Are you facing issues with freight discrepancies and wondering how to address them? In today's fast-paced logistics world, understanding the nuances of freight management is crucial for ensuring smooth operations. A well-crafted freight discrepancy report can pave the way for timely resolutions and maintain strong relationships with your shipping partners. Dive into our comprehensive guide and discover the essential elements of creating an effective report that gets results!

Date and Reference Number

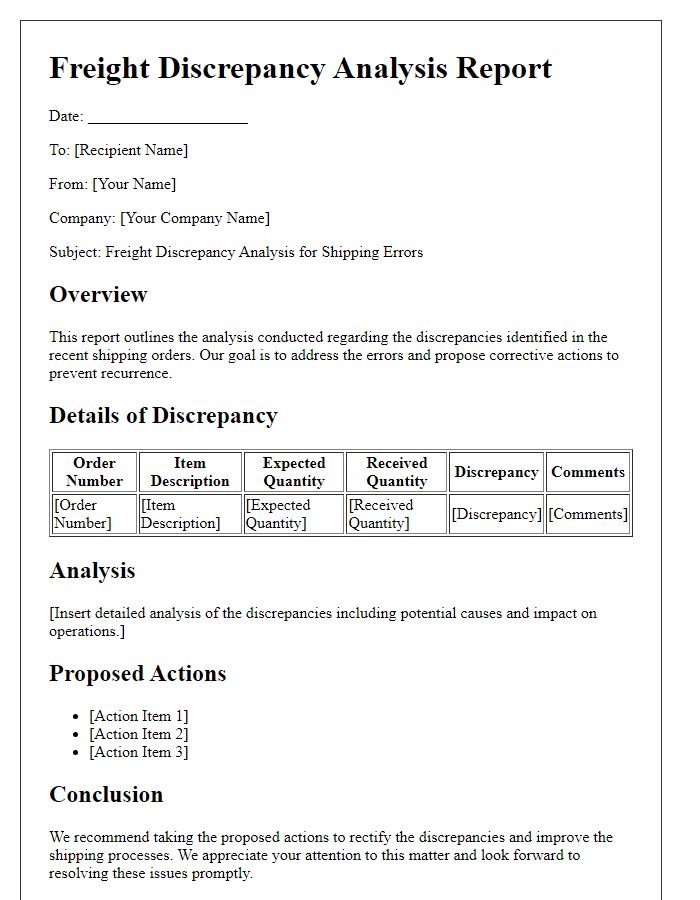

Freight discrepancy reports are essential for addressing issues related to shipments, such as lost or damaged goods. These reports typically include critical elements like date (indicating when the discrepancy was discovered), reference number (unique identifier for tracking), shipment details (description of goods, weight, and dimensions), carrier information (name of the logistics company), and specific nature of the discrepancy (shortage, overage, damage). Accurate reporting ensures timely resolution, maintaining relationship with suppliers or logistics partners, and preserving inventory accuracy. Meticulous documentation fosters trust and facilitates efficient corrective action while minimizing future discrepancies.

Sender and Receiver Details

When addressing a freight discrepancy report, it is essential to include accurate sender and receiver details. The sender's information should feature the company name, such as "ABC Logistics," along with the physical address, including street number, city, state, and postal code, demonstrating compliance with shipping regulations. Contact details, including a telephone number and email address for prompt communication, enhance the clarity of the report. For the receiver, include similar details, listing the recipient's company name, address, and contact information to avoid any delivery confusion. This comprehensive identification is crucial for resolving discrepancies effectively within the logistics process.

Detailed Description of Discrepancy

Freight discrepancies can cause significant logistical challenges and financial implications for businesses. Common issues include missing items, damaged goods, incorrect quantities, or shipment delays. A precise description of discrepancies is crucial. For instance, a shipment intended for the New York distribution center might contain 50 boxes of electronics but only 48 arrive due to a counting error during loading. Additionally, if one box displays visible damage, possibly from rough handling during transit, this further complicates inventory reconciliation. Documenting these discrepancies, including serial numbers, packing lists, and timestamps of delivery, ensures efficient resolution and future prevention of similar issues.

