Are you looking to streamline your supplier reference process? In today's fast-paced business world, having a solid template can make all the difference in maintaining strong supplier relationships. By implementing a cohesive letter template, you can ensure consistency and professionalism in your communications. Let's dive deeper into how this can enhance your operations and strengthen your partnerships!

Company Information and Background

Supplier reference implementation provides essential details about corporate structure, operational reach, and market presence. This document typically includes the name of the supplier, foundational year, and location of headquarters, which could be Silicon Valley, California. It may also outline key services or products offered, such as innovative technology solutions or sustainable materials, emphasizing their relevance to current industry trends. Additionally, noteworthy partnerships with organizations like Microsoft or Google can demonstrate credibility within the technological landscape. Financial metrics, including yearly revenue (which could exceed $50 million), and growth rates should be highlighted to illustrate stability and industry confidence. Lastly, mentioning certifications like ISO 9001 can validate their quality management systems.

Relationship and Engagement Details

Supplier relationship management plays a critical role in ensuring seamless operations within organizations. Effective communication fosters strong partnerships, enhancing collaboration and trust. Regular engagement activities, including quarterly business reviews and feedback sessions, help identify improvement areas. Platforms, such as Supplier Portal, streamline document sharing and real-time updates, improving transparency. Metrics, including on-time delivery rates and quality compliance percentages, provide insights into supplier performance, guiding strategic decisions. Annual contracts, often renegotiated, outline expectations and strengthen commitment. Proactive engagement not only mitigates potential issues but also drives innovation, ultimately benefiting both parties in the supply chain ecosystem.

Performance and Quality Assessment

Performance evaluation metrics are critical for assessing supplier reliability and product quality. Establishing criteria involves quantitative measures such as defect rates, delivery timelines, and compliance with industry standards. For instance, a defect rate below 1% may be expected for electronic components supplied to automotive manufacturers, where safety and performance are paramount. Additionally, the delivery timeline should not exceed 2 days for urgent orders from suppliers located in proximity to manufacturing facilities, such as those in Shenzhen, China. Implementing regular quality audits and utilizing feedback mechanisms enhances transparency and fosters continuous improvement. Technology adoption, such as integration of automated supply chain software, plays a pivotal role in streamlining processes and ensuring real-time tracking of shipments and inventory levels, ultimately driving enhanced supplier performance and customer satisfaction.

Communication and Support Evaluation

Supplier performance evaluation plays a critical role in ensuring effective communication and support processes between businesses and their suppliers. Organizations often conduct assessments based on key metrics such as response time (average time taken to address inquiries, typically within 24 hours), clarity of information provided (evaluated through feedback scores, usually on a scale of 1 to 5), and issue resolution effectiveness (percentage resolved on the first contact, ideally above 85%). Additionally, regular training sessions (monthly in-depth workshops) can enhance supplier understanding of operational standards and expectations. Demand for responsive support systems reflects in customer satisfaction metrics (customer satisfaction scores, ideally above 90%). By maintaining a structured communication framework, organizations can foster deeper partnerships and drive mutual growth.

Future Collaboration and Potential Growth

Future collaboration between companies often hinges on identifying mutual goals and exploring avenues for potential growth. By leveraging combined resources, organizations can innovate and develop products that meet emerging market demands. This collaboration could take place in areas such as supply chain optimization, which significantly boosts efficiency and reduces costs. Additionally, joint investments in research and development can lead to pioneering technologies, enhancing competitive advantage. Stakeholders should consider integrating their expertise and networks, as demonstrated by successful partnerships in sectors like technology and manufacturing, where shared insights have accelerated progress. Establishing clear communication channels and aligning strategies can pave the way for sustained growth and long-term success in a competitive marketplace.

