Are you ready to streamline your supply chain and enhance efficiency through collaboration? In today's fast-paced logistics landscape, working together can lead to innovative solutions and significant cost savings for all parties involved. By fostering partnerships within the industry, we can transform challenges into opportunities for growth and success. Join us as we delve deeper into the benefits and strategies of collaborative logistics projectsâkeep reading to learn how you can get started!

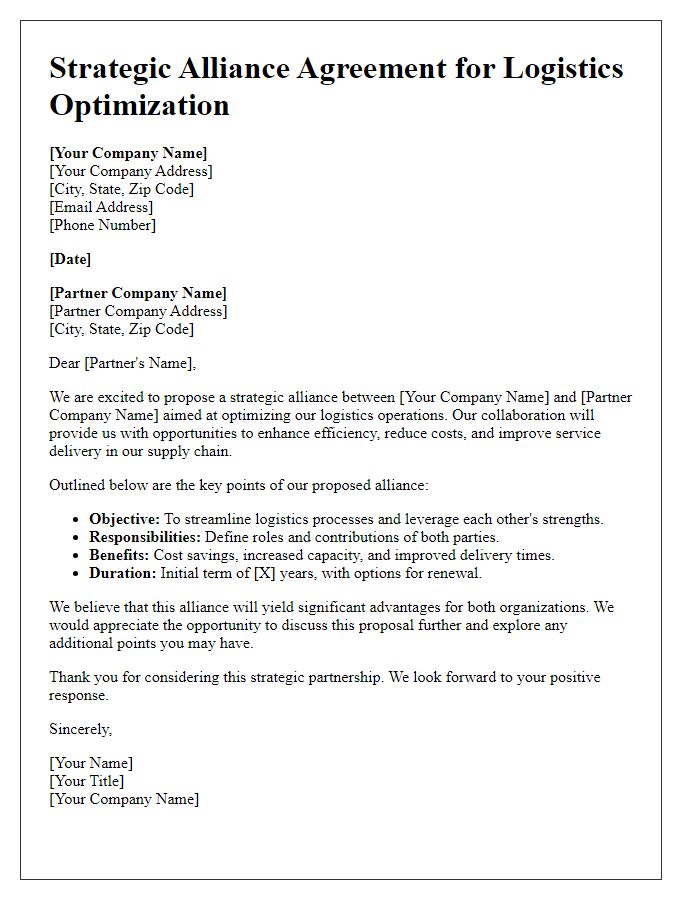

Project objectives and goals

The collaborative logistics project aims to enhance supply chain efficiency through increased inter-company cooperation and shared resources. Key objectives include reducing transportation costs by approximately 15% through optimized routing and joint shipment initiatives across regional hubs such as Chicago and San Francisco. Additionally, improving inventory turnover rates by 20% within six months can be achieved through real-time data sharing among partners, facilitating better demand forecasting. The project also targets a 30% reduction in delivery times by implementing advanced tracking technologies, enhancing customer satisfaction across diverse markets. Regular stakeholder workshops will ensure alignment and adaptability throughout the project's lifecycle, enabling continuous improvement in logistics performance.

