Are you navigating the tricky waters of supplier disputes? It can be challenging to address conflicts while maintaining professional relationships, but having a well-structured letter template can simplify the process. This guide will help you communicate your concerns clearly, ensuring both parties can work towards a resolution. Ready to dive into the details and become an expert in supplier dispute resolution?

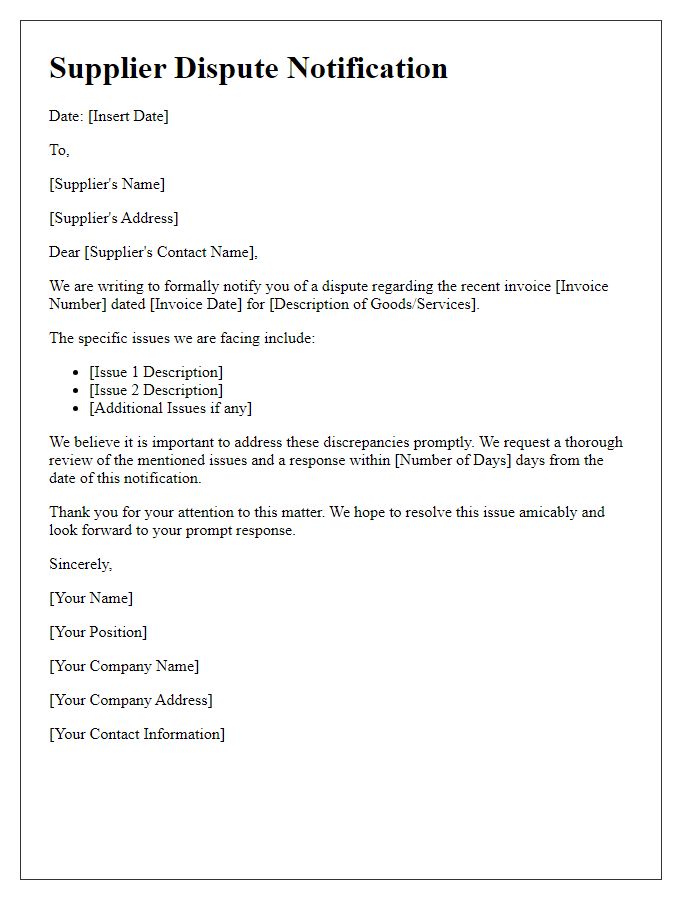

Clarity of Issue Description

In the context of supplier dispute resolution processes, clarity of issue description is paramount. A clearly articulated issue facilitates effective communication between the parties involved in the dispute, such as the purchasing department and the supplier, ensuring that misunderstandings are minimized. For example, when a defect in a batch of 500 items from Supplier A is reported, specifying the exact nature of the defect, such as a 10% failure rate in product functionality, aids in identifying whether the supplier's quality control processes comply with standards. Precise references to clauses in the purchase agreement, such as the acceptance criteria outlined in Section 7, provide a legal framework for discussions. Additionally, including supporting documents, such as failure reports generated on October 10, 2023, from the quality assurance team, enhances credibility and aids in accurate resolution. Thus, the clarity of the issue description not only addresses the immediate concern but also establishes a foundation for future business relations.

