In today's fast-paced global market, proactive shipment management is essential for businesses looking to stay ahead of the competition. By anticipating potential delays and streamlining logistics, companies can enhance customer satisfaction while reducing costs. This approach not only simplifies operations but also fosters stronger relationships with suppliers and partners. Want to discover more about effective strategies for proactive shipment management? Read on!

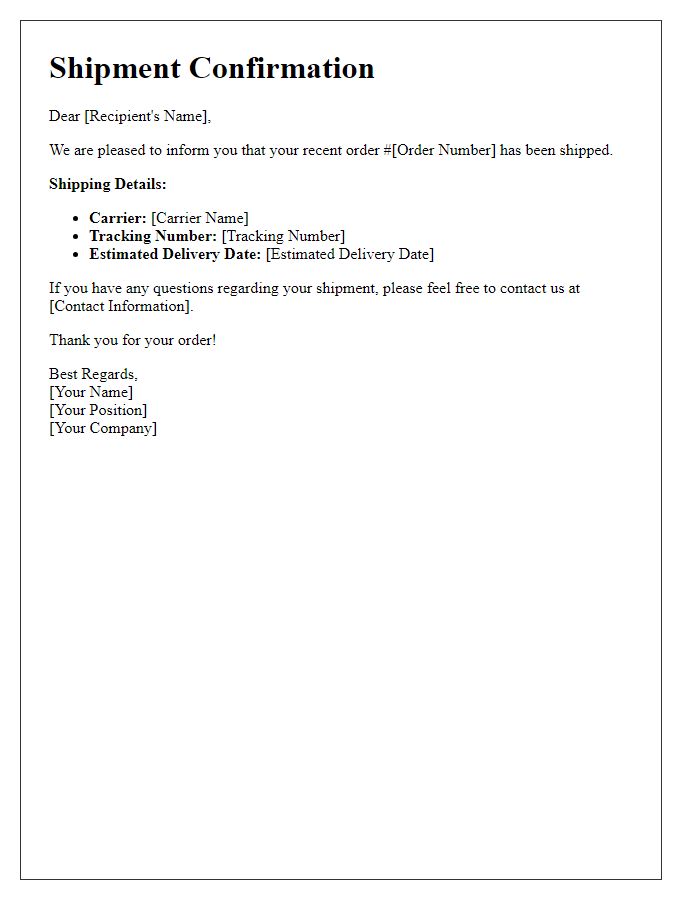

Clear subject line

Proactive shipment management enhances logistical efficiency for companies. Timely communication about shipment statuses can mitigate delays, improving customer satisfaction. Accurate tracking of packages through designated carriers such as FedEx or UPS ensures up-to-date information. Utilizing advanced software platforms (like ShipStation) allows for streamlined monitoring and alerts regarding unusual shipping patterns. Regularly scheduled check-ins with suppliers at key ports, such as Los Angeles or New York, can help identify potential bottlenecks in the supply chain. Effective documentation, including customs forms and freight invoices, guarantees compliance with international shipping regulations, reducing the risk of costly fines. Prioritizing proactive measures significantly contributes to maintaining a smooth operational flow.