Supporting Documentation or Evidence

A freight discrepancy report outlines issues related to shipment inconsistencies, such as missing items or incorrect quantities. Supporting documentation plays a crucial role in substantiating claims regarding discrepancies, including delivery receipts, packing lists, and invoices. Photographic evidence (showing the condition of the package upon arrival) can highlight damages or shortages. Tracking numbers associated with shipments can help trace movements, pinpointing where mistakes occurred during transport. Copies of communication with carriers or freight forwarders further establish a timeline of events, enhancing clarity in resolutions. Each piece of evidence strengthens the case presented in the report.

Requested Action or Resolution Steps

Freight discrepancies can significantly impact logistical operations and financial outcomes. Recommended actions include conducting a thorough inventory audit, comparing shipping documents against received goods for accuracy. Documenting discrepancies meticulously aids in identifying systemic issues. Engaging with carriers such as FedEx or UPS to report discrepancies promptly ensures accountability. Utilizing tracking numbers helps trace shipment histories and facilitates resolution processes. Additionally, updating internal databases and communicating findings to stakeholders maintain transparency and enhance future shipping accuracy. Regular training for staff on handling freight discrepancies fosters a proactive response culture.

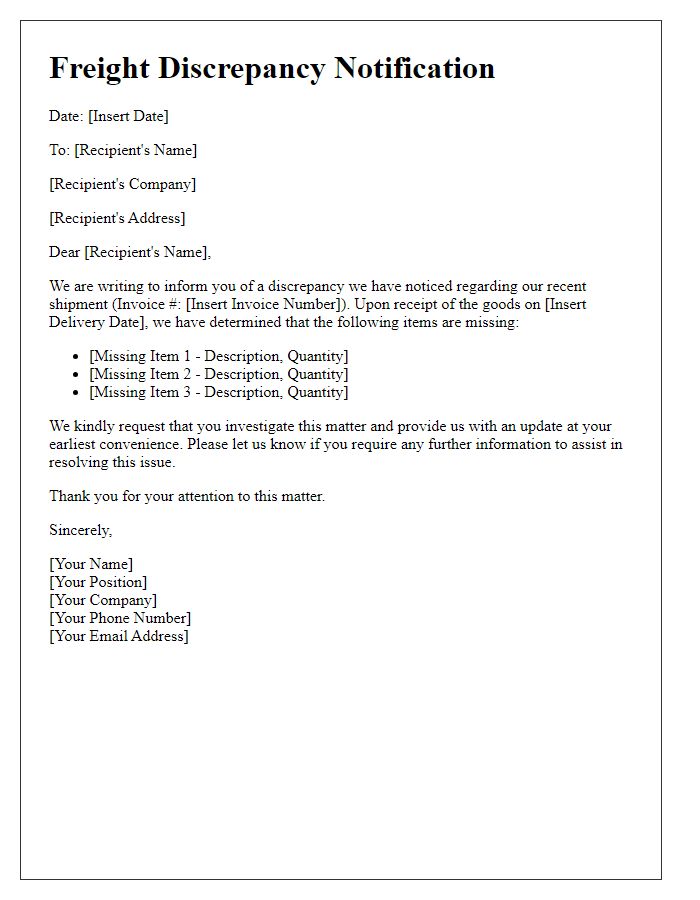

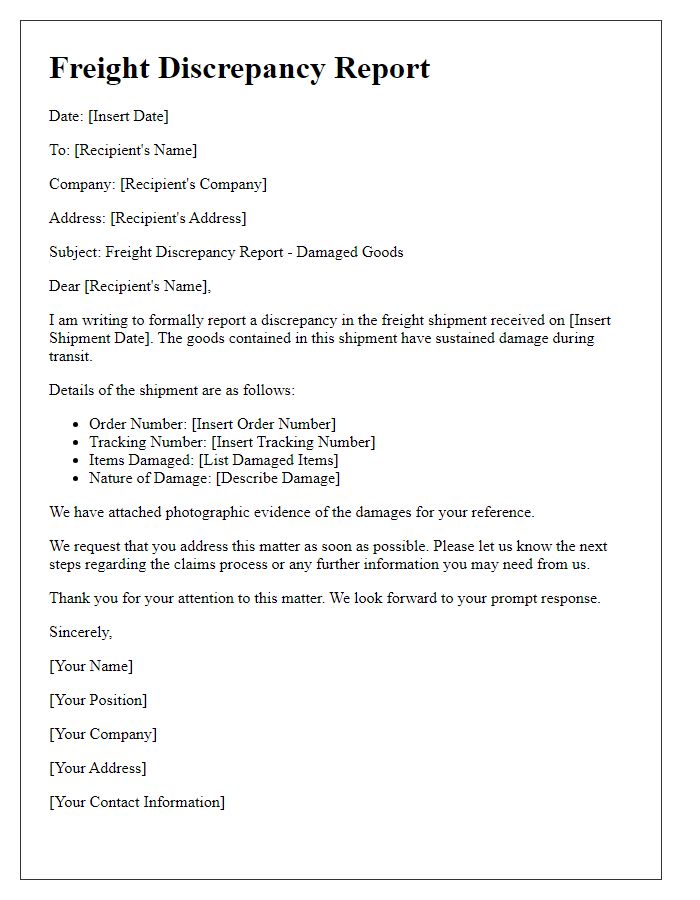

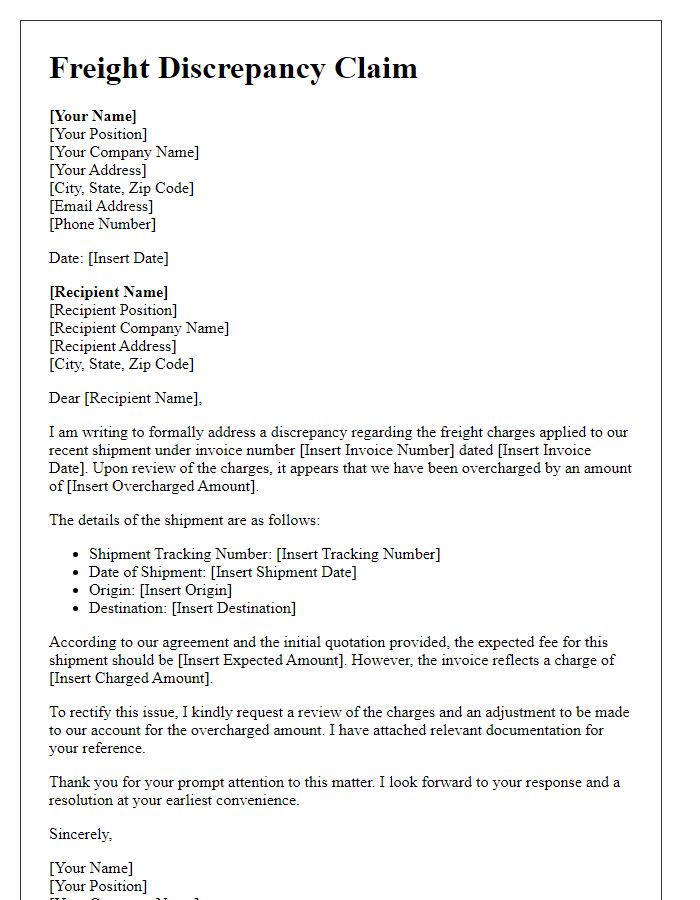

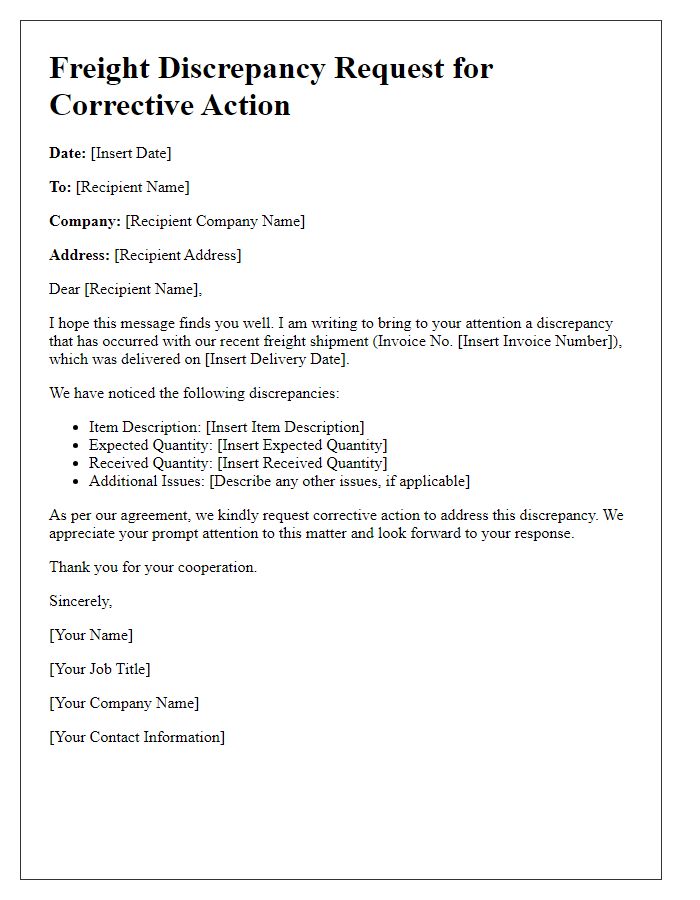

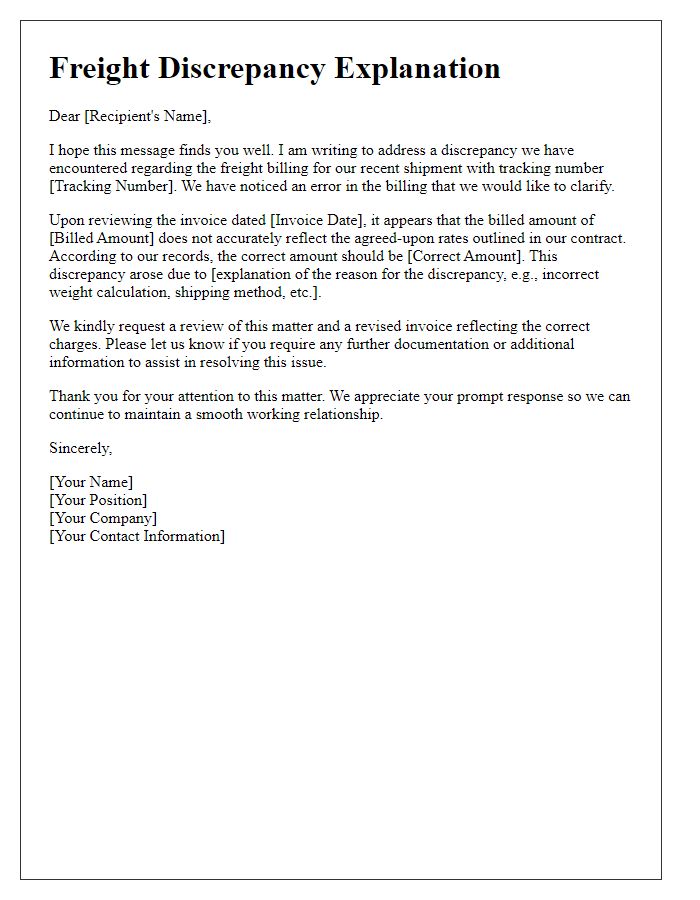

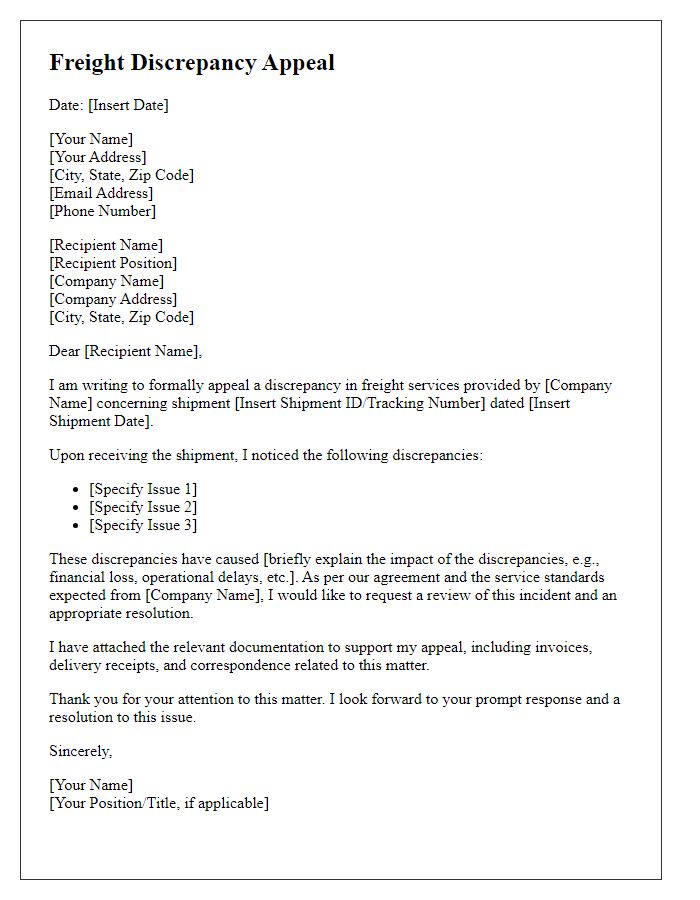

Letter Template For Freight Discrepancy Report Samples

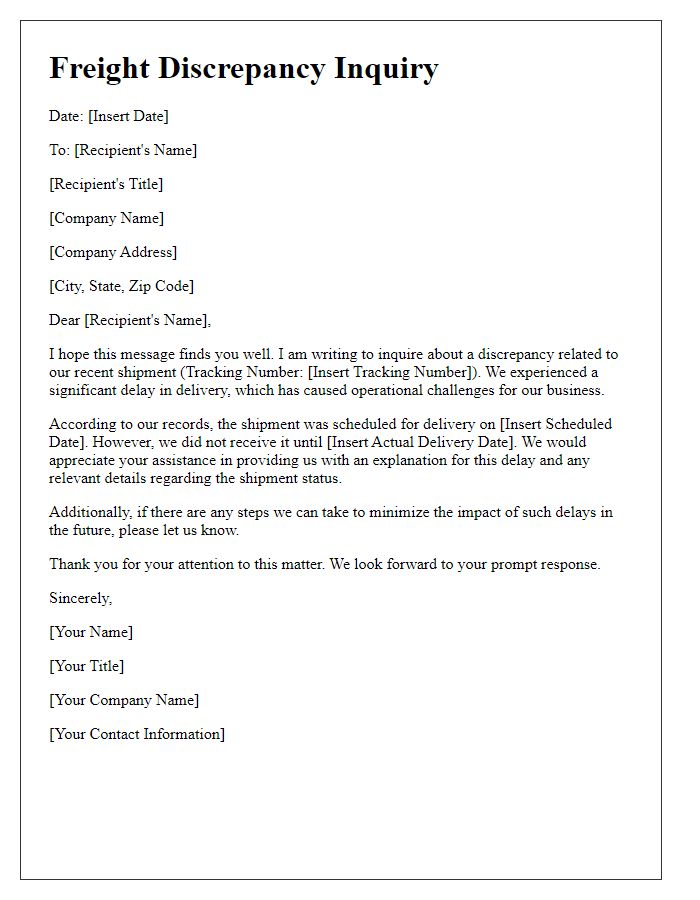

Letter template of freight discrepancy inquiry regarding delivery delays.

