Are you preparing for a pre-shipment inspection and unsure how to draft the perfect appointment letter? This crucial step in the shipping process ensures that your goods meet quality standards before they leave the warehouse. With a well-crafted letter, you can communicate your needs clearly and set the stage for a smooth inspection. Let's explore some key elements to include in your letter to make it effectiveâread on for more insights!

Inspection Date and Time

Pre-shipment inspections play a crucial role in quality assurance, particularly for international trade. These inspections typically occur at supplier facilities or warehouses. Appointment scheduling generally requires clear communication about the inspection date and time, allowing ample preparation for both inspectors and suppliers. This process is essential for ensuring compliance with standards set by entities such as the International Organization for Standardization (ISO). Adhering to prescribed timelines helps avoid delays in shipping and delivery, especially for large shipments involving multiple products. Importantly, confirming appointment details in advance enhances the efficiency of the inspection and aligns expectations among all stakeholders involved in the transaction.

Inspection Location Details

Pre-shipment inspections are critical quality control processes that ensure products meet specified standards before they are shipped. Essential details for the inspection location include the factory address (typically including street name, city, and postal code), specific inspection area within the facility (such as production floor, quality assurance department), and contact information for the responsible personnel (including names, phone numbers, and email addresses). Additionally, the appointed date and time of the inspection should be clearly stated to avoid scheduling conflicts, along with any necessary access requirements (such as security badges or safety gear). Accurate logistics for transportation arrangements to the inspection site should also be confirmed in advance to facilitate smooth entry and allow ample time for thorough evaluations of the goods being checked.

Product Description and Quantity

A comprehensive pre-shipment inspection (PSI) evaluates the quality and conformity of products before shipment to ensure compliance with specified standards and customer expectations. Typically conducted by third-party inspection agencies, this process involves scrutinizing various aspects, including product specifications, manufacturing quality, and packaging requirements. For instance, a shipment of 5000 durable outdoor tents manufactured by a company in China may be assessed for stitching strength, waterproof materials, and proper labeling. Detailed documentation, including product descriptions and quantities, is essential for smooth inspection operations, as discrepancies can lead to delays or rejections at customs. Additionally, inspections usually occur at the supplier's facility, providing an opportunity to address any issues prior to export.

Contact Information for Coordination

Pre-shipment inspections ensure the quality and compliance of goods before they leave a manufacturing facility. Accurate contact information plays a crucial role in coordination between manufacturers, inspection agencies, and shipping companies. Key details include names, phone numbers, emails for communication. Address specifics like street names, city, and postal codes are essential for location identification. Companies involved in inspection may include Bureau Veritas, SGS, or Intertek, known globally for quality assurance services. Scheduling inspections in advance is vital to avoid delays in shipping timelines, impacting overall supply chain efficiency.

Specific Inspection Requirements or Checklist

Pre-shipment inspections play a crucial role in ensuring quality and compliance before goods are shipped. Specific inspection requirements may include verifying product specifications, conducting functional tests on electronic devices, and checking packaging integrity to meet international shipping standards. A detailed checklist could encompass aspects such as product dimensions, weight, manufacturer's quality certifications, and safety compliance certifications like CE or UL. For textiles, fabric quality, colorfastness, and stitching techniques might be evaluated. In the context of machinery, operational tests should assess performance under various conditions. Timeliness is vital; inspections should be scheduled at least two weeks before the shipping date to address any discrepancies promptly. Key inspection locations such as factories in China or Vietnam may dictate the need for certified inspectors proficient in the local regulatory environment.

