Hey there! If you've ever wondered how businesses manage to handle returns and exchanges seamlessly, you're in the right place. Reverse logistics is the fascinating process that enables companies to recover value from products that are no longer in use, whether due to returns, repairs, or recycling. Join me as we explore the key elements and best practices of reverse logistics that can enhance efficiency and boost customer satisfactionâlet's dive in!

Return Authorization Number (RAN)

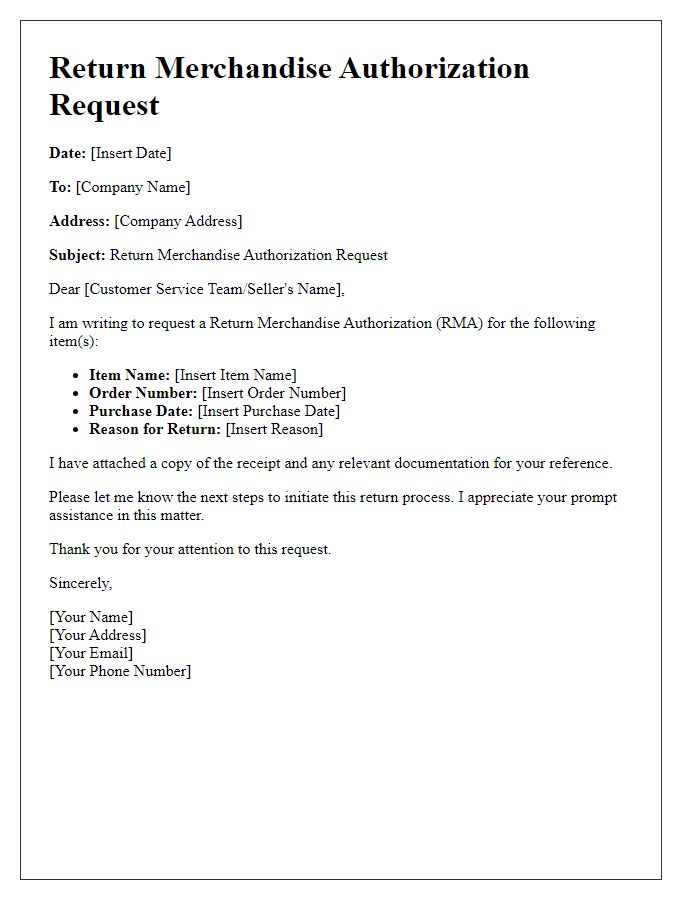

Reverse logistics involves the management of products returning from consumers back to the manufacturer or distribution center. The Return Authorization Number (RAN) acts as a crucial identifier for tracking returned merchandise within the logistics supply chain. For instance, items such as electronics, apparel, or furniture must be processed through defined channels to ensure returns are executed smoothly, adhering to company policies established by brands such as Amazon or Walmart. Regardless of the nature of the product, each return should include a unique RAN, allowing teams to monitor inventory levels and manage restocking effectively. Additionally, this number facilitates streamlined communication between customers and customer service representatives, helping to resolve issues promptly and maintain customer satisfaction during the return process.