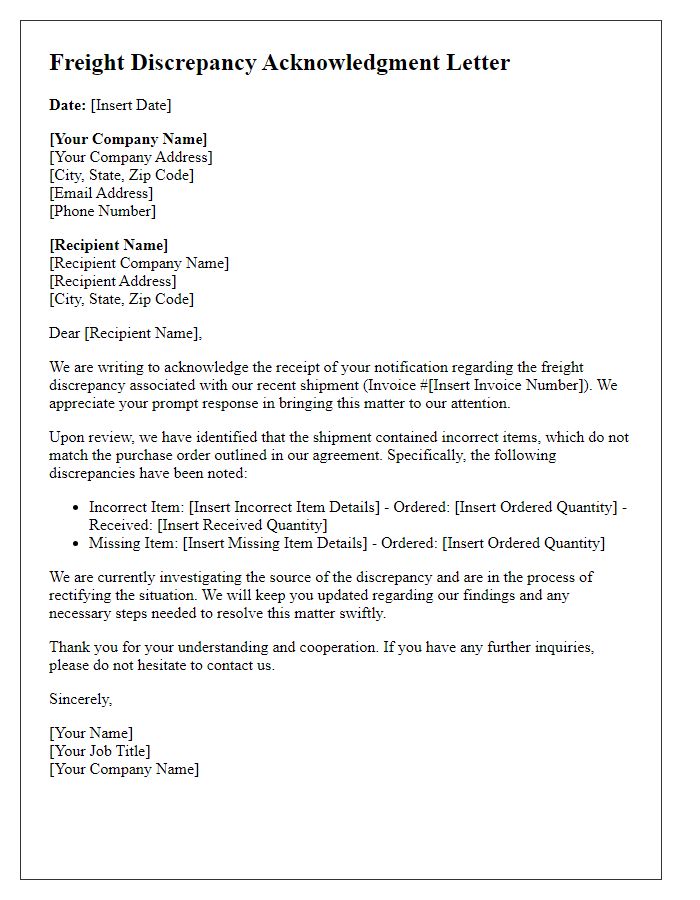

Letter template of freight discrepancy acknowledgment for incorrect shipments.

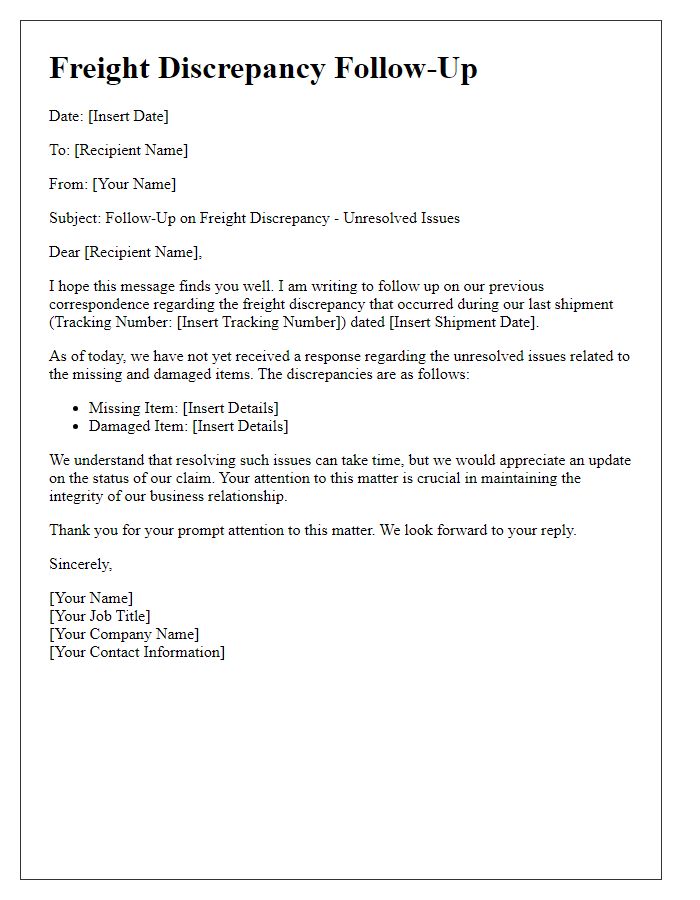

Letter template of freight discrepancy follow-up regarding unresolved issues.

Comments