Are you wondering how to effectively check on the availability of your suppliers? Reaching out with a well-crafted inquiry can make all the difference in ensuring a smooth supply chain. In this guide, we'll explore the essential components of a supplier availability inquiry letter, designed to obtain the information you need quickly and efficiently. So, let's dive into the details and discover the best practices for crafting your own inquiry!

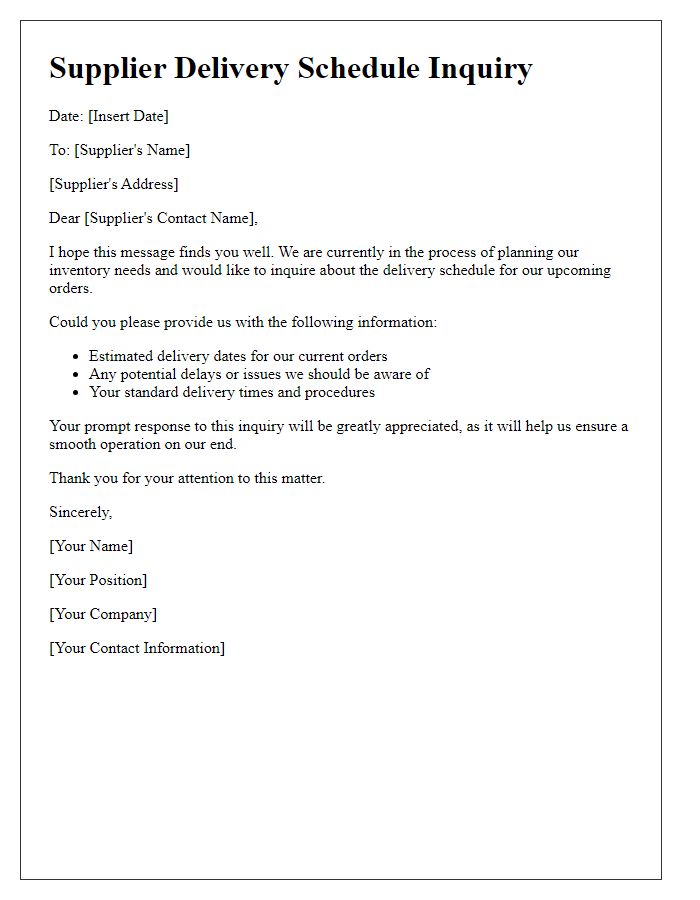

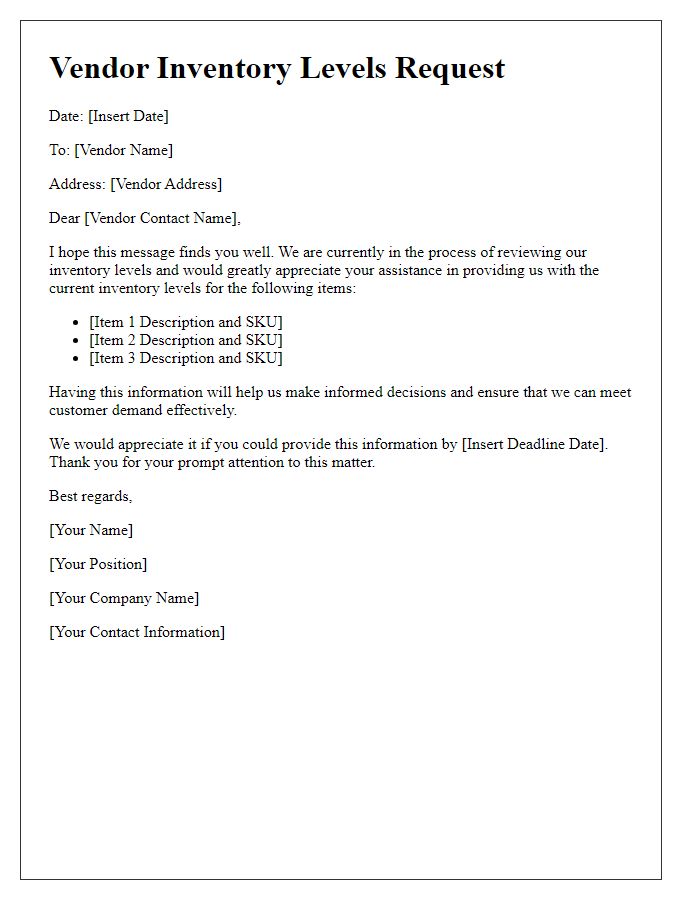

Subject Line

Supplier availability can significantly impact project timelines and production schedules, especially for critical components like semiconductor chips. These chips, essential for electronics such as smartphones and laptops, may experience shortages due to global supply chain issues affecting manufacturers like TSMC (Taiwan Semiconductor Manufacturing Company). Inquiry into available stock levels or lead times for components from suppliers can help organizations like Apple or Samsung effectively manage their procurement strategies. Additionally, understanding the suppliers' capacity to meet demand can prevent delays and ensure timely product launches in competitive markets.

