Hey there! If you're feeling the pressure of long vendor lead times impacting your business efficiency, you're not alone. Many companies are seeking innovative ways to streamline their supply chains and foster better relationships with their vendors. In this article, we'll explore practical strategies for proposing lead time reductions to your suppliers, ensuring you stay competitive and responsive to market demands. So, let's dive in and discover how you can effectively communicate your proposal!

Current Lead Time Assessment

Current lead time assessment for vendor partnerships reveals significant delays impacting supply chain efficiency. Average lead times, spanning from order placement to delivery, reportedly exceed 30 days for key components. Suppliers located in Asia, such as those in China and Vietnam, contribute to the extended time frames due to logistical challenges, customs processing, and production schedules. In certain cases, high-demand periods exacerbate delays, resulting in order fulfilment issues. Reducing this lead time is critical for maintaining competitiveness in fast-paced markets where timely product availability dictates customer satisfaction and sales performance. A targeted strategy addressing these inefficiencies could yield improvements of up to 15 days, enhancing overall operational productivity.

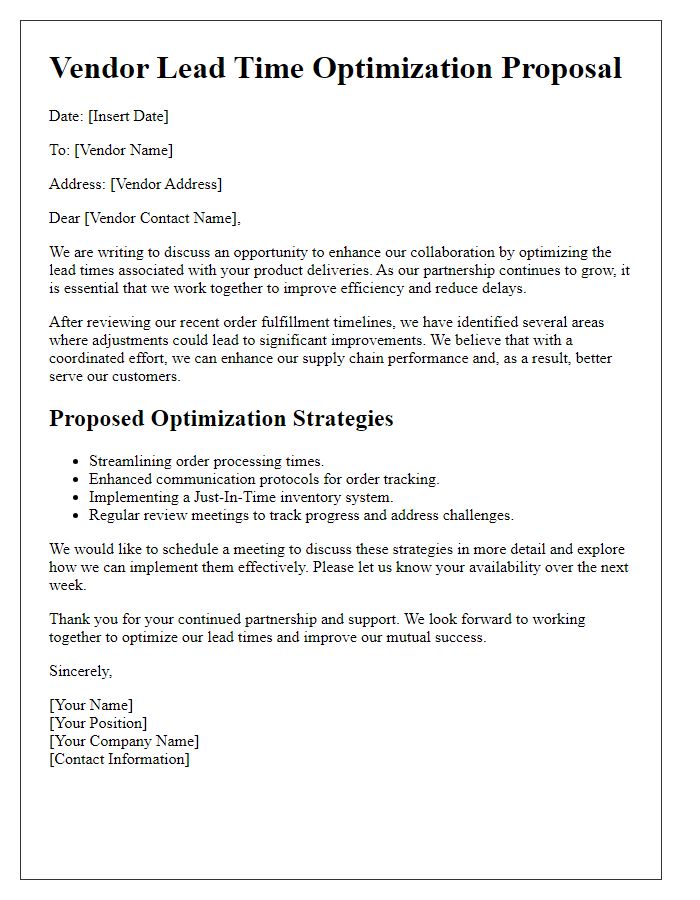

Proposed Lead Time Reduction Strategies

Proposed lead time reduction strategies in supply chain management can significantly enhance operational efficiency for companies like ABC Manufacturing. Implementing Just-In-Time (JIT) inventory management optimizes stock levels, reducing storage costs and minimizing waste from excess inventory. Establishing stronger relationships with key suppliers in regions like Southeast Asia can lead to quicker response times and improved communication, thus decreasing overall lead times. Additionally, utilizing advanced forecasting techniques and data analytics enables companies to better anticipate demand fluctuations, resulting in more accurate ordering schedules. Streamlining transportation logistics through partnerships with reliable carriers and using technology for real-time tracking can expedite delivery and enhance visibility across the supply chain. Adopting these methods can lead to improved customer satisfaction and increased competitiveness in today's market.

Benefits of Lead Time Reduction

Reducing lead time in supply chain management presents significant benefits for businesses. Enhanced efficiency allows for faster response to customer demands, improving satisfaction rates and loyalty. Companies like Amazon implement streamlined processes, resulting in lead times as short as one day, dramatically increasing sales potential. Reduced inventory costs emerge as shorter lead times minimize the need for excess stock. For instance, automotive companies adopting just-in-time manufacturing significantly decrease holding costs. Improved production planning becomes feasible with reduced lead times, allowing firms to anticipate demand fluctuations better. Enhanced supplier relationships often develop as vendors cooperate closely to meet tighter deadlines, facilitating smoother communication and collaboration. Overall, lead time reduction supports competitive advantage in rapidly changing markets, empowering businesses to adapt swiftly to industry trends.

Collaboration and Support Mechanisms

Effective collaboration is essential for reducing vendor lead times, particularly in supply chains involving multiple stakeholders. A comprehensive review of current lead times reveals that, on average, they span anywhere from 4 to 12 weeks, depending on product complexity and supplier location. Implementing support mechanisms such as real-time communication tools, like Slack or Teams, can facilitate immediate updates and resolve issues swiftly, potentially decreasing delays significantly. Additionally, adopting inventory management systems, such as Just-In-Time (JIT) inventory methods, can improve stock levels and reduce lead time by ensuring materials are available just as needed. Initiating regular review meetings (bi-weekly or monthly) with key suppliers located in logistic hubs, like Shenzhen or Rotterdam, can foster better relationships, aligning expectations and encouraging proactive problem-solving. Implementing these strategies may lead to a reduction in lead times by up to 30%, enhancing overall operational efficiency and customer satisfaction.

Implementation Timeline and Milestones

The proposal for vendor lead time reduction focuses on enhancing supply chain efficiency (the flow of goods and services from suppliers to customers) through a clearly defined implementation timeline. This timeline includes key milestones such as vendor assessment (conducting a review of current suppliers to identify inefficiencies), engagement with stakeholders (involving key internal and external parties to gather insights), and process mapping (analyzing existing workflows to identify bottlenecks), all to be completed within the first quarter of 2024. Following this, the second quarter will focus on developing and testing improvement strategies, like just-in-time inventory practices (minimizing inventory costs while ensuring timely delivery) and performance metrics (criteria to measure success in speed and reliability). Finally, implementation of the final changes will occur in the third quarter, aiming for a 30% reduction in lead times (the duration from order to delivery), with ongoing evaluations to ensure sustained improvements.

Comments