Hey there! If you're managing a business, you know how crucial it is to keep track of your inventory. Unexpected shortages can disrupt operations and lead to unhappy customers. In this article, we'll guide you through writing an effective inventory shortage alert letter that communicates the issue professionally and clearly. So, grab a cup of coffee and let's dive into the details!

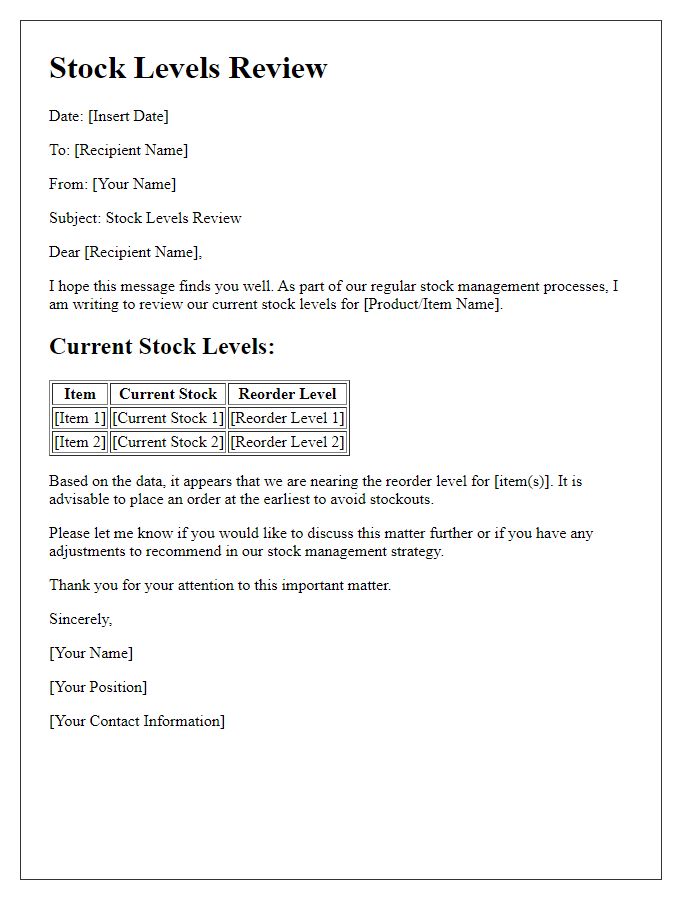

Subject Line

Inventory shortages can significantly impact business operations, especially in high-demand products such as electronics or seasonal items like holiday decorations. Low stock levels, typically defined as less than 20% of the usual inventory, can lead to missed sales opportunities and customer dissatisfaction. Quick response times are crucial for replenishment orders to suppliers, such as major distributors like Amazon or Alibaba, which can take anywhere from 3 to 14 days for delivery. Keeping an eye on inventory turnover rates can help predict shortages and optimize stock levels, ultimately safeguarding against potential revenue loss during crucial sales periods.