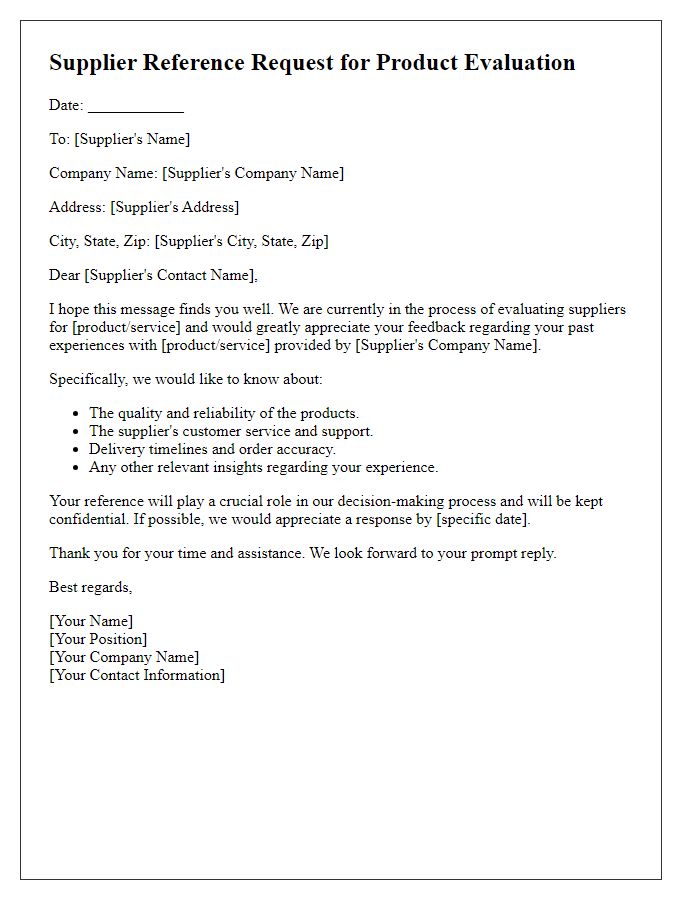

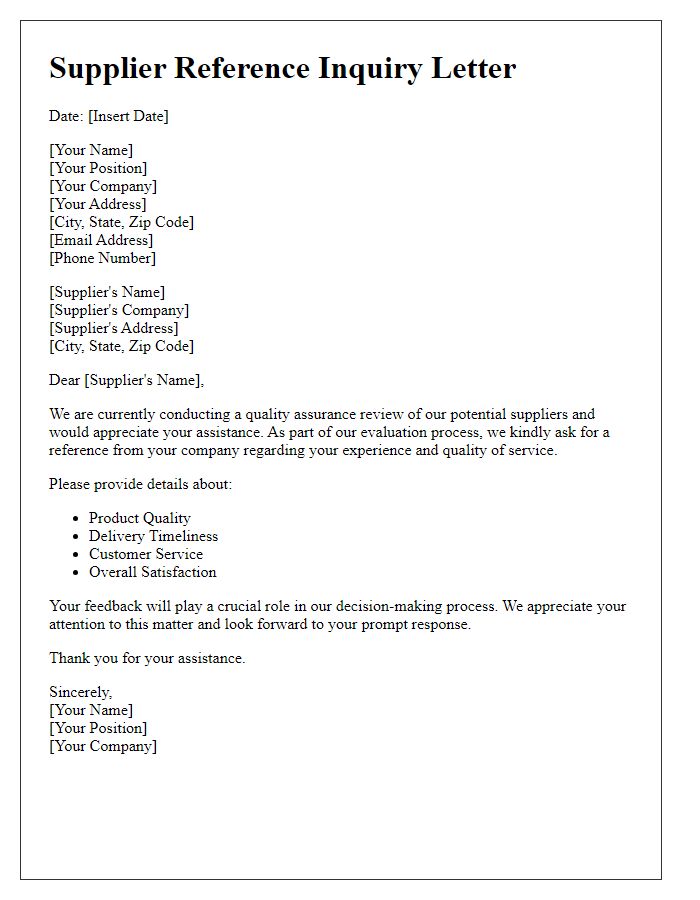

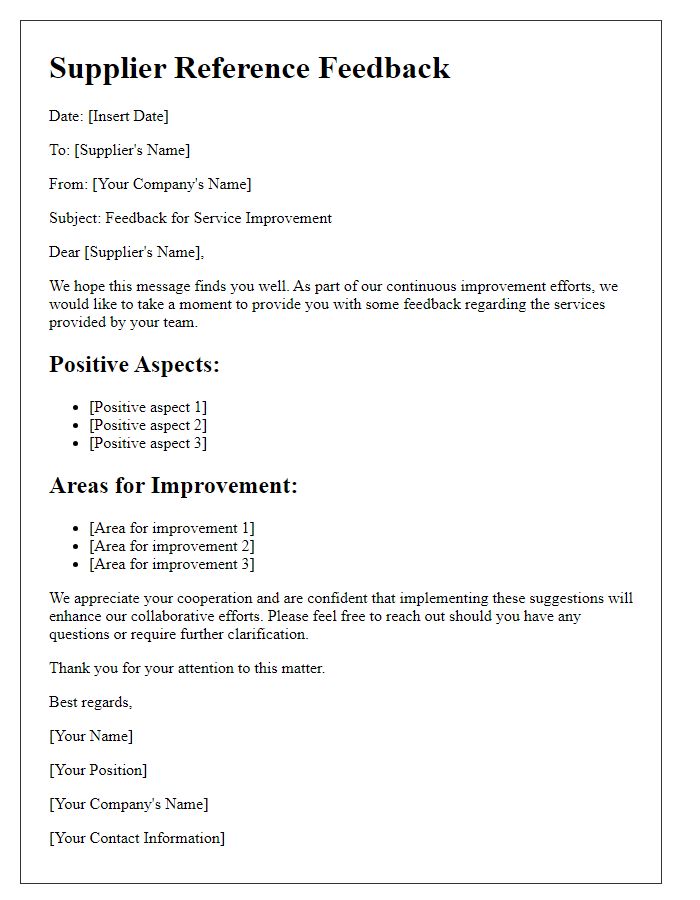

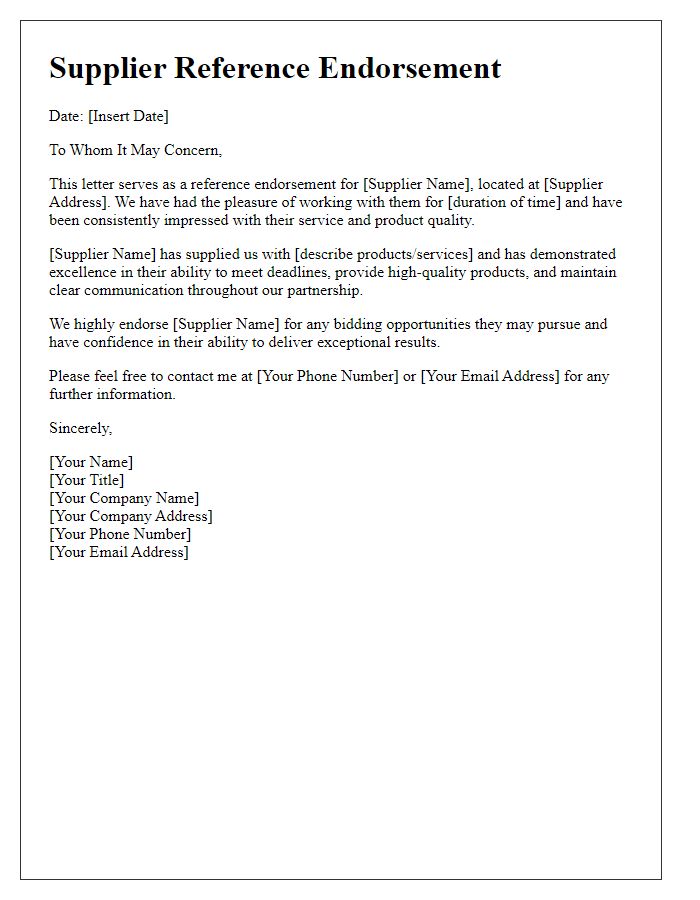

