Are you struggling with the intricacies of shipping inventory reconciliation? You're not alone! Many businesses face challenges in ensuring their stock levels align with shipping records, but understanding the process can make all the difference. Join us as we delve into strategies and tips to simplify your inventory reconciliation, helping you achieve greater accuracy and efficiencyâread on to discover more!

Date and Contact Information

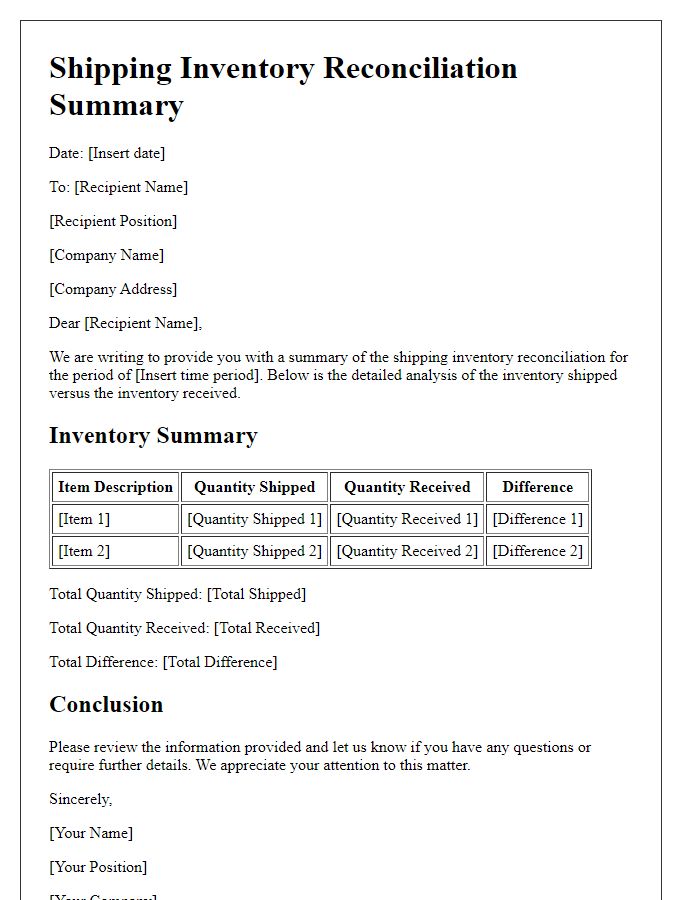

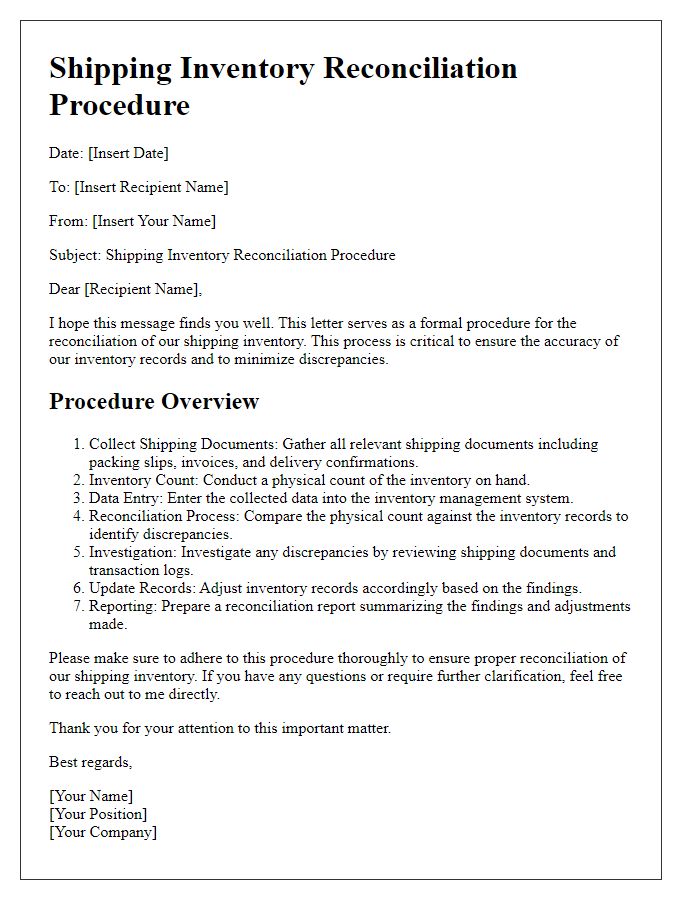

The shipping inventory reconciliation process plays a crucial role in maintaining accurate records throughout the supply chain. Accurate reconciliation involves verifying quantities against shipping documents (such as bills of lading) and physical inventory counts within warehouses. Discrepancies may arise due to various factors, including shipment delays, losses during transit, or improper documentation. Implementing a systematic approach, utilizing software for tracking shipments and inventory levels, enhances accuracy. Regular audits, ideally conducted monthly, ensure that variances are addressed promptly, fostering better relationships with suppliers and ensuring compliance with financial reporting standards.