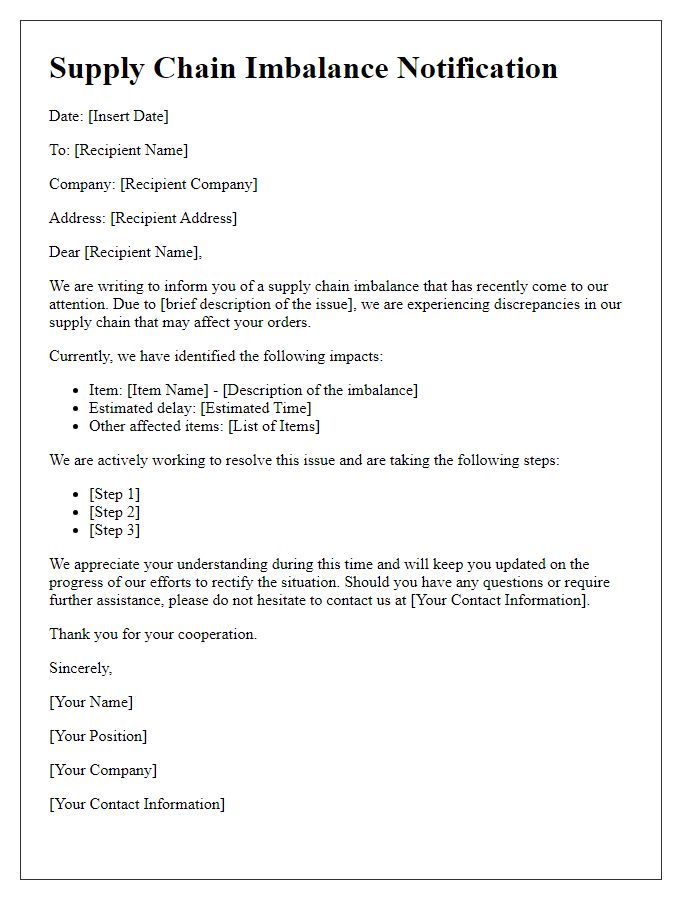

Recipient Identification

Inventory shortages can disrupt operations in retail sectors, particularly during peak sale periods such as Black Friday or holiday seasons. Insufficient stock of in-demand items like electronics, apparel, or groceries can lead to lost sales, decreased customer satisfaction, and potential harm to brand reputation. Proper identification of recipients, such as warehouse managers and supply chain coordinators, is crucial for timely communication regarding inventory levels. Accurate data on current stock counts, expected delivery dates from suppliers, and historical sales trends should be included. Implementing a systematic approach to alerting relevant personnel can mitigate impacts and initiate prompt actions to replenish essential items.

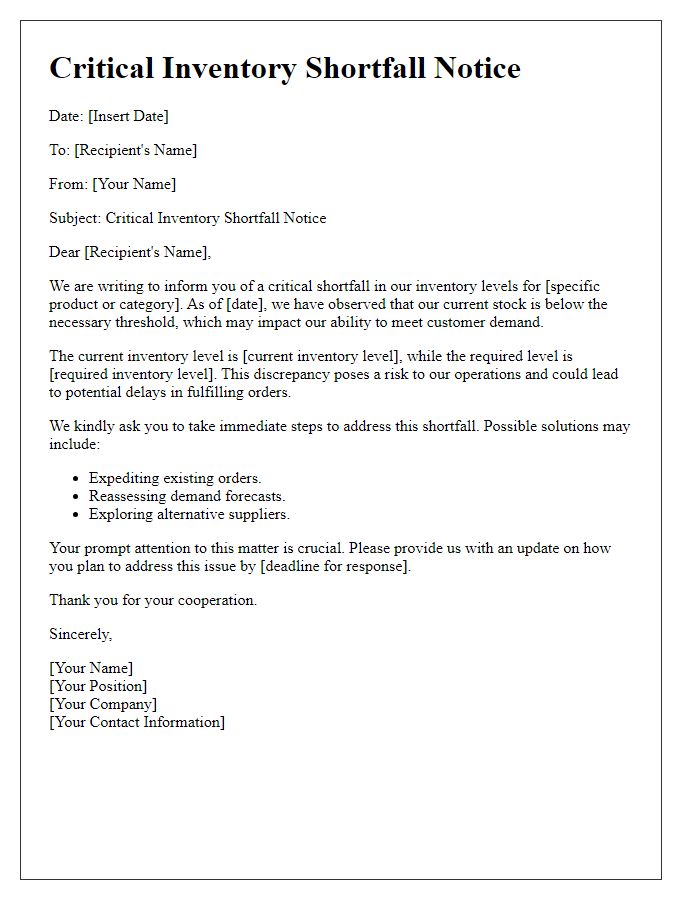

Description of Shortage

Inventory shortages can significantly impact business operations, particularly in retail or manufacturing sectors. A crucial example includes the recent depletion of 500 units of Product X, a popular electronic device, at our central distribution center located in Chicago, Illinois. Demand spikes, driven by a promotional event held between September 15 and September 20, 2023, exceeded forecasts, causing an unexpected sales volume. The shortage could disrupt supply chain continuity, affecting customer satisfaction and potentially leading to a loss of revenue estimated at $50,000 within the next quarter if not addressed. Prompt investigation into supplier capabilities and alternative sourcing options must be prioritized to rectify this inventory deficit.

