As the holiday season approaches, it's time to start planning your production schedule to ensure a smooth and festive experience. Whether you're ramping up for a surge in orders or coordinating events, organizing your workflow can make all the difference. This is the perfect opportunity to reflect on past successes and find ways to enhance your efficiency. Join us as we delve into best practices and tips for creating an effective holiday production schedule that will set you up for success!

Tone and Style

Holiday production schedules outline critical timelines for manufacturing and distributing goods during peak shopping seasons, such as Thanksgiving, Christmas, and New Year's. These schedules often span several months, beginning in September and extending through January, emphasizing high-demand products like toys, electronics, and holiday decor. Key dates include order deadlines, shipping cutoffs, and inventory restock dates, ensuring timely fulfillment and customer satisfaction. Coordination among departments--such as marketing, logistics, and sales--is essential for maximizing efficiency and reducing delays. Seasonal factors like weather conditions and shipping availability also impact production schedules, requiring adaptability and contingency planning to meet consumer demand effectively.

Schedule and Deadlines

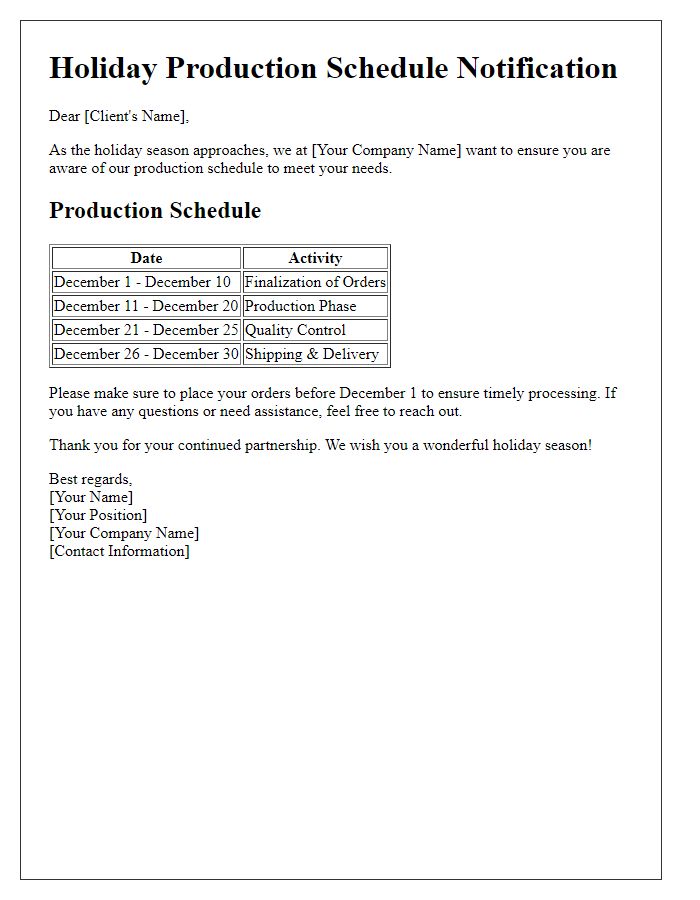

The holiday production schedule for 2023 emphasizes crucial deadlines and milestones for timely completion. Starting on November 1, the pre-production phase will involve finalizing designs and gathering necessary materials, with a deadline of November 15. Manufacturing processes will commence on November 20, aiming for a completion date of December 10 to ensure adequate time for quality checks. Packaging and labeling will begin on December 11, with an expected wrap-up by December 18, preparing products for distribution. Shipping preparations will take place from December 19 to December 22, allowing products to reach retailers and consumers before Christmas Day. Additionally, a comprehensive review will occur on December 23 to assess production efficiency and address any outstanding issues.

