Are you tired of the chaos that comes with managing your transportation services? Planning a maintenance schedule is not just a necessary task; it's essential for keeping your vehicles running smoothly and efficiently. By knowing when to service each vehicle, you can reduce downtime and enhance overall performance. Curious to learn how to create an effective maintenance schedule? Read on for a comprehensive guide!

Company Details

Regular maintenance for transportation services is crucial to ensure safety and reliability. Scheduled inspections typically occur every 5,000 miles for fleets using diesel engines, while electric vehicles may undergo checks every six months. Components like the braking system, tire condition, and fluid levels are routinely inspected by certified technicians. Tracking service records at a central database, such as fleet management software, provides visibility on maintenance history and upcoming service dates. Locations like maintenance depots should be equipped with specialized tools and facilities to handle various vehicle types, including buses and trucks, adhering to industry regulations set by organizations like the Department of Transportation.

Maintenance Schedule Overview

The transportation service maintenance schedule is vital for ensuring the reliable operation of fleet vehicles, such as buses and trucks. Routine check-ups include essential assessments of engine performance, braking systems, and tire conditions, typically occurring every 5,000 miles or six months, whichever comes first. Preventive maintenance, including oil changes and fluid inspections, significantly reduces the risk of mechanical failures that can disrupt service routes in urban areas like New York City. Additionally, adherence to this schedule helps comply with safety regulations set forth by the Department of Transportation, ensuring passenger safety and reducing liability risks. Maintenance records must be meticulously documented for each vehicle, aiding in compliance audits and tracking maintenance history. Timely servicing can also enhance fuel efficiency, saving operational costs in the long run.

Vehicle Maintenance Checklist

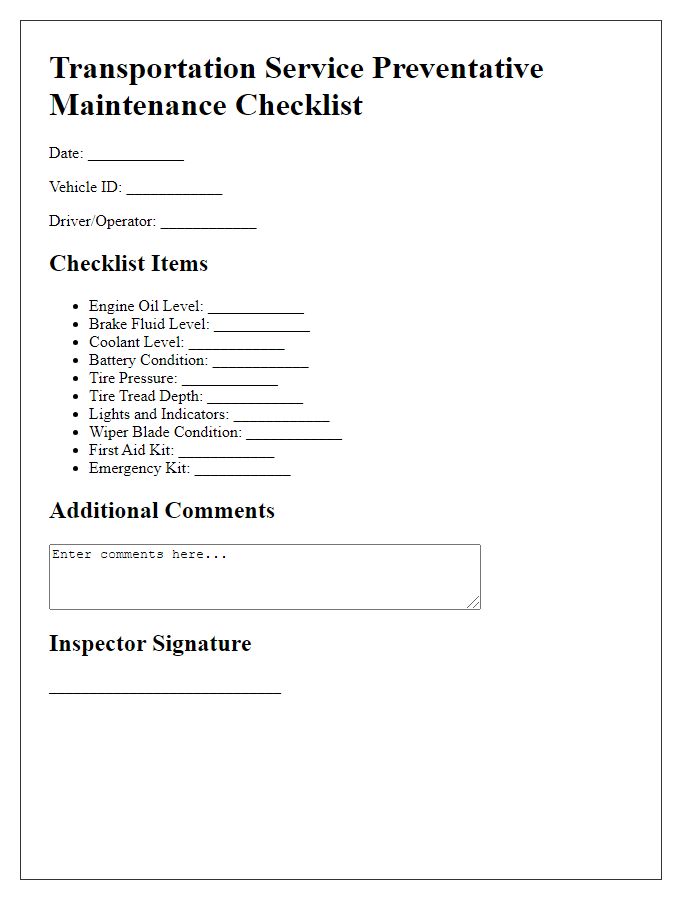

A vehicle maintenance checklist serves as an essential guide for transportation service providers to ensure operational efficiency and safety. Regular inspections (ideally every 3,000 to 5,000 miles) are pivotal in maintaining vehicles like buses, trucks, and vans. Common components include engine oil levels, tire pressure (maintaining between 30-35 PSI), brake fluid, and coolant levels. Key systems such as the transmission and electrical system must be examined quarterly to avoid potential failures. Additionally, safety equipment like fire extinguishers and first aid kits should be checked biannually to ensure compliance with local transportation regulations, such as those mandated by the Department of Transportation (DOT). Consistent adherence to a detailed maintenance schedule can greatly extend the lifespan of vehicles while significantly reducing the risk of on-road incidents.

Contact Information for Queries

A transportation service maintenance schedule is essential for ensuring the safety and reliability of vehicles such as buses, trucks, and vans. Regular inspections and servicing, typically every 3,000 to 5,000 miles, help identify issues such as oil changes, brake checks, and tire rotations to maintain optimal performance. The maintenance team conducts records of services performed, which can help in analyzing any recurring problems with specific vehicle models like Ford or Volvo. Important contact information for queries, including maintenance officer names and phone numbers, provide immediate support for scheduling and emergency repairs. Clear communication within the organization fosters an efficient transportation network, significantly reducing downtime and enhancing service delivery to clients.

