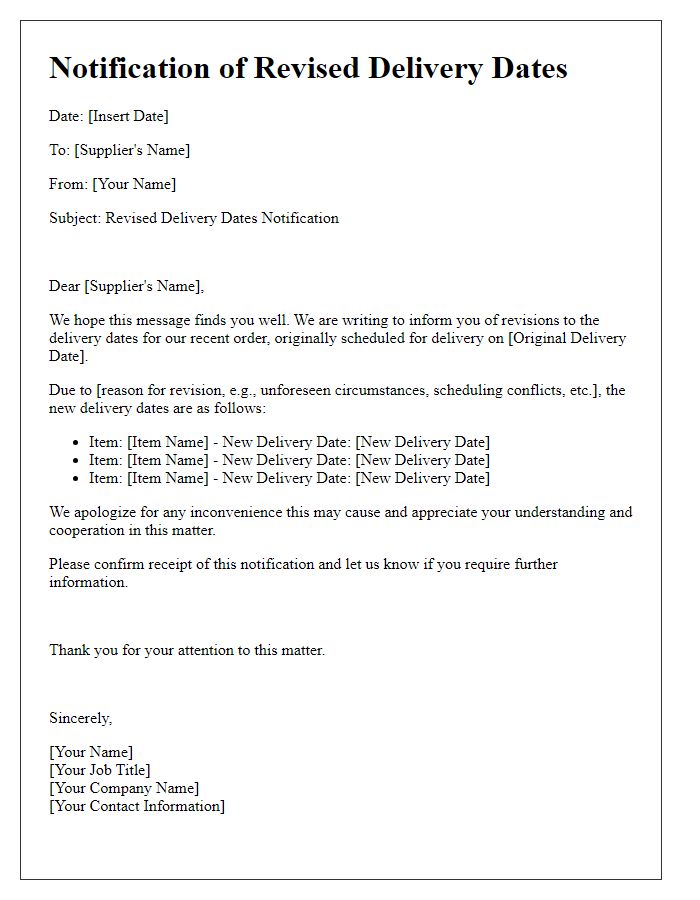

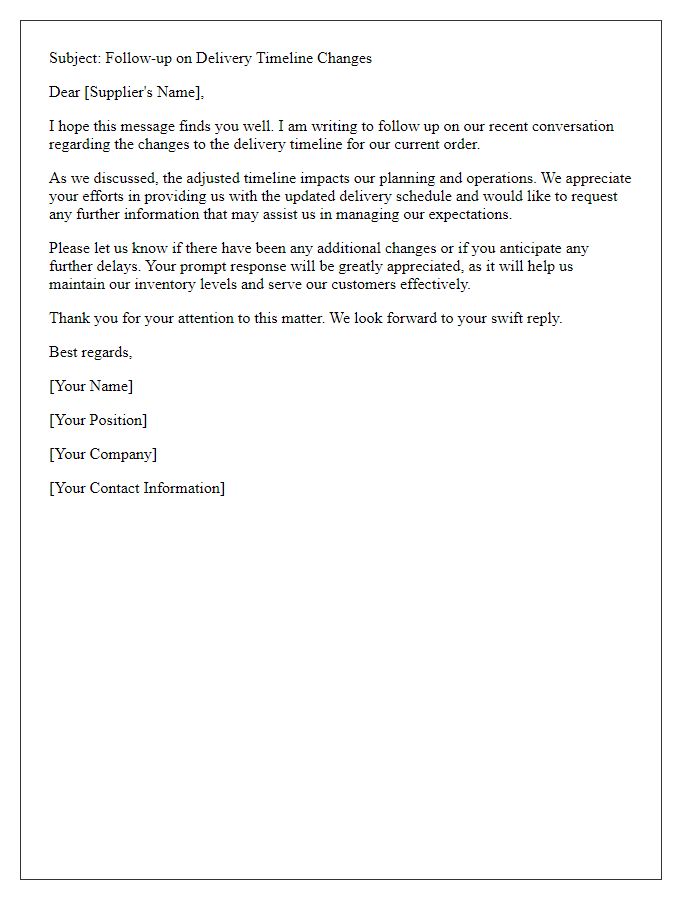

Letter template of notification for revised delivery dates from supplier