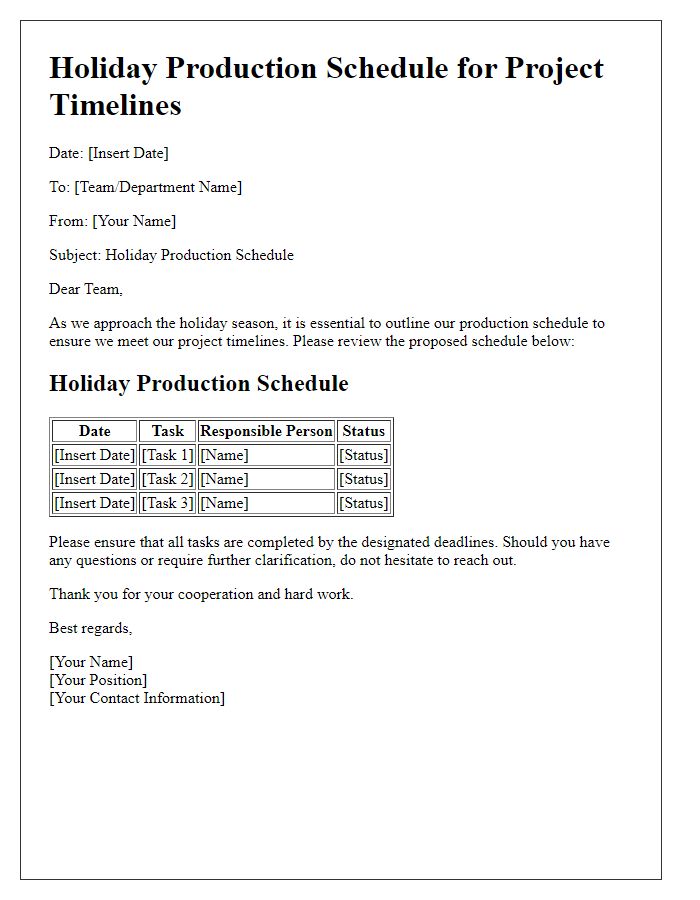

Roles and Responsibilities

The holiday production schedule outlines essential roles and responsibilities for ensuring efficient operation during the peak season. Production Managers oversee daily tasks, coordinate teams, and monitor workflow efficiency, focusing on optimizing output to meet increased demand. Quality Control Inspectors are responsible for maintaining product standards, conducting inspections, and implementing corrective measures if defects arise. Warehouse Staff manage inventory, facilitating timely deliveries and organizing supplies based on predefined protocols. Human Resources coordinate schedules, ensuring adequate staffing levels and addressing employee inquiries. Logistics Coordinators handle shipment plans, optimizing routes for cost-effective distribution, and monitoring transit times to maintain customer satisfaction. Each role is crucial in fostering a collaborative environment, ensuring smooth production, and achieving organizational goals during the high-demand holiday period.

Contact Information

The holiday production schedule for the upcoming 2023 season requires accurate contact information for effective communication among team members. Key stakeholders include the production manager in New York City, who oversees logistics and timelines, and the marketing director based out of Los Angeles, responsible for promotional strategies. Additionally, the warehouse supervisor in Chicago coordinates inventory management and shipping, ensuring timely distribution to retail partners. Each of these roles is critical for maintaining efficiency throughout the busy holiday period, with deadlines extending from late October through December 2023 to accommodate peak demand. Ensuring clarity in contact details can facilitate quick resolution of any production or distribution issues.

Key Reminders and Guidelines

The holiday production schedule plays a crucial role in ensuring a smooth workflow during peak seasons like Christmas and Thanksgiving. Essential to note, production timelines must align with key dates such as December 25 for Christmas, ensuring item availability for retailers and consumers alike. Each department, including logistics and marketing, has specific deadlines; for instance, marketing campaigns ideally launch by early November to maximize outreach. Resource allocation is vital, particularly with supply chains that may experience disruptions during the holiday season. Focus on production capacity, expected demand trends, and workforce scheduling to optimize operations. Maintain open communication among teams to adjust plans based on real-time performance metrics or unforeseen events, like supply shortages or labor availability issues.