Letter Template For Supplier Reference Implementation Samples

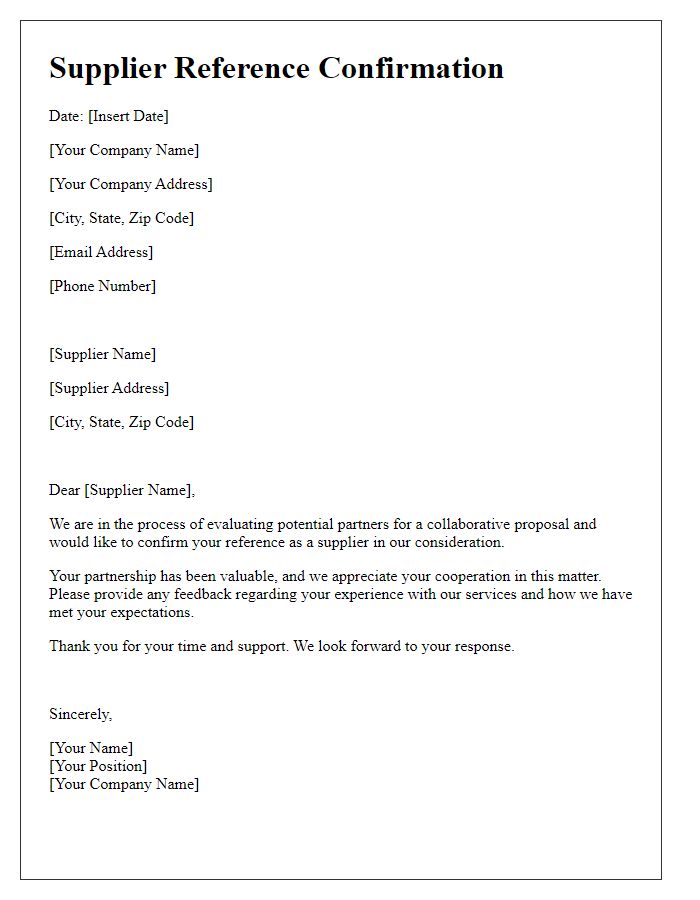

Letter template of supplier reference