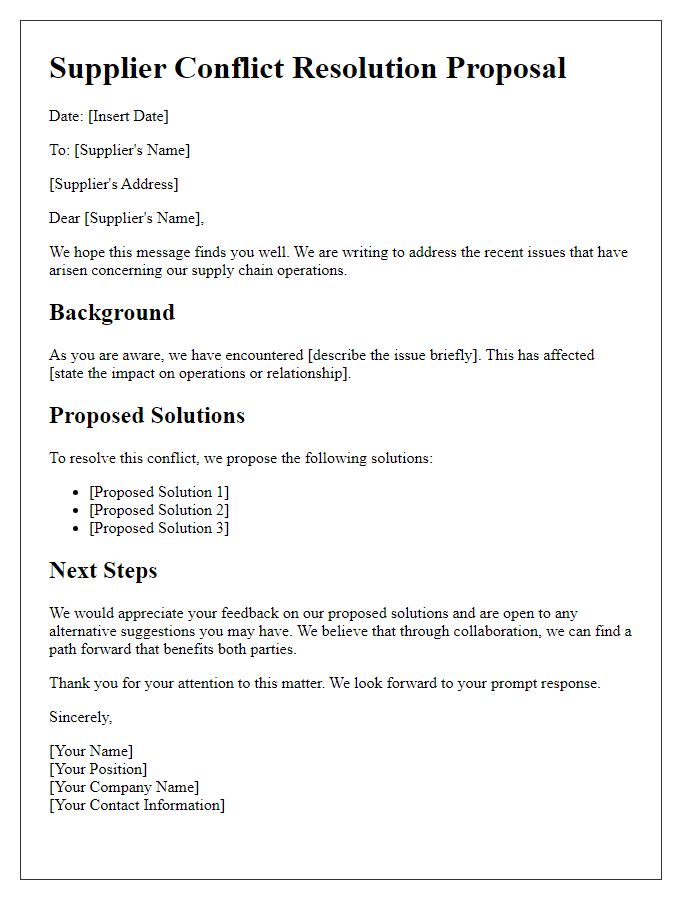

Specific Desired Outcomes

Achieving effective resolution in supplier disputes involves clearly defined desired outcomes. Common goals include timely delivery of goods, increased quality standards, and improved communication protocols. Specific outcomes might entail the establishment of a revised shipment schedule that adheres to agreed timelines, ensuring that product quality meets or exceeds industry standards, and instituting regular check-in meetings (monthly or quarterly) to facilitate ongoing dialogue. Additionally, implementing measurable performance metrics (such as on-time delivery rates above 95% and defect rates below 2%) can enhance accountability and foster a stronger partnership moving forward.

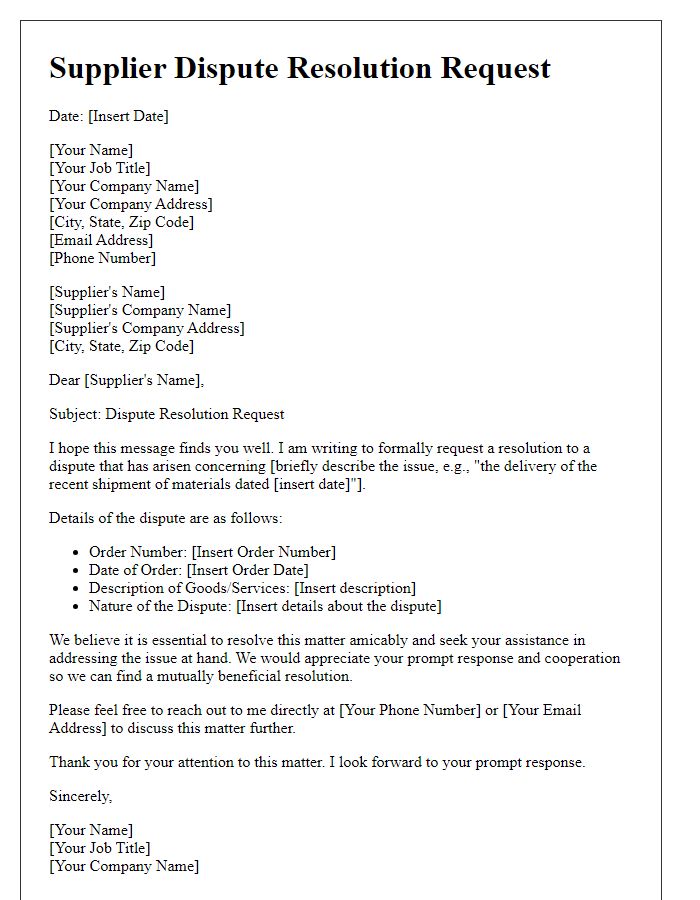

Supplier Contact Details

Supplier contact details are crucial for effective communication during a dispute resolution process. Key elements include the supplier's name (e.g., ABC Manufacturing), address (e.g., 123 Industry Lane, Springfield, IL, USA), telephone number (e.g., +1-555-0123), and email address (e.g., contact@abcmfg.com). Additional identifiers such as the supplier's account number or reference ID can facilitate quicker reference during interactions. Gathering and organizing this information ensures that all parties involved in the dispute, including procurement managers and legal representatives, can reach out promptly to address concerns or negotiate terms effectively. Ensuring accuracy in these details minimizes delays and enhances the resolution process.