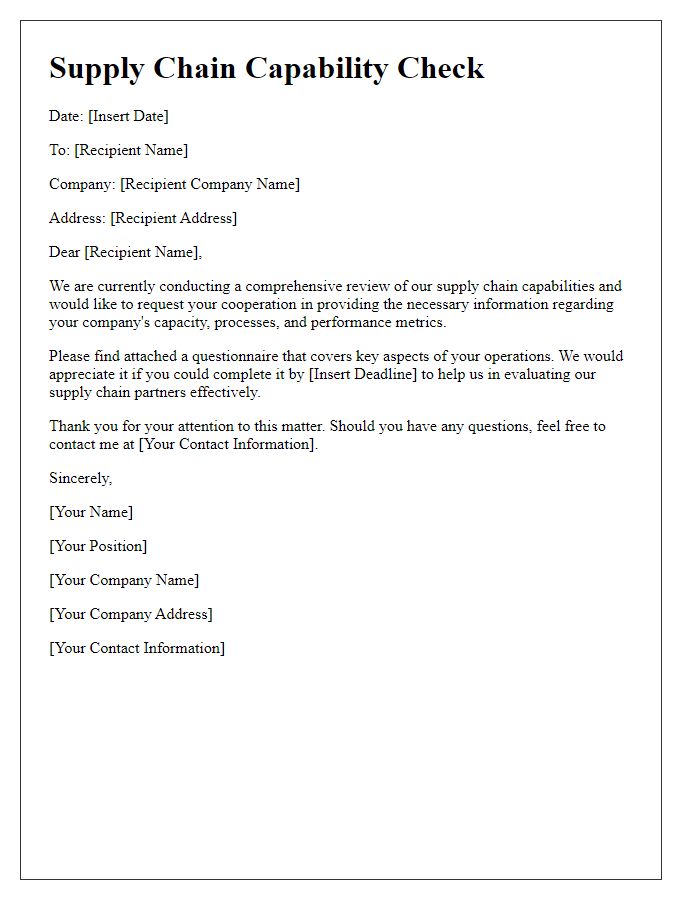

Formal Greeting

The formal greeting sets the tone for professional communication with suppliers. Addressing the recipient by name, such as "Dear Mr. Smith," or "Dear Ms. Johnson," is essential for personalization. Including the supplier's title, if known, adds respect to the greeting. If the specific name is not available, using "Dear Supplier," or "Dear Valued Partner," maintains professionalism. This initial expression of courtesy establishes a positive framework for discussing supplier availability regarding products or services needed to meet operational demands.