confirmation for partnership proposal.

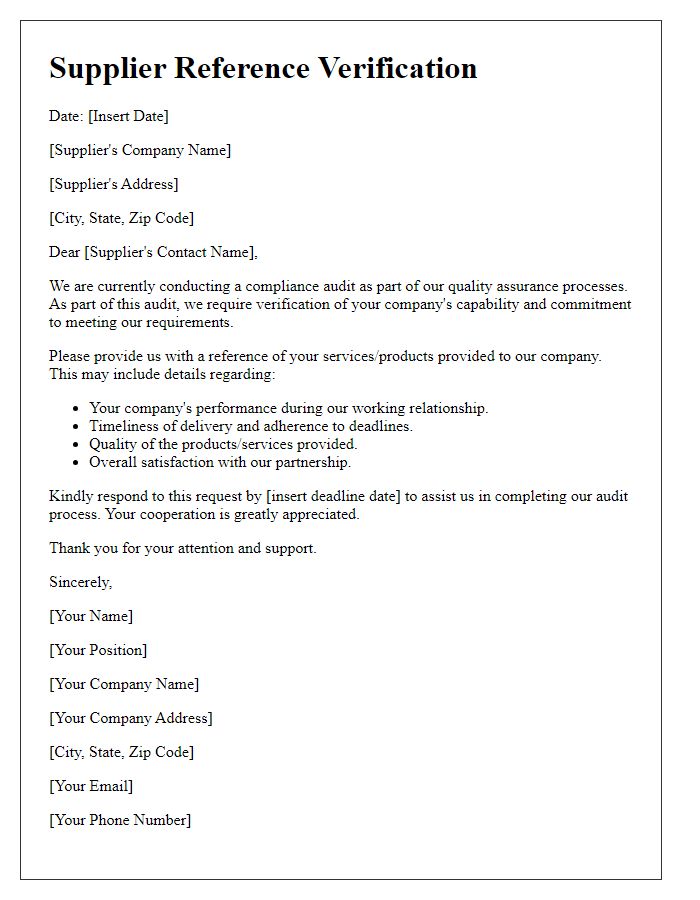

Letter template of supplier reference verification for compliance audit.