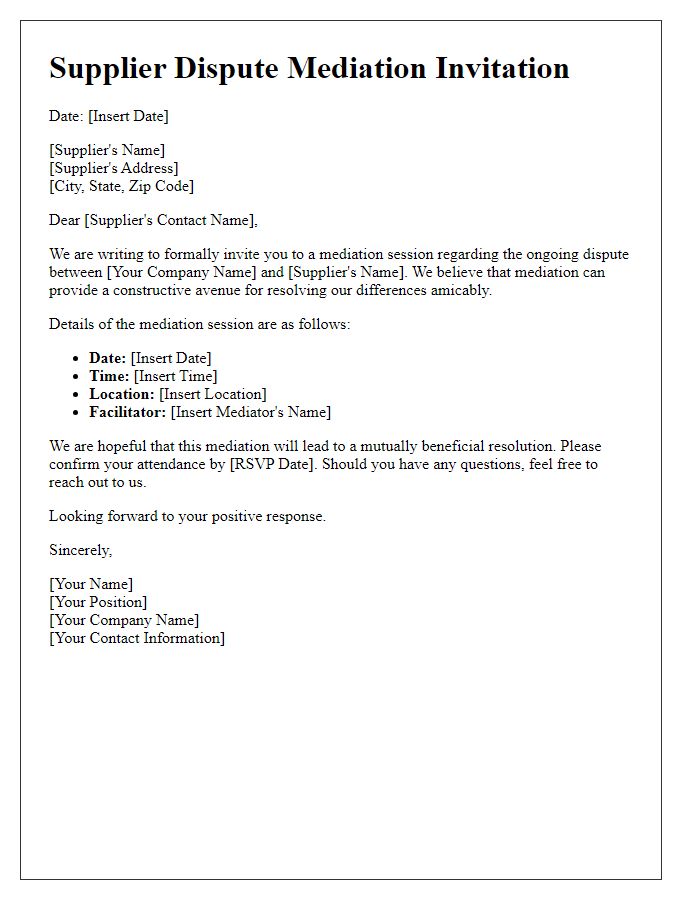

Timeline for Response

The timeline for response during the supplier dispute resolution process is crucial in ensuring a relatively smooth resolution. Initial acknowledgment of the dispute should occur within three business days, allowing the aggrieved party to confirm receipt of the complaint. Following this acknowledgment, a detailed review of the complaint by the supplier must occur within seven business days, involving consultation with relevant departments, including quality control and finance. A formal response should be issued by the supplier within 15 business days, outlining proposed resolutions or requests for further clarification. Should the resolution not be finalized at this juncture, a mediation session should be scheduled within 30 days. If disputes persist beyond mediation, either party may escalate the issue to arbitration for a binding resolution within 60 days from the initial complaint. Timely communication and documentation are essential throughout all stages to ensure transparency and accountability.

Documentation and Evidence

The supplier dispute resolution process involves meticulous documentation and robust evidence collection. Essential documents include contracts outlining terms agreed upon in the initial negotiation stages, such as pricing agreements or delivery schedules, which are crucial for assessing the scope of the dispute. Invoices from recent transactions, dated within the last quarter, can provide concrete evidence of financial obligations and discrepancies. Email correspondence (e.g., timestamps from communication exchanges) is vital to demonstrate attempts made to resolve issues. Additionally, photographs or inspection reports (generated by quality assurance teams) documenting product quality or delivery anomalies substantiate claims made during the dispute. Collectively, this compilation of evidence forms the backbone of a successful resolution strategy, ensuring transparency and facilitating a fair assessment of the situation.

Comments