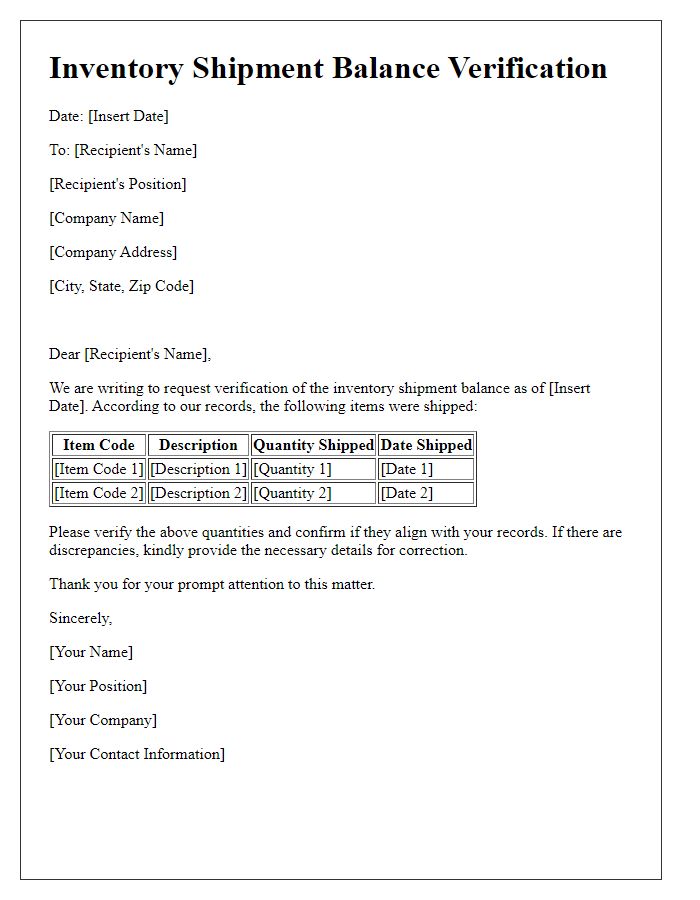

Inventory Discrepancy Details

Inventory reconciliation is essential for maintaining accurate stock levels in warehouses, particularly during shipping processes. Discrepancies can arise from various sources such as human error, inventory shrinkage, or data entry mistakes. For instance, a warehouse located in Houston, Texas may report 1,000 units of product SKU 1234 while shipping records indicate only 950 units dispatched. This 50-unit difference signifies a discrepancy that must be investigated thoroughly. Detailed inventory audits are crucial, often involving cross-referencing physical counts with electronic inventory management systems. Furthermore, implementing robust tracking mechanisms such as RFID technology can mitigate similar issues in future operations. Regular reconciliation procedures can enhance overall efficiency and inventory accuracy.

Supporting Documentation

Shipping inventory reconciliation requires meticulous attention to detail and accurate documentation to ensure proper tracking and accountability. Essential records include packing slips (which detail items shipped) and bills of lading (which outline the shipment terms). Inventory counts taken at various intervals, such as quarterly or annually (for accurate assessment), help identify discrepancies. Additional supporting documentation may encompass delivery receipts (confirming shipment arrival) and electronic data interchange (EDI) reports (facilitating automated tracking). Maintaining these records in a centralized system enhances visibility and streamlines the reconciliation process. Accurate and timely reconciliation supports better inventory management, minimizes loss, and improves supply chain efficiency.

Requested Actions or Resolution

Shipping inventory reconciliation is a critical process for businesses, especially in logistics and supply chain management. Accurate tracking of items (often totaling thousands) ensures that discrepancies are identified promptly. Regular audits (conducted quarterly or biannually) help maintain inventory accuracy at different locations (like warehouses across the United States or Europe). Companies often rely on software solutions, such as Warehouse Management Systems (WMS), to streamline this process. Urgent resolution of mismatches can involve actions such as conducting cycle counts, reviewing shipping documentation, and verifying received goods against invoices. Maintaining effective communication with shipping carriers (like FedEx or UPS) is essential to resolve potential issues swiftly, ensuring an optimal flow of operations.

Closing and Response Deadline

Shipping inventory reconciliation involves an essential process of matching shipped items with inventory records to ensure accurate stock levels. Discrepancies may occur due to various factors, including miscounts during counting processes, damaged goods in transit, or improperly documented shipments, impacting overall inventory management efficiency. Companies like Amazon or Walmart emphasize strict reconciliation practices to maintain their robust supply chains, often setting a response deadline for reconciling discrepancies within five business days following inventory shipment. Close attention during this phase allows for the mitigation of potential financial losses and aids in maintaining customer satisfaction by ensuring product availability.

Comments