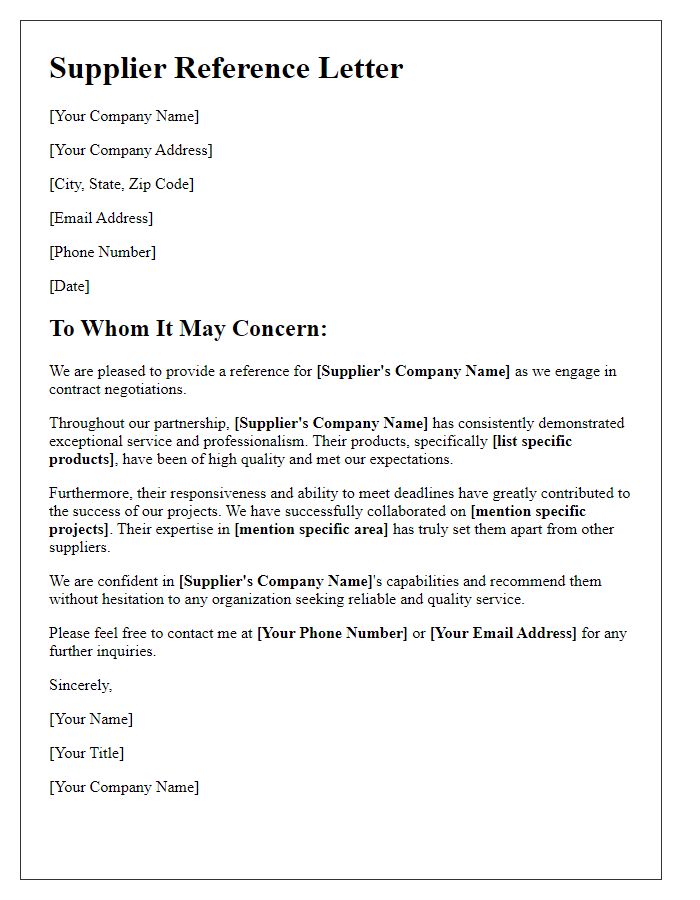

Letter template of supplier reference documentation for contract negotiation.

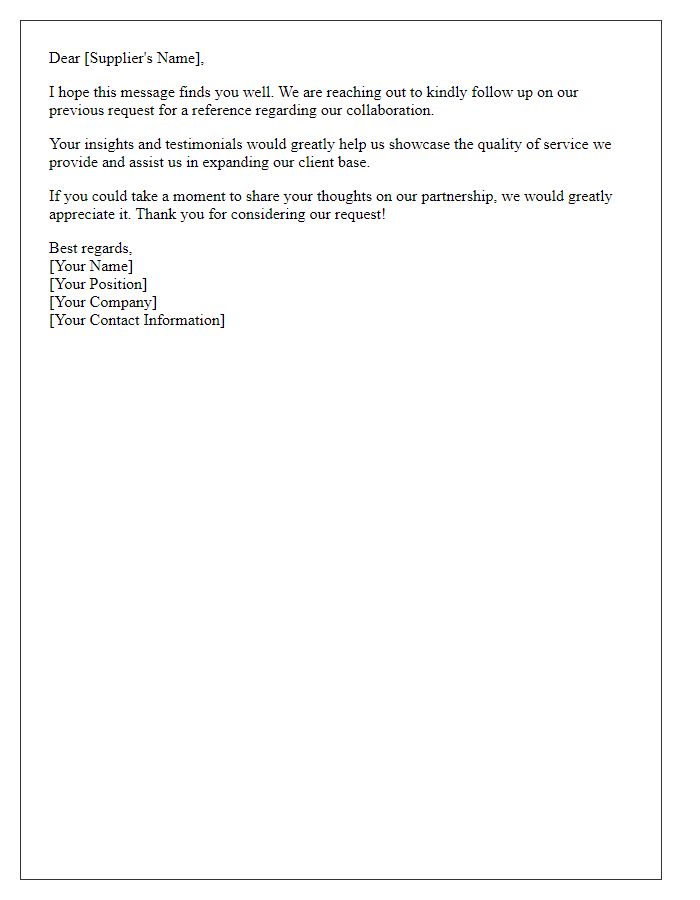

Letter template of supplier reference follow-up for client testimonials.

Comments