Closing Remarks and Signature

Transportation service maintenance schedules require careful attention to ensure the fleet remains operational and safe. Regular checks on critical components, such as brakes, tires, and engines, should follow a detailed plan laid out monthly or quarterly. Preventive maintenance ensures compliance with regulations set forth by agencies like the Federal Motor Carrier Safety Administration (FMCSA), which can lead to significant cost savings and reduced downtime. Each vehicle should be recorded with its respective maintenance history, which includes dates, parts replaced, and any observed issues, allowing for better decision-making and resource allocation in the future. Note: Proper record-keeping aids in tracking vehicle reliability and assists with warranty claims, lowering long-term operational costs.

Letter Template For Transportation Service Maintenance Schedule Samples

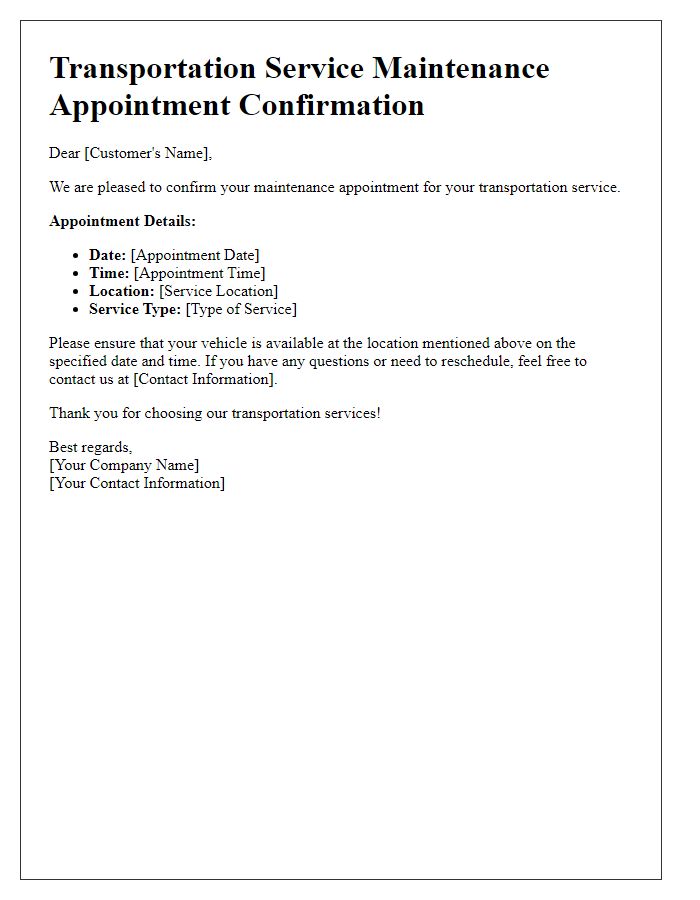

Letter template of transportation service maintenance appointment confirmation.

Letter template of transportation service preventative maintenance checklist.