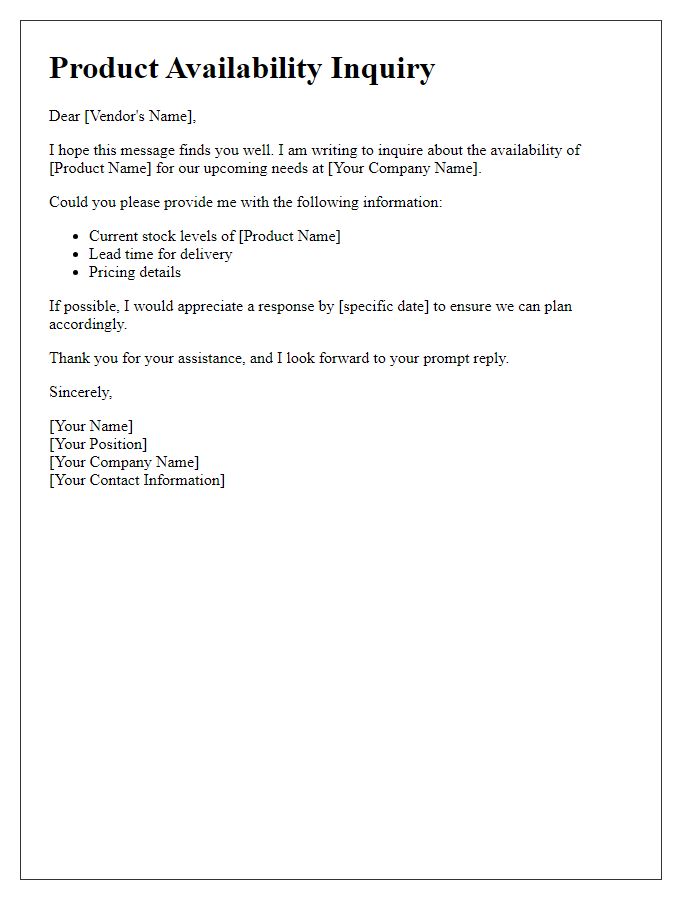

Introduction and Purpose

Inquiries regarding supplier availability are essential to ensure a seamless supply chain, particularly for businesses operating within manufacturing sectors or retail markets. Identifying key suppliers critical to the production process, such as those providing raw materials like aluminum or plastics, significantly impacts operational efficiency. The purpose of the inquiry focuses on determining the current stock levels, lead times for fulfillment, and potential challenges in supply, particularly in the context of fluctuating market conditions that may arise from global events such as pandemics or geopolitical tensions. This information enables companies to make informed decisions regarding inventory management and production scheduling, ultimately supporting customer satisfaction by maintaining consistent product availability.

