Are you looking to streamline your packaging process and ensure compliance with detailed requirements? Crafting the perfect letter can make all the difference in communicating your needs effectively. With the right template, you can outline specifications clearly and get all stakeholders on the same page. Dive into our comprehensive guide to discover how to create an impactful letter for your packaging requirements!

Clarity and Specificity

Detailed packaging requirements ensure clarity and specificity in the shipping process. Packaging materials such as corrugated boxes, bubble wrap, and biodegradable packing peanuts play crucial roles in protecting items during transport. Each box must meet specific dimensions (for instance, not exceeding 36 inches in length) and weight limits (generally capped at 70 pounds for most carriers). Labels should contain detailed information including sender name, recipient address, tracking number, and handling instructions like "fragile" or "this side up." Adhering to regulations set by shipping entities, such as the United States Postal Service (USPS) or FedEx, is essential to prevent delays. Proper packaging prevents damage to contents, optimizing safety and ensuring items arrive at destinations, such as retail stores or individual consumers, without incidents.

Material and Sustainability

Sustainable packaging plays a crucial role in minimizing environmental impact, especially in the consumer goods sector. Biodegradable materials, such as compostable bioplastics derived from plant sources, can significantly reduce landfill waste. Recyclable materials, including corrugated cardboard and glass, lower resource consumption when reused in new product manufacturing. The packaging design should prioritize minimalism, reducing excess material while ensuring product protection during shipping and handling. Certifications like FSC (Forest Stewardship Council) for paper products and a general commitment to reducing carbon footprint are pivotal in appealing to environmentally-conscious consumers. Additionally, adopting lightweight designs can decrease transportation emissions, threading sustainability through every facet of the packaging lifecycle.

Compliance and Regulations

Packaging requirements play a crucial role in product safety and regulatory compliance, especially in industries such as food and pharmaceuticals. Each region, such as the European Union or the United States, has specific regulations like the Food Safety Modernization Act (FSMA) or Regulation (EC) No 1935/2004 that govern packaging materials, ensuring they do not contaminate products. Mandatory labeling must include details such as batch numbers, expiration dates, and allergen information to meet consumer safety standards. Furthermore, eco-friendly packaging solutions, like biodegradable materials derived from cornstarch, are gaining traction, driven by consumer demand for sustainability. Strict adherence to these regulations is essential, as non-compliance can lead to hefty fines or product recalls that can significantly impact brand reputation and financial stability.

Labeling and Branding

Labels play a crucial role in product identification and consumer appeal, especially in retail environments. Clear labeling elements such as product name, weight (measured in grams or pounds), ingredients list, and nutritional information contribute to regulatory compliance and customer awareness. Branding elements include logos and color schemes, which should align with the company's overall brand identity for consistency. Additionally, the placement of labels is important; mandatory information should be prominently displayed on the front, while additional details can be allocated to the back or sides. Barcodes are another vital component, facilitating inventory management and sales tracking. Furthermore, packaging materials should consider sustainability practices, using recyclable or biodegradable options to enhance eco-friendliness and appeal to environmentally conscious consumers.

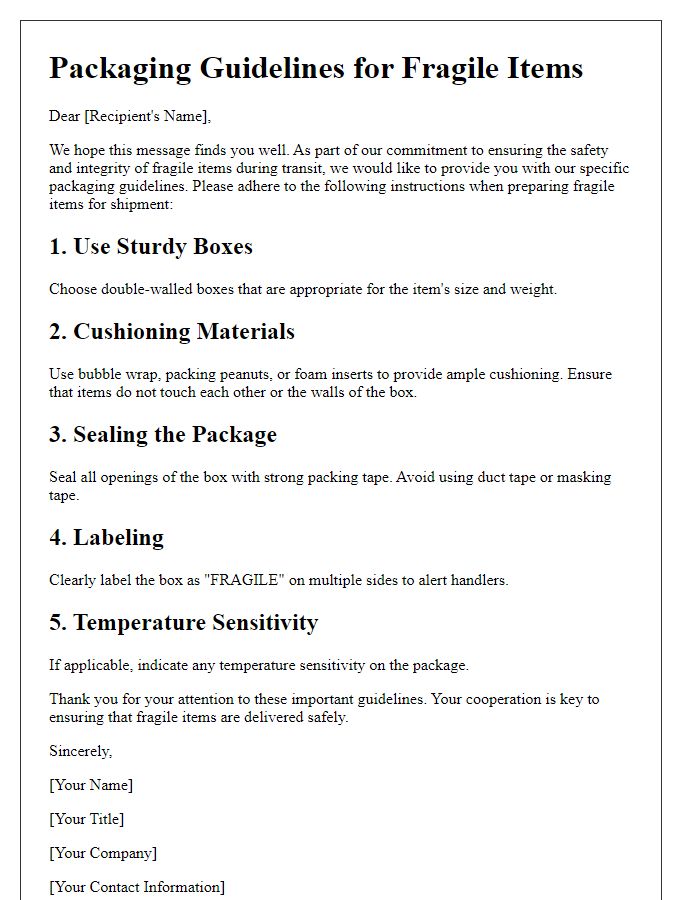

Protection and Safety

Effective packaging requirements ensure protection and safety for various products during shipping and handling. Adequate cushioning materials such as bubble wrap (typically 0.5 to 1 inch thickness) should surround delicate items to prevent damage from vibrations or impacts. Sturdy outer boxes, preferably made from double-wall corrugated cardboard, provide essential structural integrity, capable of withstanding a minimum of 32 ECT (Edge Crush Test) for robust support. Utilizing moisture-resistant materials is crucial in environments with high humidity, preventing deterioration of products, particularly for electronics and perishables. Employing tamper-evident seals and labeling ensures the security of the contents and informs recipients about handling requirements, significantly reducing safety risks during transit.