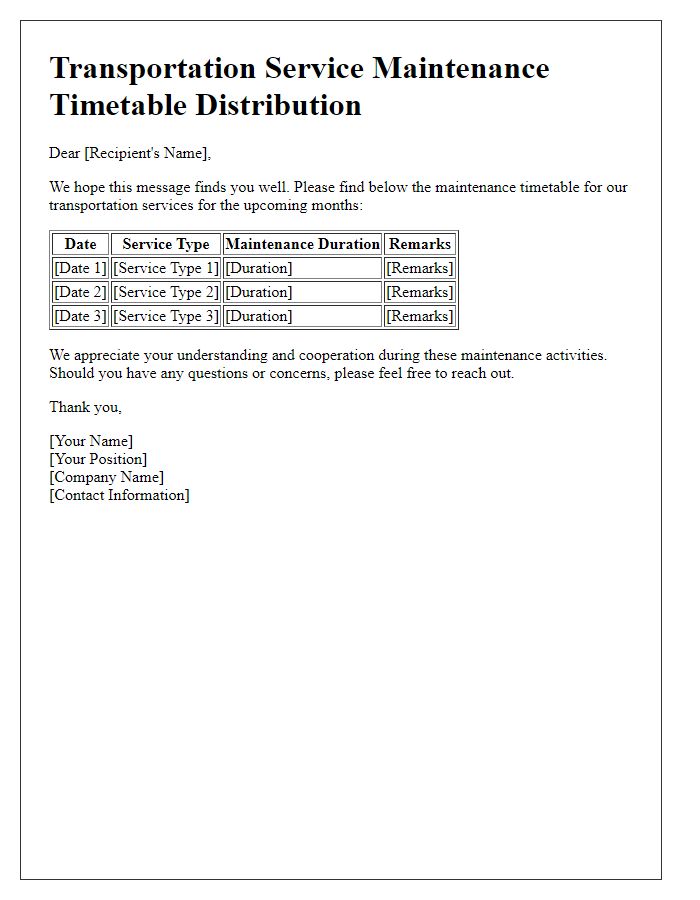

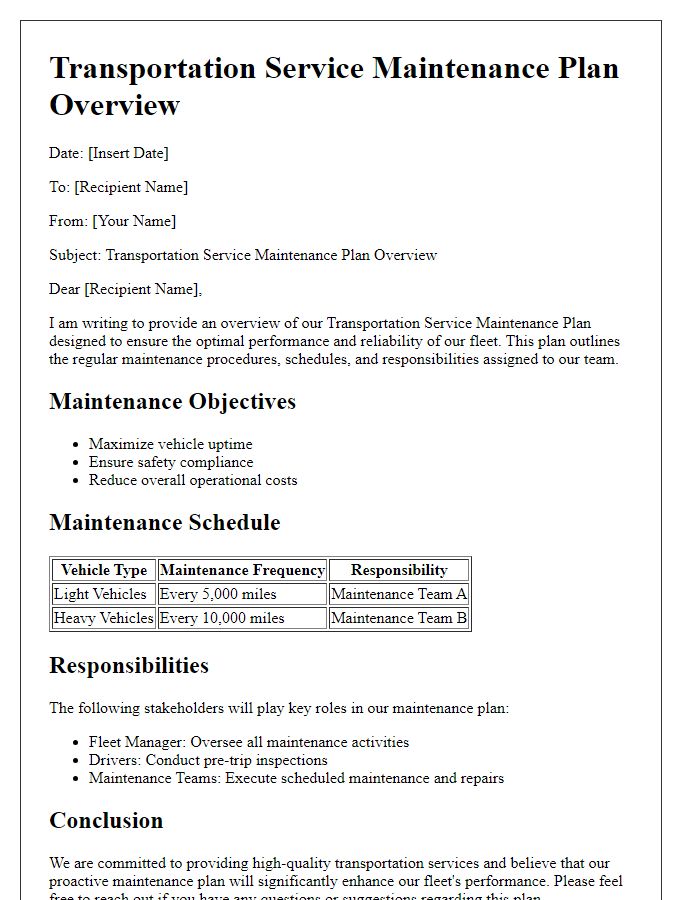

Letter template of transportation service maintenance timetable distribution.

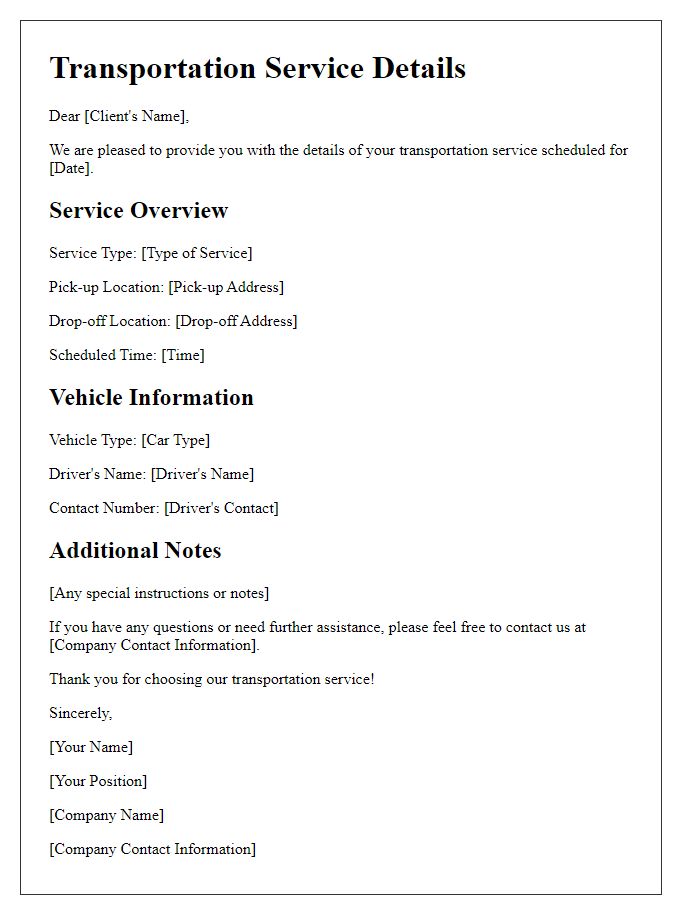

Letter template of transportation service servicing details communication.

Comments