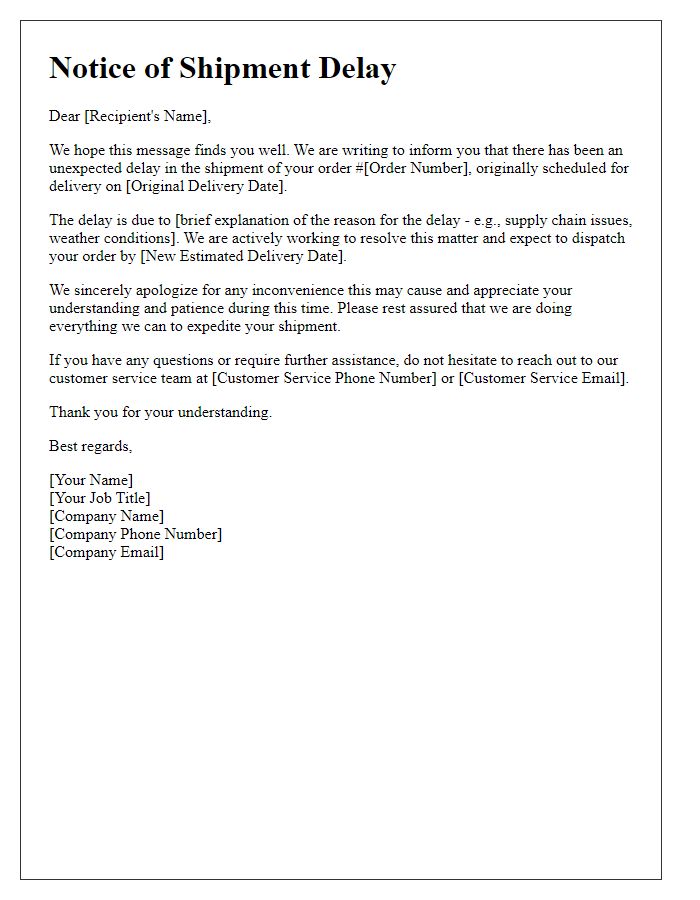

Detailed shipment information

Proactive shipment management relies on comprehensive shipment information to ensure efficiency and transparency in logistics operations. Shipments typically consist of essential details such as tracking numbers, originating locations, and destination addresses for packages, often indicating critical points like major cities or international borders. Scheduled departure and arrival times play a crucial role, particularly for time-sensitive deliveries that require adherence to deadlines. Additionally, shipment weight and dimensions are vital for calculating shipping costs and compliance with carrier restrictions. Shipment status updates--ranging from departure, transit, to delivery confirmation--provide real-time tracking for shippers and recipients, facilitating proactive adjustments to unforeseen delays. Finally, integrating customs documentation for international shipments is paramount, as it ensures compliance with trade regulations and minimizes the risk of customs-related delays.

Contact information for inquiries

Proactive shipment management relies on clear communication and accessibility. Effective contact information should include phone numbers, such as a direct line (1-800-555-0199) and fax (1-800-555-0198) for immediate inquiries. Email addresses, like support@shippingcompany.com, should be readily available for detailed questions. A dedicated customer service webpage may provide real-time tracking tools and live chat options. Physical addresses, such as the corporate office located in Seattle, Washington, can add a level of trust and professionalism. Clear instructions on business hours (Monday to Friday, 9 AM to 5 PM PST) facilitate timely responses and effective issue resolution.

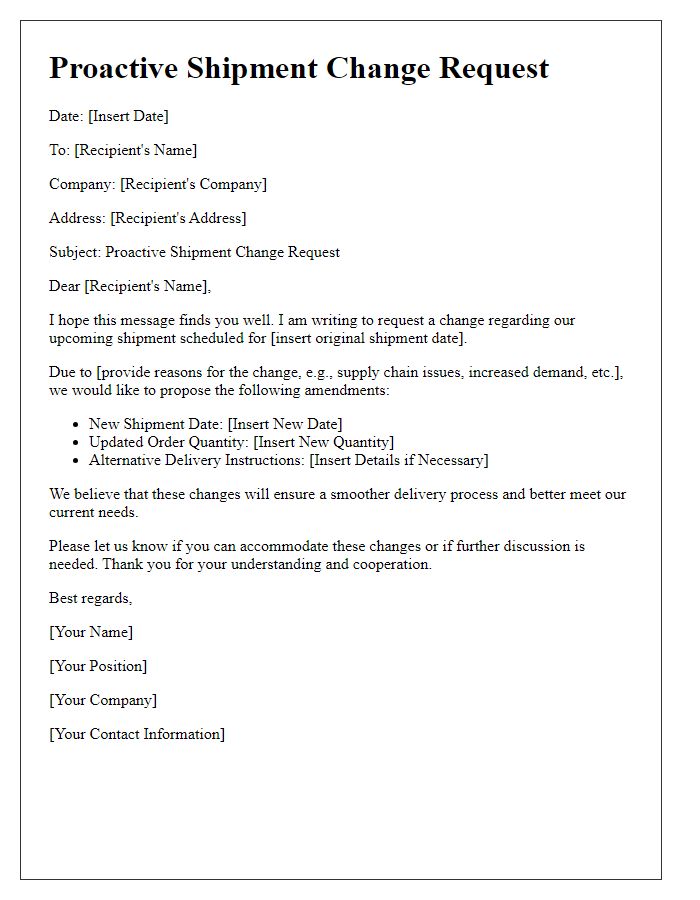

Proactive issue resolution steps

Proactive shipment management involves implementing proactive issue resolution steps to enhance logistical efficiency. First, advanced tracking systems such as GPS-enabled devices allow real-time monitoring of delivery trucks across major shipping routes, including Interstate 5 in California. Secondly, predictive analytics tools analyze historical shipment data, identifying patterns that may lead to delays, such as peak seasons or adverse weather events like hurricanes, influencing ports like New Orleans. Thirdly, contingency plans, which may include alternative suppliers or routes, ensure minimal disruption during unexpected occurrences, safeguarding delivery timelines. Furthermore, regular communication with shipping partners and freight carriers, like FedEx or UPS, provides crucial updates, facilitating swift adjustments in response to new challenges. By maintaining an agile shipment strategy, companies can effectively mitigate issues before they escalate, ensuring consistent service quality.

Personalized closing statement

Proactive shipment management involves carefully monitoring logistics processes to ensure timely deliveries. Key components include tracking packages using sophisticated software, analyzing transit times for potential delays, and employing strategies for optimization to reduce inefficiencies. In the United States, the shipping industry has seen exponential growth, with more than 13 billion packages delivered in 2021 alone, highlighting the importance of effective management. Companies like UPS and FedEx utilize advanced algorithms to predict delivery windows, ensuring customers receive accurate updates. Optimizing routes can reduce fuel costs significantly, directly impacting operational efficiency and customer satisfaction. Overall, proactive shipment management not only streamlines operations but enhances the overall customer experience.

Comments