Impact Assessment

An inventory shortage alert significantly impacts operational efficiency and customer satisfaction within retail environments. Insufficient stock levels of essential items, such as electronics or groceries, can lead to sales losses, estimated at around $1.1 trillion annually across the global retail sector. Affected locations, like major supermarkets and electronics chains, frequently struggle to meet customer demand, leading to increased frustration among shoppers. Additionally, the disruption in supply chains often results from factors such as global shipping delays due to geopolitical tensions or natural disasters. This situation may also increase overhead costs, as businesses invest more in expedited shipping methods or restocking efforts, further diminishing profit margins. Consequently, businesses must implement inventory tracking solutions and adopt proactive measures for effective demand forecasting.

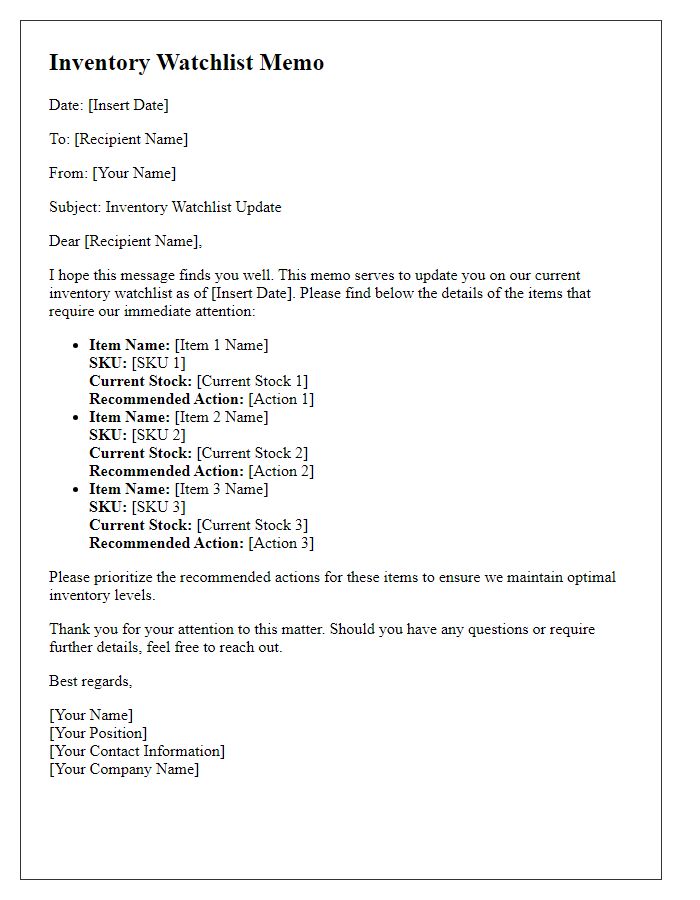

Call to Action

Inventory shortages can disrupt business operations and lead to lost sales opportunities. Monitoring stock levels is crucial for maintaining a steady supply chain, especially in retail environments like supermarkets. For example, when snack food inventory falls below the minimum threshold of 100 units, immediate replenishment becomes necessary to avoid customer dissatisfaction. Tracking metrics such as turnover rates and lead times will help in anticipating future shortages. Implementing real-time inventory management systems can improve visibility and ensure timely restocking, enabling businesses to meet customer demands effectively and sustain revenue.

Comments