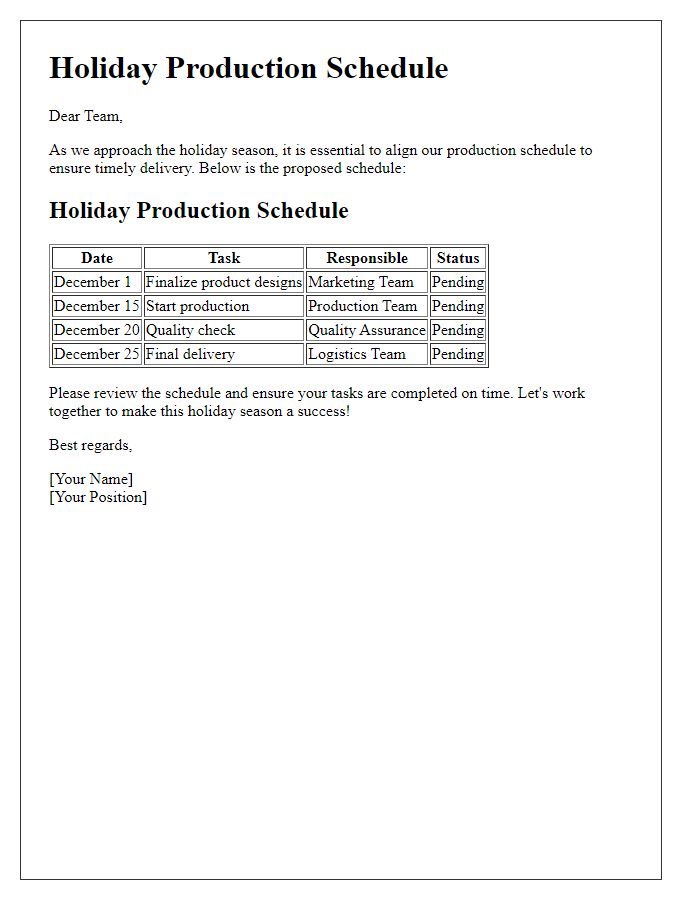

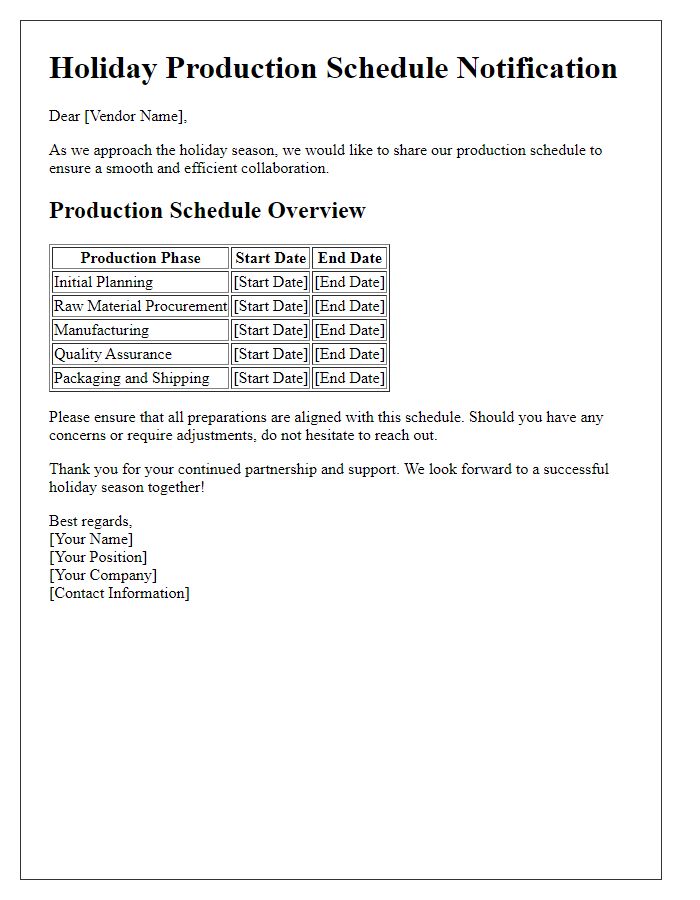

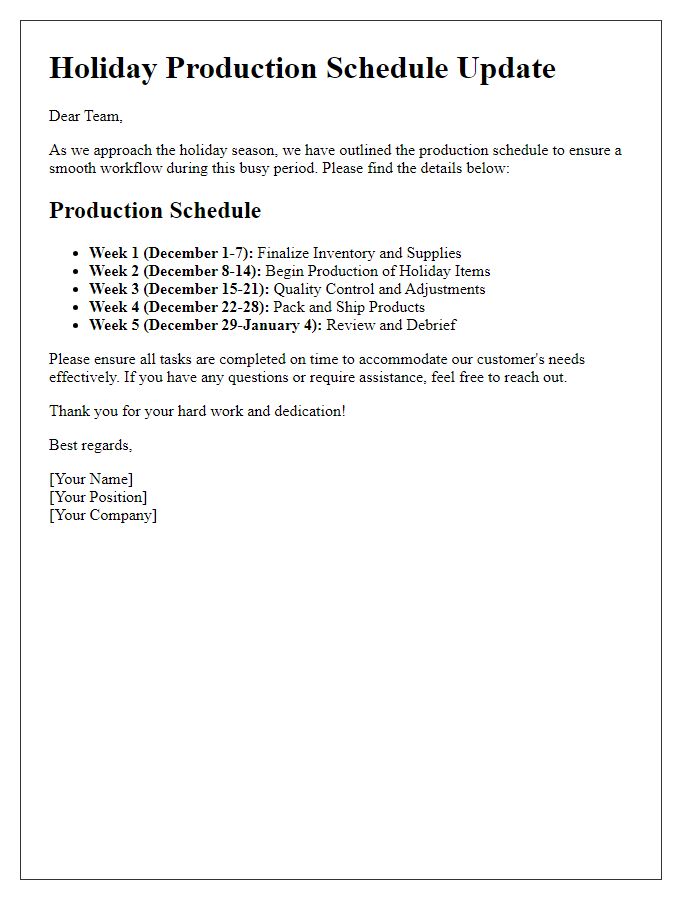

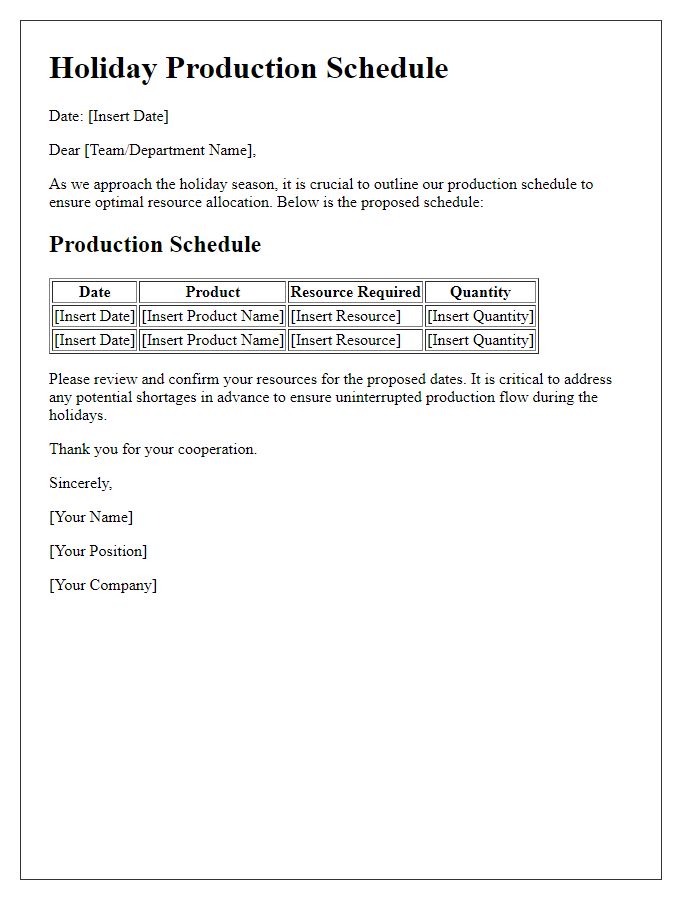