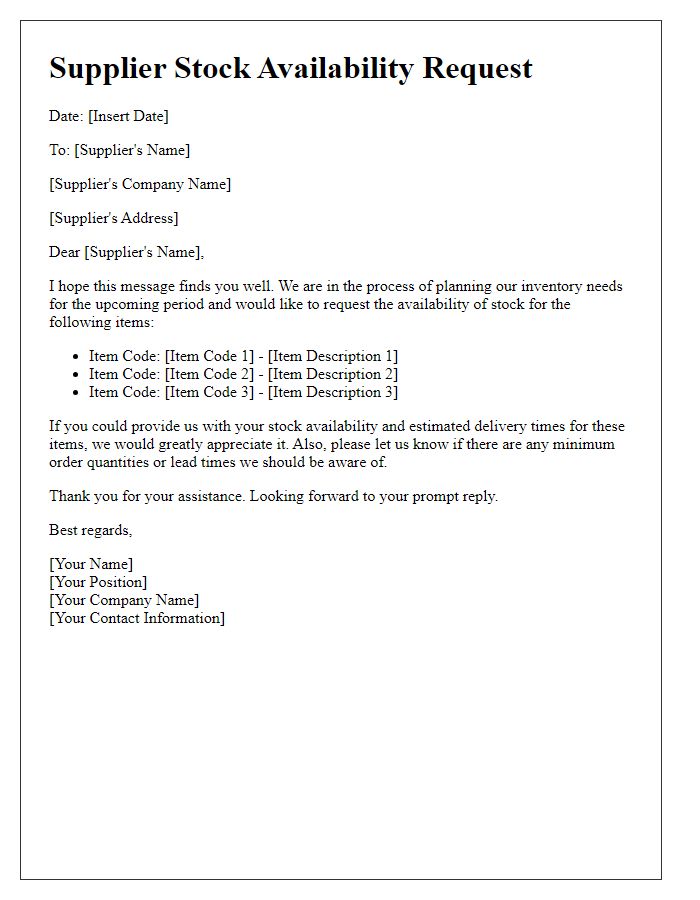

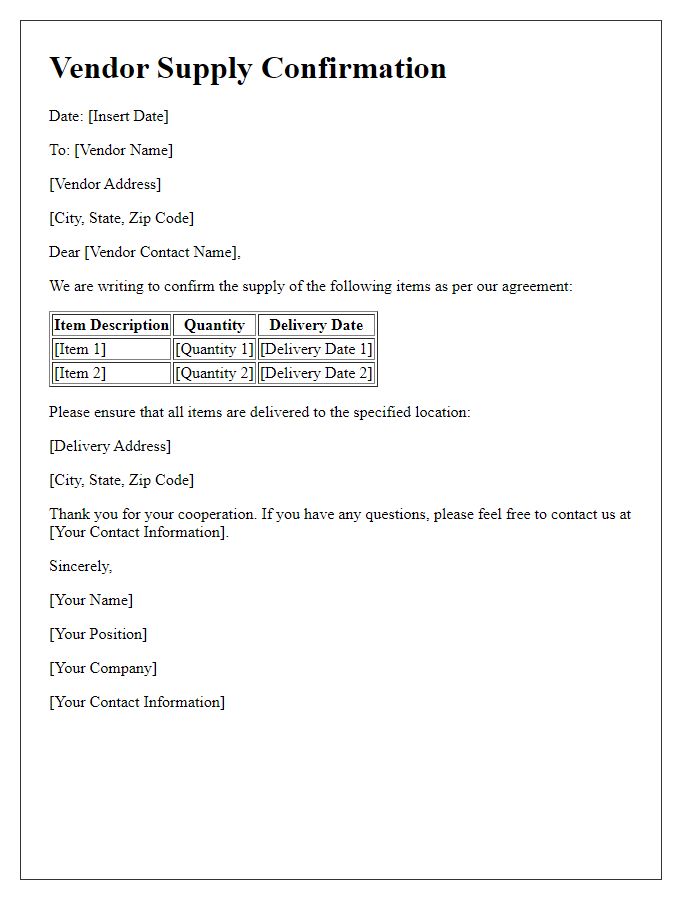

Detailed Request

A detailed request for supplier availability includes specific product information and timelines. For instance, a manufacturer may inquire about the availability of 10,000 units of a specific widget model (Widget-X3000), required for a project starting on April 15, 2024. Additionally, the request could mention desired delivery schedules, such as needing the initial shipment by March 1, 2024, to ensure adequate lead time for quality assurance checks. Key aspects could encompass quality certifications (ISO 9001) relevant to the industry, potential costs, and payment terms. It may also include information on alternative products, like Widget-Y2000, should the initial request be unattainable within specified constraints.

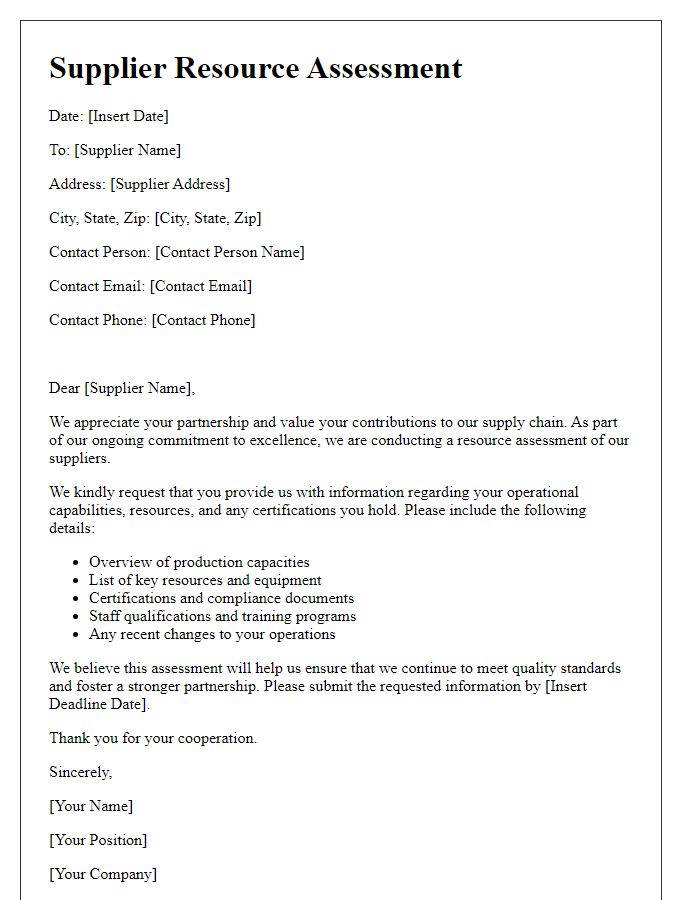

Contact Information and Closing

Inquiries regarding supplier availability are crucial for maintaining a smooth supply chain process. Effective communication ensures that products meet demand without unnecessary delays. In the context of procurement, timely responses from suppliers can minimize stockouts and optimize inventory levels. When reaching out, include essential contact information such as email address, phone number, and company name to facilitate swift communication. Clear and concise closing remarks in your inquiry can lead to a quicker response, enabling better planning and decision-making. Aim to keep the request professional, reflecting the urgency and importance of the inquiry.

Comments