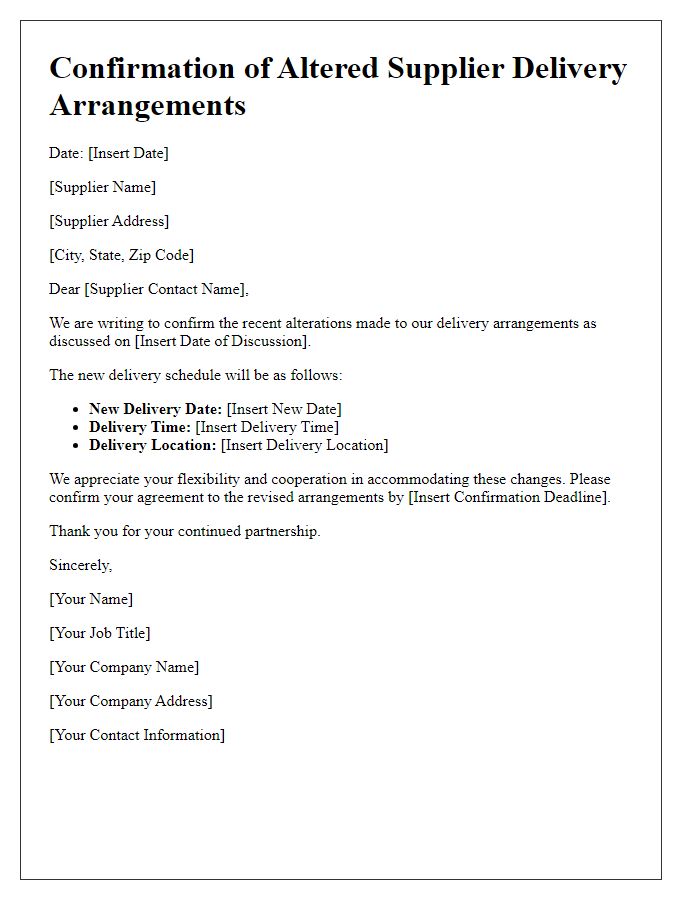

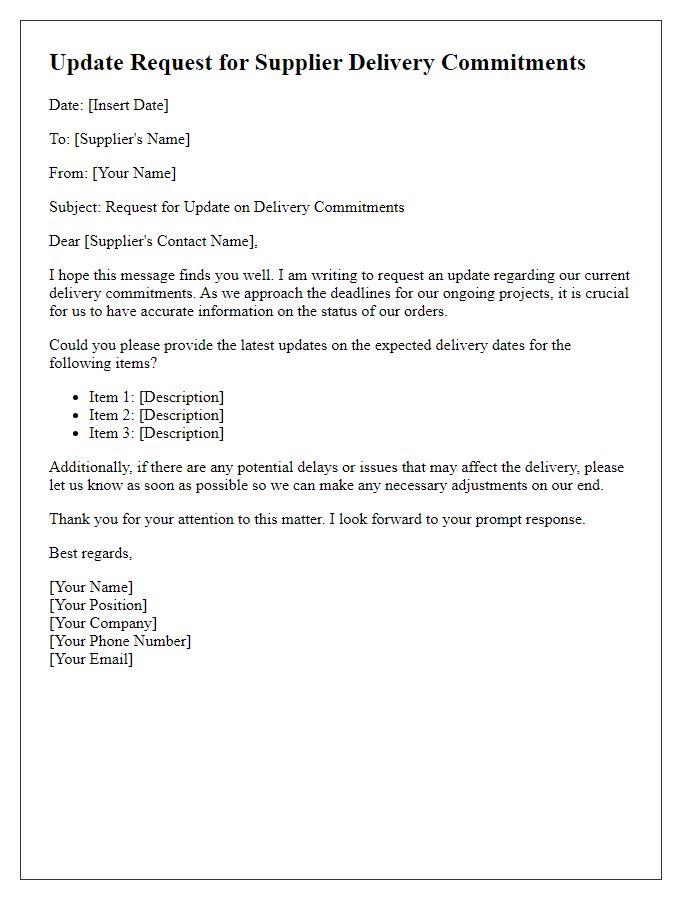

Letter template of confirmation for altered supplier delivery arrangements

