Hey there! Keeping your boiler in tip-top shape is essential for a warm and cozy home, especially as we transition into the colder months. Regular maintenance not only ensures efficiency but also saves you from unexpected breakdowns and costly repairs down the line. In this article, we'll share some key updates on boiler maintenance procedures and tips to keep your system running smoothly. So, grab a cup of tea and read on for everything you need to know!

Greeting and Recipient's Name

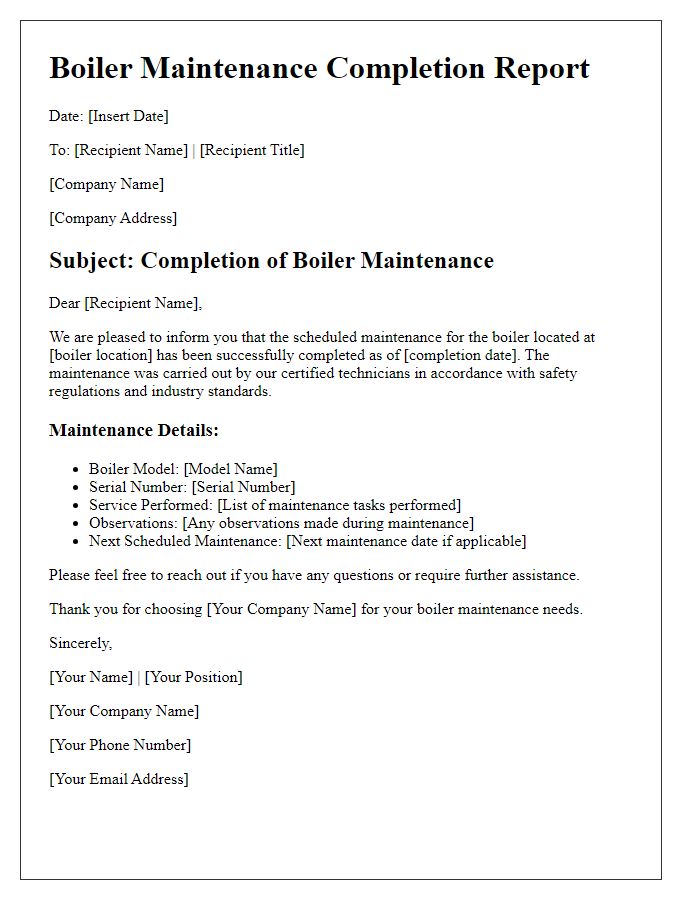

Regular boiler maintenance is crucial for the efficient operation of heating systems in residential and commercial buildings across regions. Annual inspections, typically performed during fall, ensure that components such as the heat exchanger and safety valves function properly, contributing to energy efficiency and safety. Neglected boilers can lead to higher energy bills - in some cases, up to 20% more due to inefficiencies - or even dangerous situations like carbon monoxide leaks. Scheduling maintenance with certified technicians keeps the system running optimally, prolonging the boiler's lifespan, which can exceed 15 years with proper care. Routine checks can also comply with local regulations, avoiding costly fines associated with non-compliance in regions like California and New York.