Letter Template For Pre-Shipment Inspection Appointment Samples

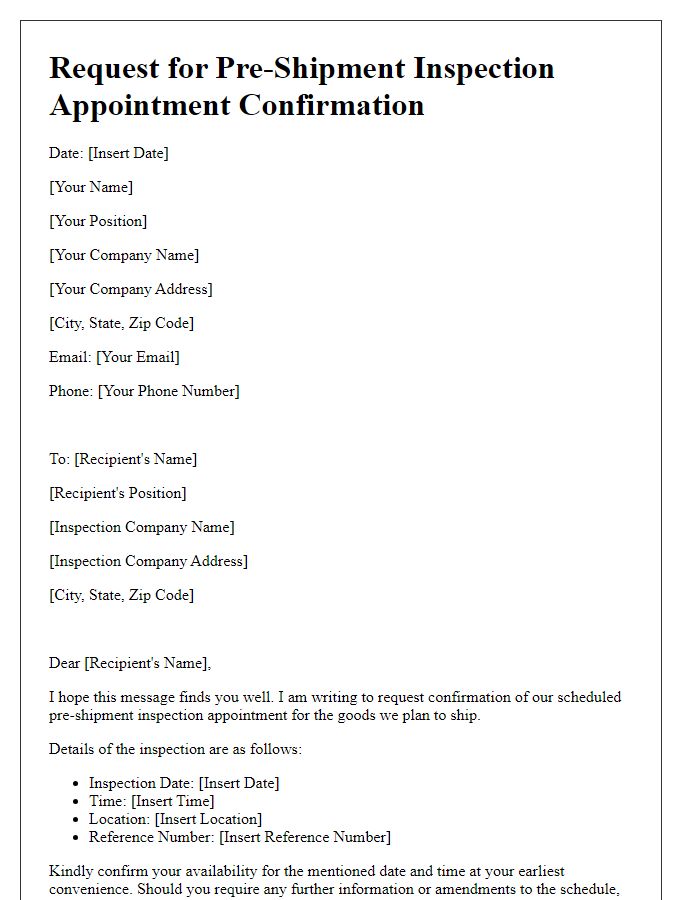

Letter template of request for pre-shipment inspection appointment confirmation

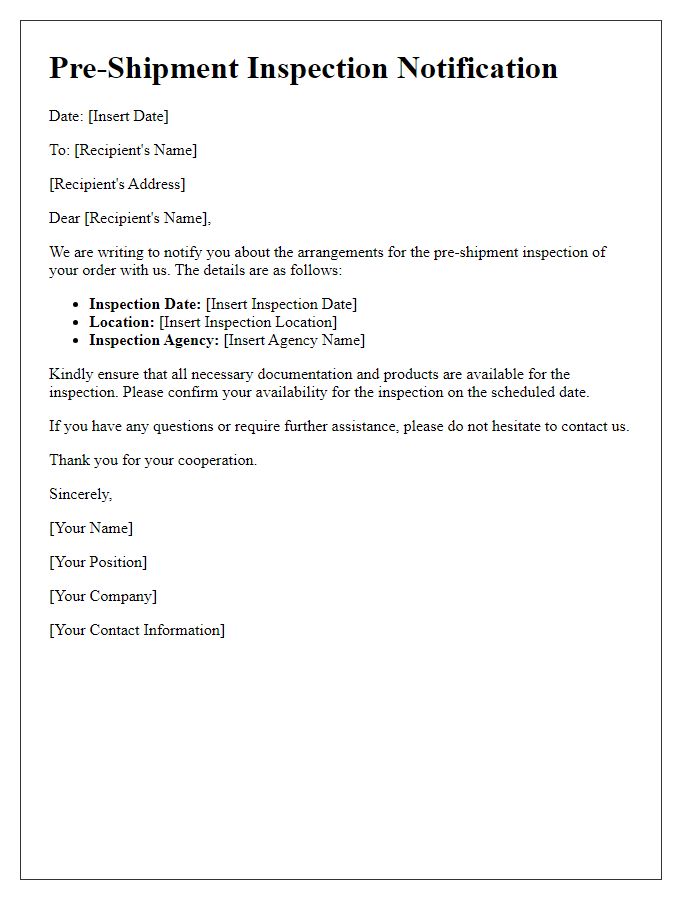

Letter template of notification for pre-shipment inspection arrangements

Comments