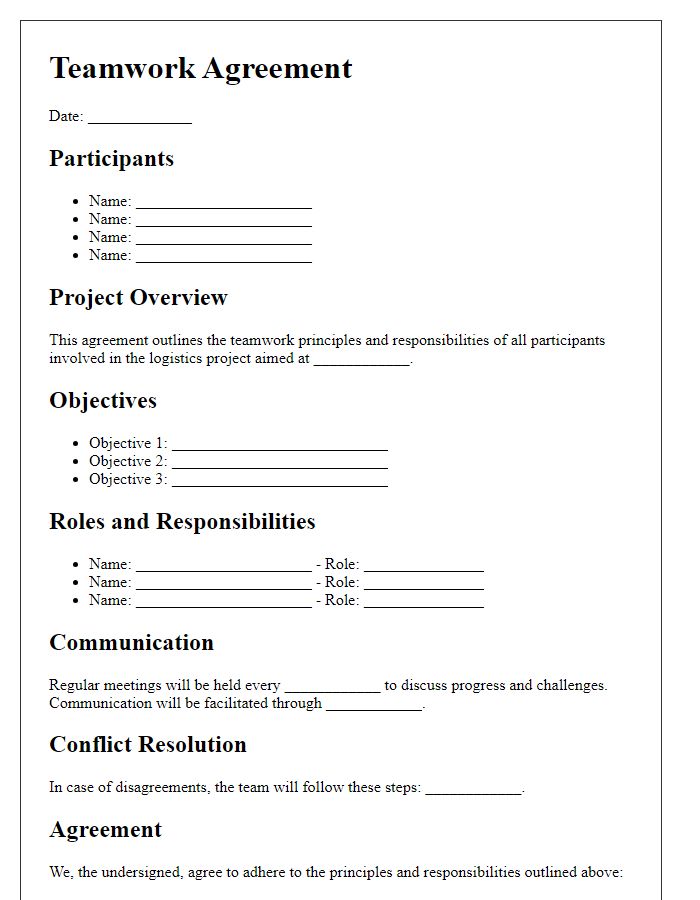

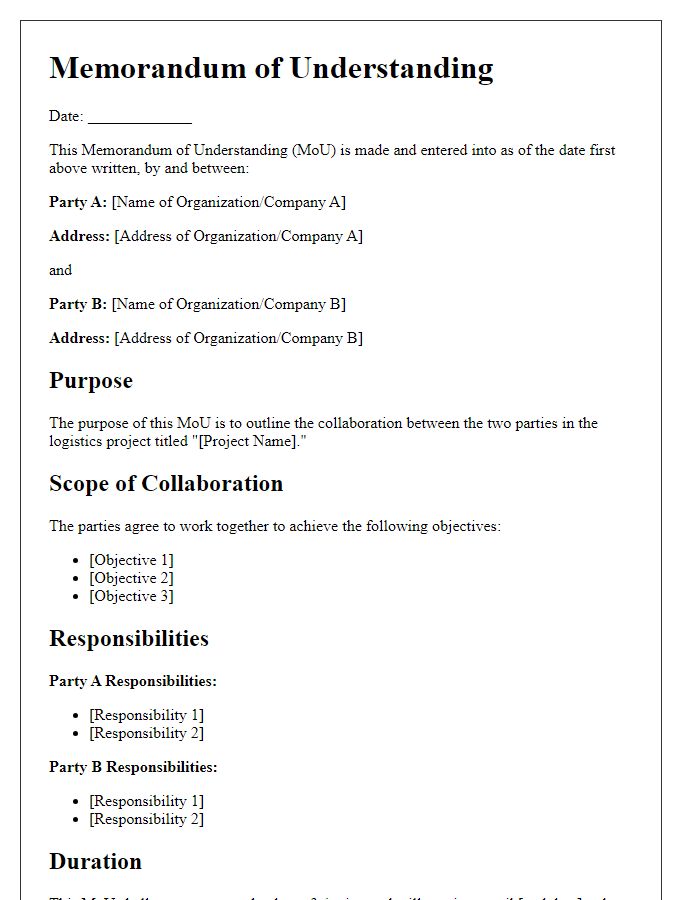

Scope of collaboration and responsibilities

In a collaborative logistics project, key areas for partnership include transportation management, warehousing solutions, and inventory control strategies. Participants, such as companies A and B, will delineate responsibilities for each segment of the supply chain. For instance, Company A may oversee the transportation of goods, ensuring timely delivery across regions, while Company B handles warehousing logistics, optimizing storage space for efficient operations at the distribution center located in Chicago. Additionally, both entities will share the responsibility for inventory management, utilizing integrated software exceeding 100 SKU (Stock Keeping Units) to streamline processes. Regular communication, scheduled weekly meetings, and performance metrics reporting will ensure alignment and accountability in achieving project goals.