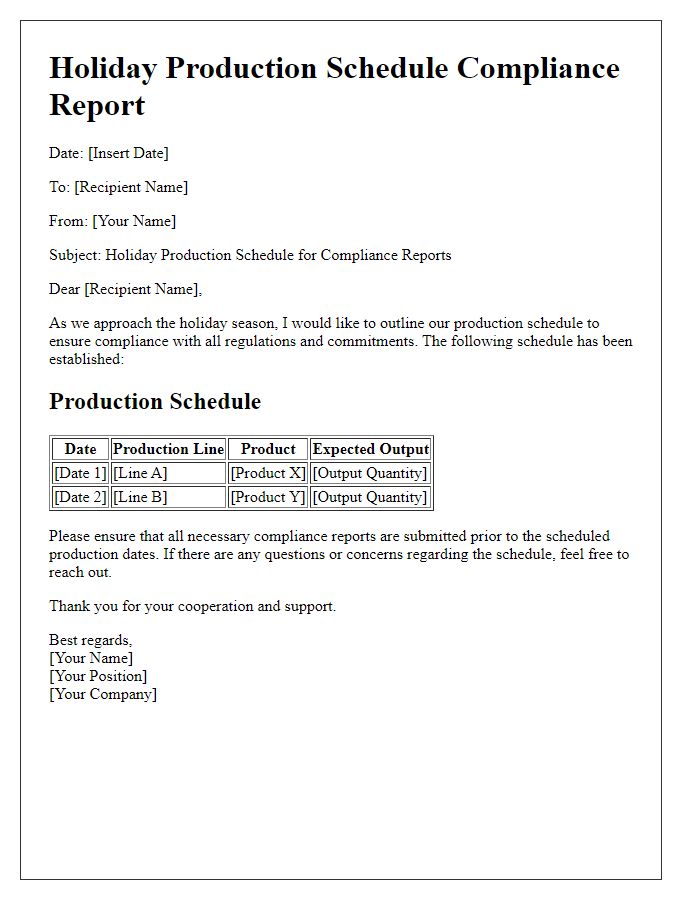

Letter Template For Holiday Production Schedule Samples

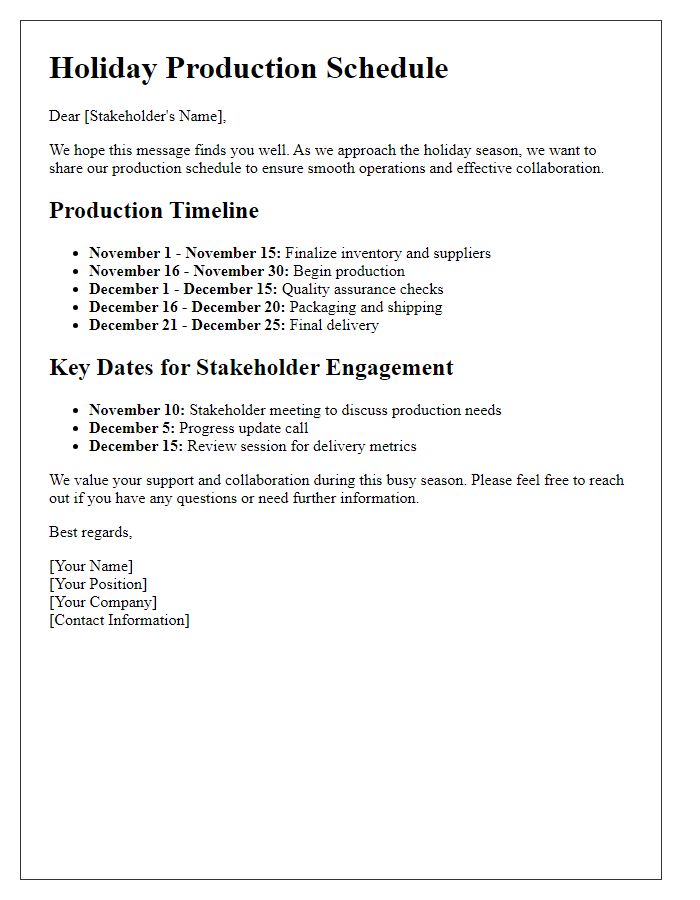

Letter template of holiday