Purpose of the Letter

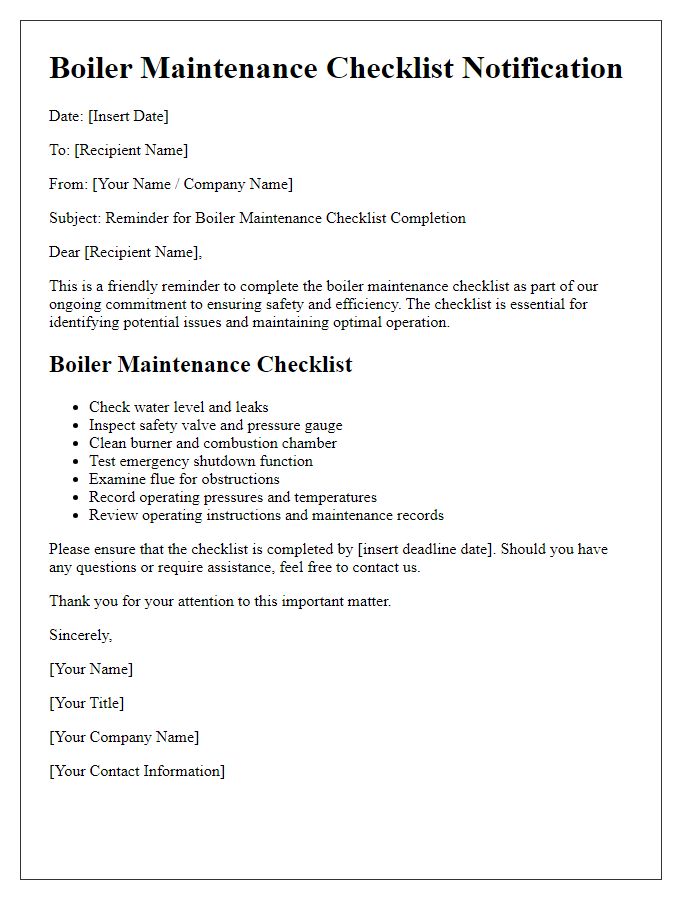

Boiler maintenance updates are crucial for ensuring optimal performance and safety of heating systems, such as gas or oil boilers. Regular inspections (ideally every 12 months) help identify issues such as leaks, corrosion, or inefficient combustion processes. These updates can enhance energy efficiency, lowering heating bills by up to 15% in homes located in colder regions, like the northeastern United States. Moreover, well-maintained boilers contribute to reducing the risk of hazardous situations, including carbon monoxide leaks, which cause serious health risks. Documentation of maintenance schedules and findings is essential for compliance with regulations set forth by organizations like the Occupational Safety and Health Administration (OSHA).

Specific Maintenance Details

Routine boiler maintenance ensures optimal performance and longevity of heating systems, including gas and oil-fired boilers, typically found in residential and commercial buildings. Regular checks, ideally carried out annually (often recommended during the fall, before winter usage), involve inspecting critical components such as the heat exchanger, ignition system, and safety controls. Technicians often perform tasks like cleaning burners and checking flue pipes to ensure proper ventilation, with a focus on efficiency ratings which can significantly impact energy bills. Failure to maintain boilers can lead to issues such as increased fuel consumption, reduced heating efficiency, and potential safety hazards related to carbon monoxide leaks, particularly in older models manufactured before 2010.

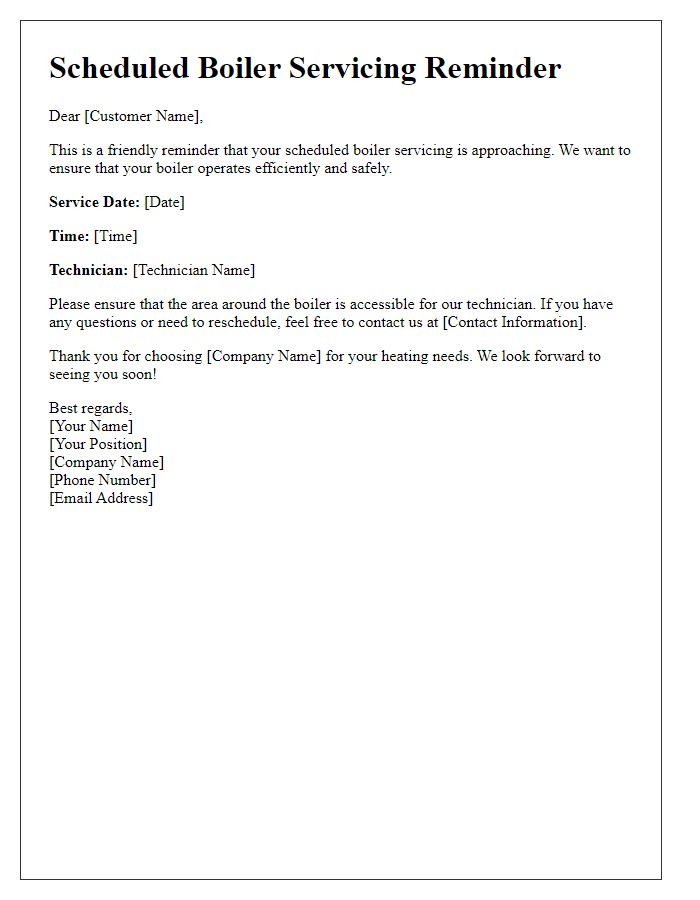

Schedule and Timeline

Regular boiler maintenance is crucial for ensuring optimal performance and safety in residential and commercial settings. Scheduled maintenance, typically occurring annually or biannually, involves a comprehensive inspection of key components, including the heat exchanger, burner, and safety controls. During this process, technical experts will clean and check for any signs of wear or inefficiency, helping to prevent potential failures and costly repairs. For businesses operating in colder climates, such as the Northeast U.S., maintenance before winter months (typically October-November) is especially vital to ensure reliability during peak usage. A detailed timeline outlining the scheduling of services, anticipated downtime, and completion dates ensures minimal disruption to daily operations while maintaining a warm, comfortable environment.

Contact Information and Support

With the changing seasons, regular boiler maintenance is essential for efficient heating in residential buildings, such as those in the UK. Scheduled inspections typically occur every year, ideally in autumn before colder months set in. Boiler types, such as combi boilers or system boilers, may vary in service needs. Essential support services, including a gas safe registered engineer, ensure compliance with safety regulations. Contact information for these professionals should include not only a phone number but also an email address for urgent inquiries or appointment bookings. Documenting maintenance history can enhance efficiency and support warranty claims, providing peace of mind for homeowners.

Comments