Hey there! As we continue to streamline our operations, it's important to keep you informed about any changes to our supplier delivery schedule. We understand that timely deliveries are crucial for your planning and production, so we want to ensure you have the latest updates. Curious about how these changes might affect your orders? Keep reading to find out more!

Clear and Concise Language

Timely updates regarding supplier delivery schedules are essential for maintaining operational efficiency in supply chain management. Frequent delays may arise due to unforeseen circumstances. Recent reports indicate that North American suppliers, especially those in the automotive sector, are experiencing a 15% increase in lead times due to labor shortages and global shipping constraints. These delays can lead to inventory shortages and increased costs for manufacturers. For optimal planning, accurate communication of revised dates is crucial. Industry best practices suggest sending updates at least one week in advance of expected delivery changes to allow adequate response time.

Accurate Delivery Timeline

An accurate delivery timeline is essential for maintaining smooth supply chain operations. A well-defined schedule helps manage inventory levels at distribution centers and retailers. Suppliers must provide timely updates on shipment status, including departure dates from manufacturing sites and estimated arrival times at warehouses. Delays can significantly impact the production line efficiency and customer satisfaction levels. For example, a delay of just one week can lead to stockouts, affecting sales performance and potentially resulting in lost revenue. Adhering to agreed-upon delivery dates fosters strong partnerships between manufacturers and suppliers, ensuring timely project completions and optimal service delivery.

Include Detailed Order Information

A supplier delivery schedule update is crucial for effective supply chain management. The detailed order information includes specific product quantities, item descriptions, and order numbers. For instance, an order consisting of 500 units of high-grade steel rods (Order No. 12345) scheduled for delivery to Milwaukee, Wisconsin on April 10, 2024 should be outlined precisely. Additionally, any changes to previous agreed terms, such as arrival times or delivery methods (e.g., standard freight or expedited shipping), must be addressed. Compliance with quality standards set forth by ISO 9001 should also be confirmed to maintain product integrity upon arrival.

Contact Information for Queries

A supplier delivery schedule update typically includes crucial details about logistics, timelines, and communication channels. Updated schedules may reveal shifts in anticipated delivery dates for materials including raw materials or components necessary for production. Suppliers must provide reliable contact information for queries; this might include direct phone numbers or emails for account managers. Effective communication can mitigate potential disruptions in the supply chain and ensure timely updates about delays or changes in shipment destinations. Accurate record-keeping of all contact details is essential for efficient handling of issues that may arise during the delivery process.

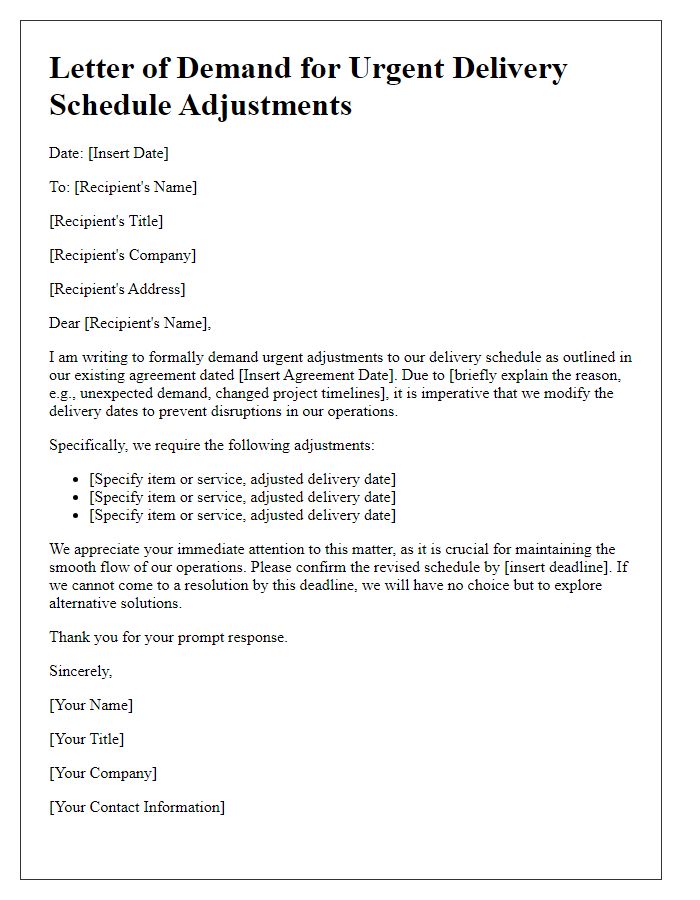

Formal and Professional Tone

The delivery schedule for the upcoming shipment of high-quality raw materials, such as steel and plastics, from supplier XYZ Corp has been revised. As per the latest communication received on April 15, 2023, the new expected delivery date is now set for May 5, 2023. Delays have been attributed to ongoing supply chain disruptions affecting transportation logistics in major ports, specifically in Los Angeles, where congestion has increased significantly. Accurate tracking numbers will be provided to ensure timely updates and facilitate efficient inventory management for our production lines. Please ensure your teams are prepared for the updated schedule to maintain a seamless workflow.

Letter Template For Supplier Delivery Schedule Update Samples

Letter template of inquiry regarding changes in delivery dates from supplier

Letter template of notification for revised delivery timelines from supplier

Letter template of confirmation of updated delivery schedule with supplier

Letter template of apology for delivery delays and request for new schedule

Letter template of clarification request for delivery schedule discrepancies

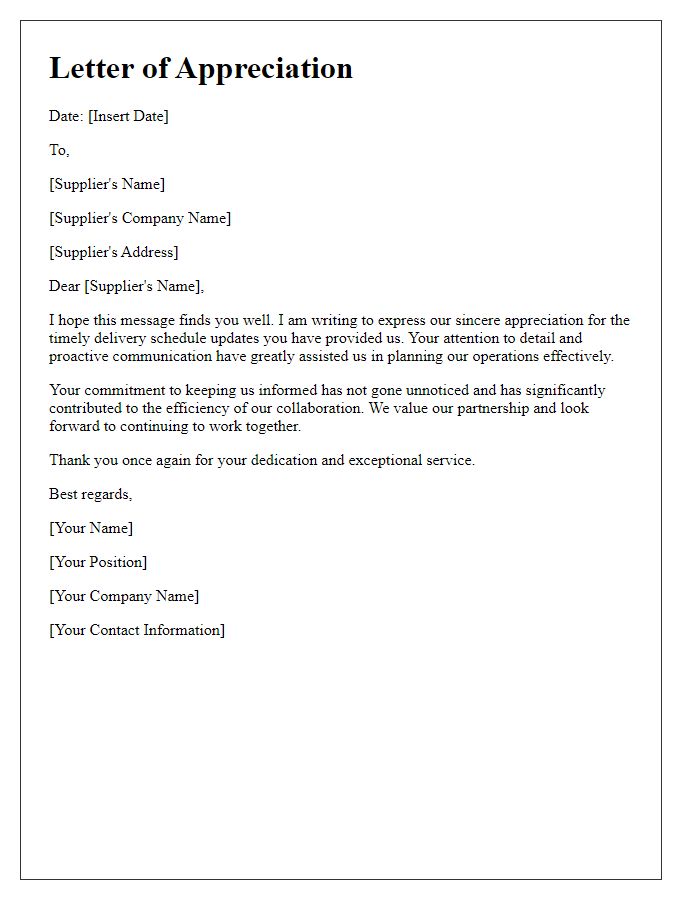

Letter template of feedback on delivery schedule efficiency from supplier

Comments