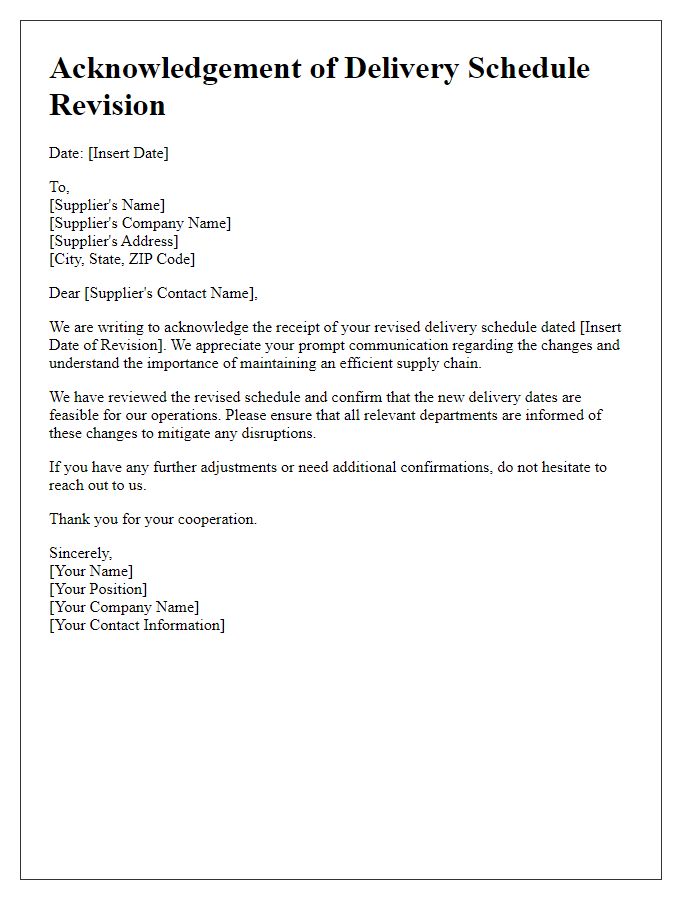

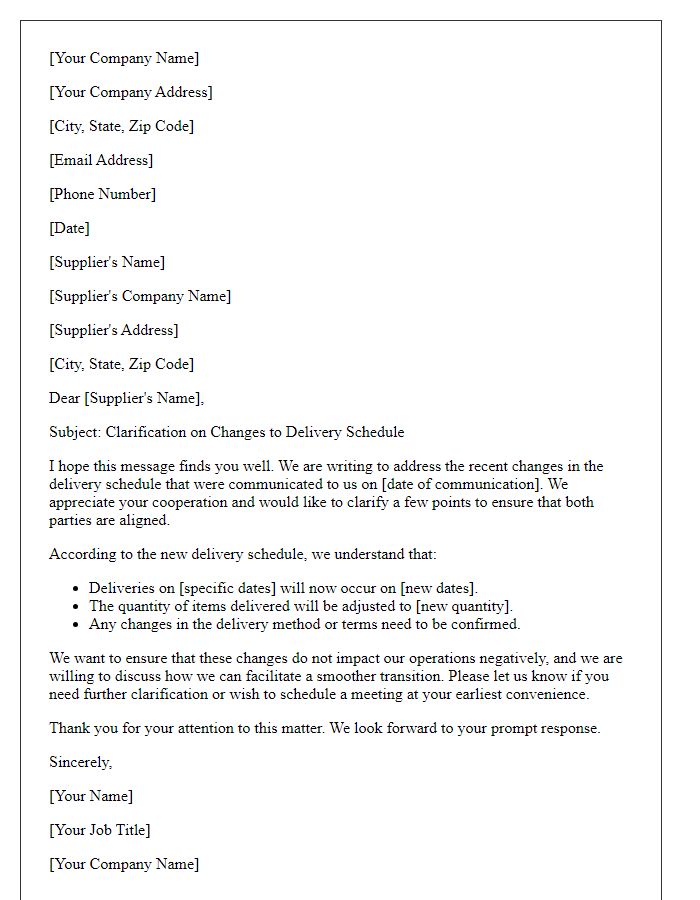

Letter template of acknowledgement for supplier delivery schedule revision

Comments