Timelines and deadlines

In a collaborative logistics project, the establishment of clear timelines and deadlines is crucial for ensuring efficient operations and coordination among all parties involved. A project timeline typically includes critical milestones such as procurement stages, transportation schedules, and delivery dates, often tracked using software like Microsoft Project or Trello. For example, if a shipment is scheduled for delivery on March 15, 2024, all related tasks, such as customs clearance and loading, must be planned meticulously to prevent delays. Deadlines for each phase must be communicated effectively to stakeholders, including suppliers, carriers, and warehouse managers, enabling them to align their activities for seamless cooperation. Regular progress checks, perhaps on a bi-weekly basis, can help identify potential bottlenecks and facilitate timely interventions to meet project objectives.

Communication channels and coordination plans

Effective communication channels and coordination plans are vital for the success of collaborative logistics projects, such as those involving multiple stakeholders in global supply chains. Utilizing platforms like Slack (a messaging app for teams), Microsoft Teams (a collaboration tool for organizations), and Trello (a project management tool) can facilitate real-time communication among partners. Regular scheduled meetings, both virtual via Zoom (a leading video conferencing platform) and in-person, ensure alignment on project goals and progress updates. Establishing a centralized document repository, such as Google Drive or SharePoint, allows for easy access to critical project documentation, like timelines and resource allocations. Coordinating logistics through a shared calendar, like Google Calendar, helps avoid scheduling conflicts and ensures all stakeholders are on the same page regarding key milestones and deadlines, such as inventory restocks or shipment date reminders. Effective coordination ultimately streamlines operations, enhancing efficiency and reducing costs across all involved entities.

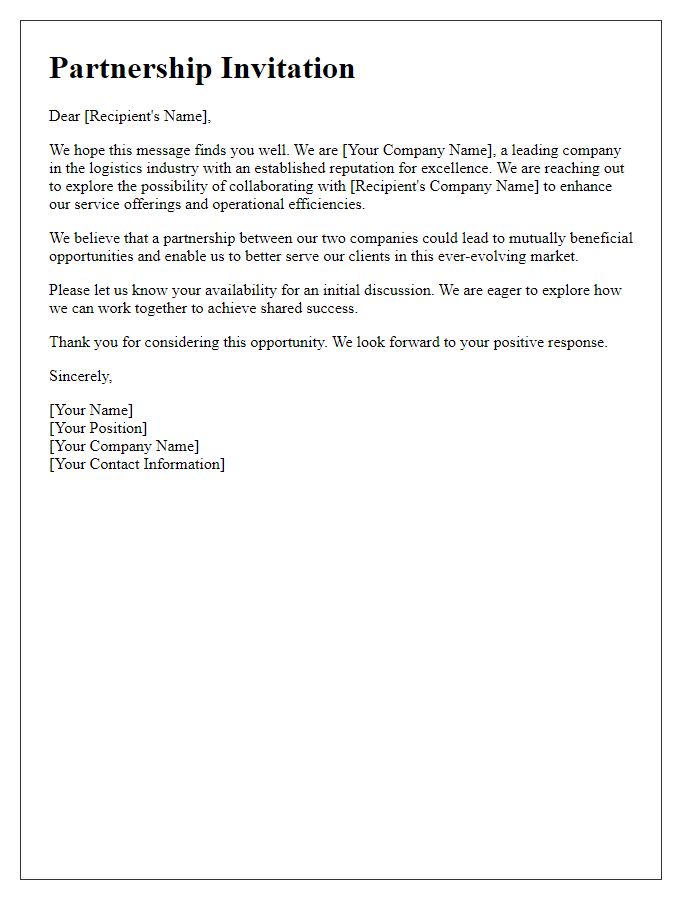

Partnership benefits and expected outcomes

A collaborative logistics project brings together multiple stakeholders, including transportation companies, warehouse providers, and technology firms, to enhance supply chain efficiency. By integrating resources, companies can reduce operational costs by an estimated 15-20% due to shared transportation routes and consolidated shipments. Enhanced visibility through digital platforms such as real-time tracking can lead to a 30% increase in customer satisfaction. Sustainability benefits arise from reduced carbon footprint, with potential reductions of over 25% in emissions, achieved through optimized routes and minimized empty miles. Additionally, participants can expect improved inventory turnover rates, with faster response times to market demands, fostering stronger partnerships and ultimately driving growth.

Comments