Reason for Return

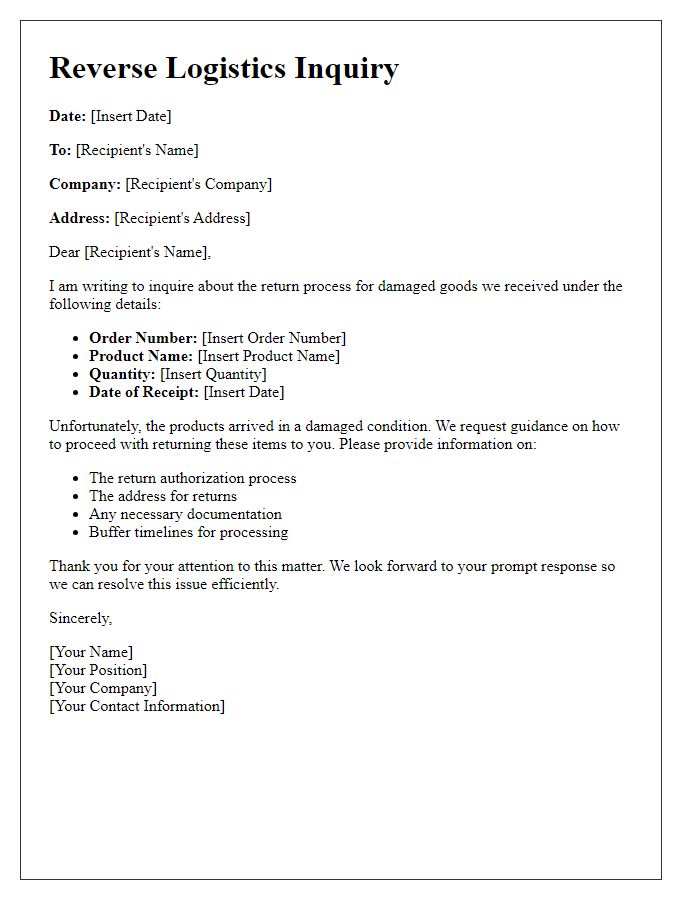

The reverse logistics process for handling the reason for return involves systematic assessment and action beginning with the identification of the specific issue prompting the return, such as defective merchandise or customer dissatisfaction. In 2022, a survey conducted by returns management specialists indicated that approximately 30% of returns stemmed from sizing issues, highlighting the importance of accurate product descriptions and size charts for e-commerce retailers. Retail locations, such as Target and Amazon, have developed streamlined return policies allowing customers to initiate a return through mobile applications, enhancing customer experience and retention. Furthermore, efficient reverse logistics strategies can reduce overall costs by minimizing unnecessary transportation and improving inventory turnover rates. Effective communication of return reasons to the supply chain can inform improvements in product quality and design, ultimately reducing future returns and increasing customer satisfaction.

Product Condition and Packaging Instructions

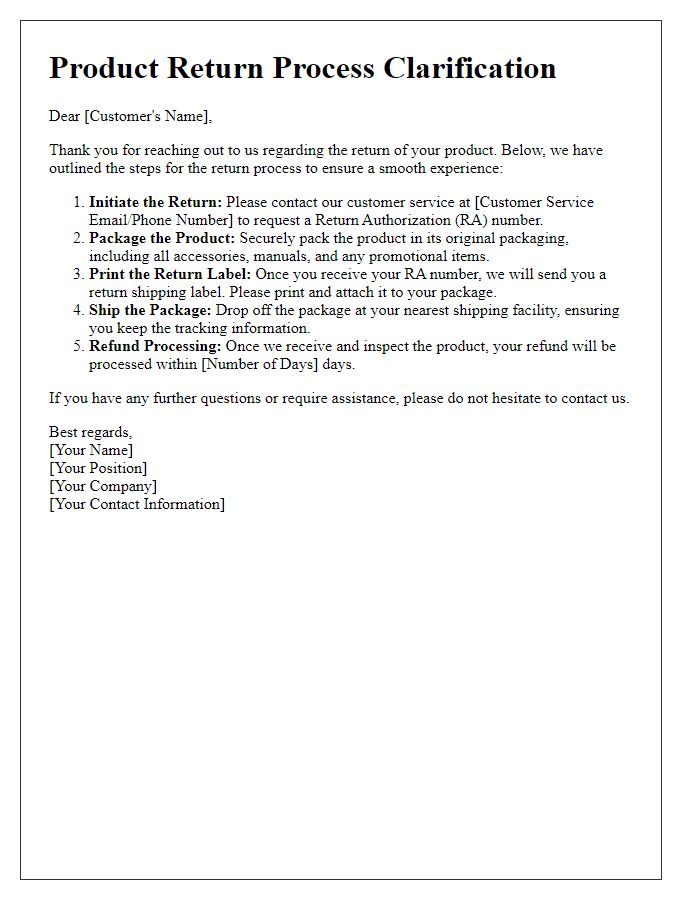

In reverse logistics, product condition and packaging instructions play a crucial role in ensuring efficient returns and refurbishments. Products, such as electronics, must be assessed for functionality and cosmetic condition before returning (e.g., "like new," "open box," "damaged"). Packaging guidelines often include original packaging requirements (preferably intact) and cushioning materials (such as bubble wrap) to protect items during transit (preferably via a reliable carrier like FedEx or UPS). Labels should include return tracking numbers to streamline processing at return centers, such as those located in major distribution hubs (e.g., Memphis or Louisville). Proper adherence to these instructions minimizes losses and maximizes recovery value for companies engaged in reverse logistics operations.

Return Shipping Address and Procedures

The reverse logistics process involves essential steps for managing product returns effectively. Clear return shipping addresses facilitate streamlined returns for customers, ensuring items are sent back to designated facilities, such as Amazon Fulfillment Centers or Manufacturer Warehouses. Detailed procedures include requesting a Return Merchandise Authorization (RMA) number, typically issued within two business days, and requirements for packaging, like using original boxes or a sturdy alternative to prevent damage during transit. Additionally, customers must be notified of shipping label issuance, which often expires within 14 days, providing expiration alerts. Policies may vary by company, making it crucial to consult specific guidelines for authorization and refund timelines, often ranging from 7 to 21 days after receipt at the return location.

Contact Information for Queries

The reverse logistics process involves the management of returned goods, emphasizing efficiency and sustainability in supply chain operations. For any inquiries regarding returns, customers can reach out to designated contact points, which typically include customer service hotlines or dedicated email addresses. In many organizations, a specific Returns Department, staffed with trained specialists, ensures prompt resolution of return-related issues. The contact information often includes hours of operation, ensuring that customers can receive assistance during designated periods, typically Monday to Friday, 9 AM to 5 PM. For example, companies may provide a toll-free number such as 1-800-555-0199 and an email address like returns@company.com to facilitate communication and resolve issues effectively.

Comments