Are you a subcontractor looking to enhance your safety compliance? Understanding the importance of strict safety protocols is crucial for both protecting your team and maintaining project efficiency. In this article, we'll explore essential strategies and tools to ensure you not only meet safety regulations but also foster a culture of accountability on the job site. Join us as we dive deeper into effective compliance measures that can benefit your operations.

Introduction and Purpose

The subcontractor safety compliance program aims to ensure adherence to occupational health and safety regulations across all construction sites within the jurisdiction, such as the Occupational Safety and Health Administration (OSHA) standards. By implementing rigorous safety protocols, this initiative seeks to minimize workplace hazards and promote a culture of safety among subcontractors involved in large-scale projects, such as the downtown high-rise development in Chicago. Compliance includes regular safety training sessions, mandatory reporting of incidents, and adherence to specific safety protocols relevant to high-risk activities, such as scaffolding installation and electrical work. The ultimate goal is to establish a safer working environment, reducing injury rates and ensuring the well-being of all personnel involved in the construction process.

Safety Compliance Requirements

Subcontractors in the construction industry must adhere to strict safety compliance regulations to ensure a secure work environment. OSHA (Occupational Safety and Health Administration) standards mandate specific protocols, including the use of personal protective equipment (PPE) such as hard hats, safety goggles, and high-visibility vests on job sites. Frequent safety training sessions, typically held quarterly, aim to educate workers on hazard recognition, emergency response procedures, and proper equipment handling to mitigate risks associated with working at heights or near heavy machinery. In addition, subcontractors must maintain documentation of safety inspections for equipment used, which must comply with manufacturer guidelines and local building codes within their jurisdiction, such as those established by the International Code Council (ICC). Regular audits and on-site inspections, conducted biannually by the primary contractor or a safety officer, are essential to ensure continuous adherence to safety standards and to identify areas needing improvement.

Documentation and Reporting Obligations

Subcontractor safety compliance involves rigorous documentation and reporting obligations to ensure workplace safety. Safety manuals need to be developed, specifying safety policies and procedures relevant to the specific construction project registered at the Occupational Safety and Health Administration (OSHA). Daily safety checklists must be maintained, documenting observations and actions taken, especially at construction sites located in high-risk areas like downtown urban zones. Weekly safety reports should summarize incidents, injuries, and near misses, utilizing incident reporting forms compliant with ANSI Z16 standards. Compliance audits will be conducted quarterly, requiring subcontractors to show documented training records for all employees, reflecting certifications such as OSHA 10 or OSHA 30, and ensuring each worker has completed necessary safety orientation sessions. All incidents must be reported to the primary contractor within 24 hours, emphasizing communication efforts in maintaining an injury-free environment, thereby enhancing overall site safety culture.

Communication and Incident Reporting Protocols

Subcontractors must adhere to stringent safety compliance measures to ensure a safe working environment on construction sites. Established protocols include a mandatory communication system for reporting safety incidents, which requires immediate notification to site supervisors upon any accident or near-miss events involving personnel or equipment. Documentation of these incidents is essential, ensuring accurate records of occurrences for future analysis and prevention strategies. Regular safety briefings, scheduled weekly, emphasize the importance of reporting and reviewing incidents to foster a culture of safety across all teams engaged in high-risk tasks. Compliance with these protocols will significantly enhance overall safety and operational efficiency in accordance with Occupational Safety and Health Administration (OSHA) standards.

Penalties and Consequences for Non-compliance

Non-compliance with safety regulations can lead to significant penalties for subcontractors in construction projects. Violations of Occupational Safety and Health Administration (OSHA) standards may incur fines, reaching up to $13,653 per serious violation, as established in 2023. Repeated infractions could elevate penalties to a maximum of $136,532, reflecting the severity of neglecting worker safety. Consequences extend beyond financial repercussions, including potential suspension from future contracts in major construction hubs like New York City and Los Angeles, harming reputational standing within the industry. Legal ramifications may also arise, involving lawsuits or liability claims if non-compliance leads to workplace injuries or fatalities, underscoring the critical importance of adherence to safety protocols at all times.

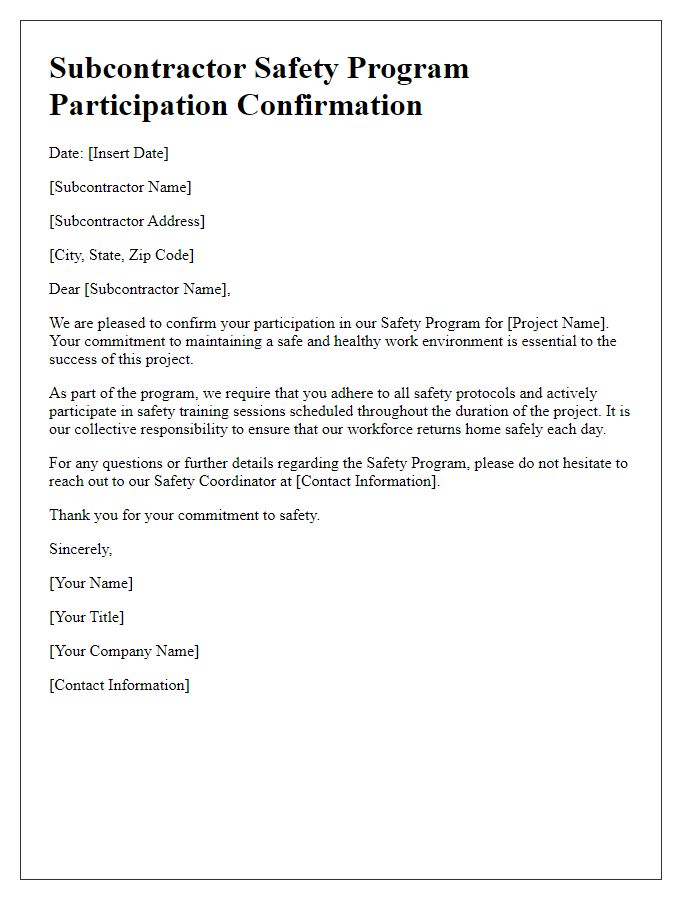

Letter Template For Subcontractor Safety Compliance Samples

Letter template of safety compliance documentation request for subcontractors

Comments