Letter Template For Detailed Packaging Requirements Samples

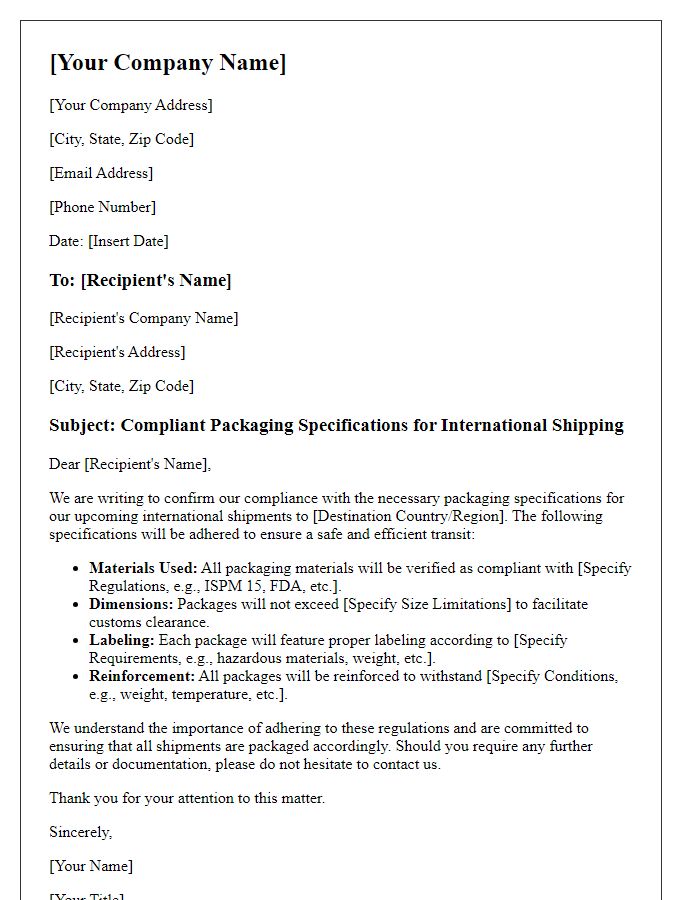

Letter template of compliant packaging specifications for international shipping

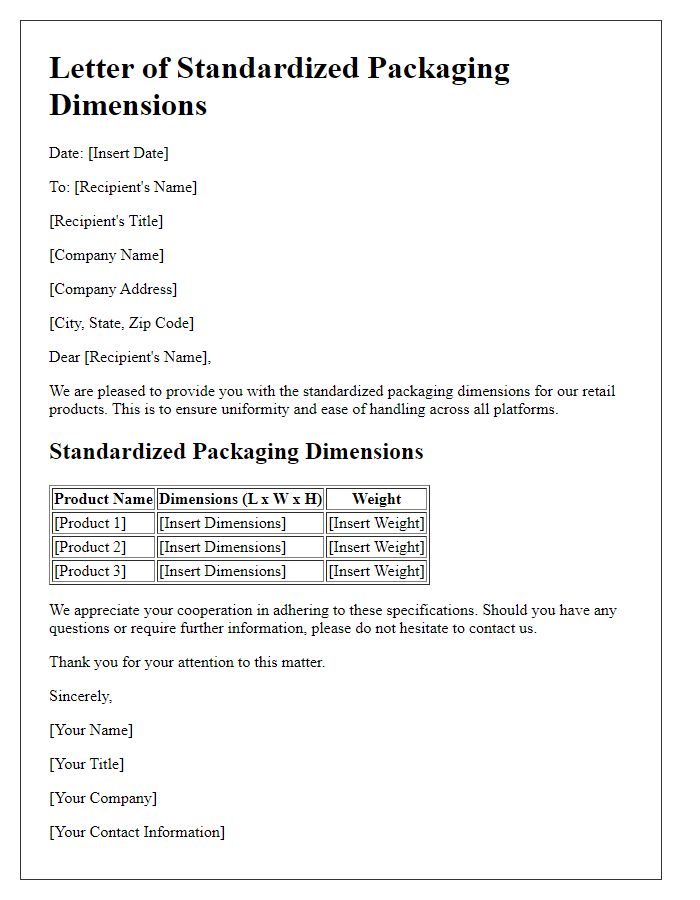

Letter template of standardized packaging dimensions for retail products

Comments