production schedule for stakeholder engagement

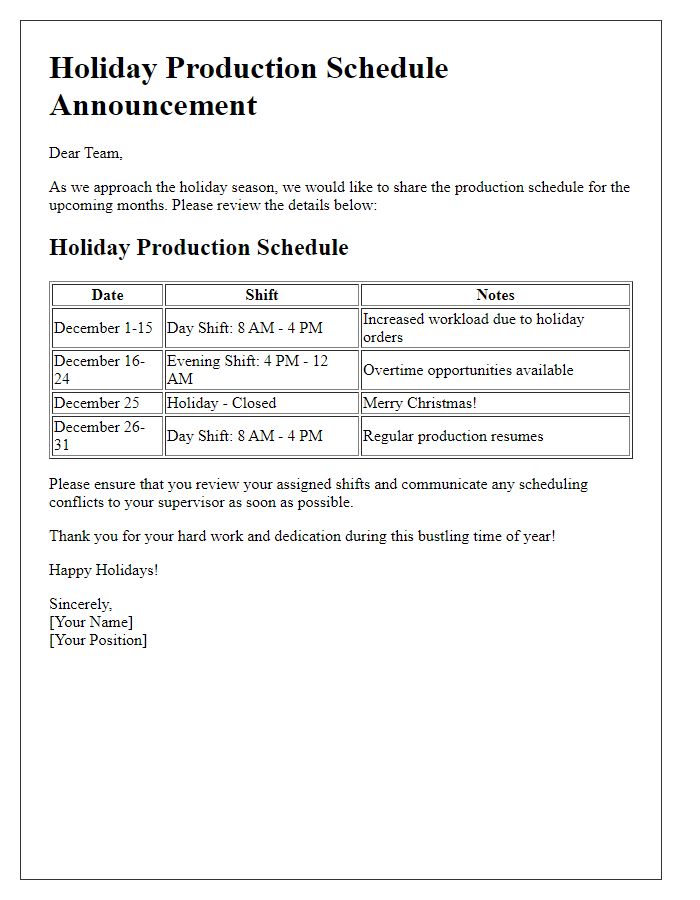

Letter template of holiday production schedule for employee announcements

Comments