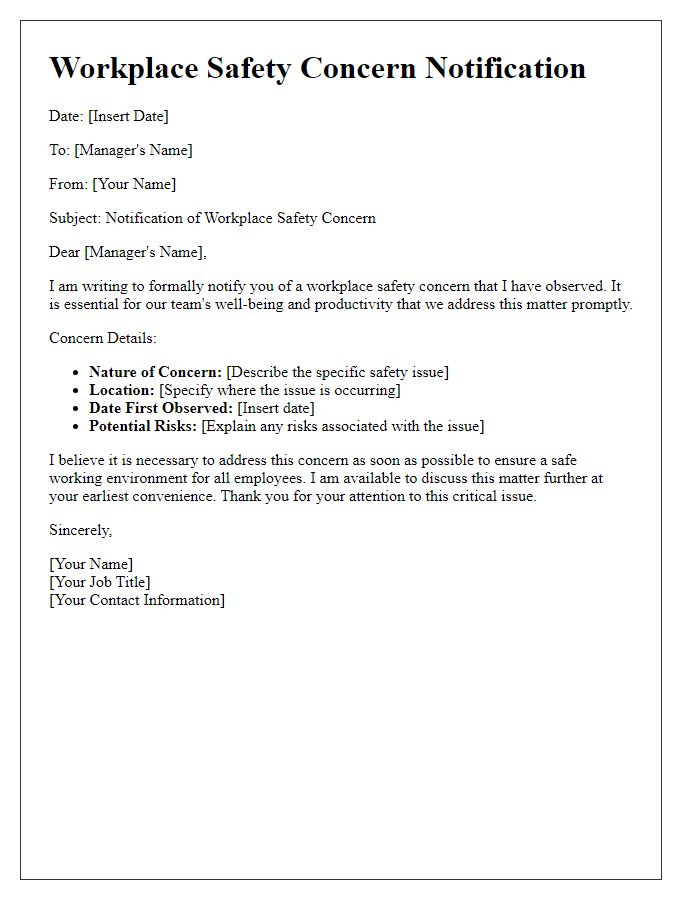

Navigating workplace safety concerns can feel daunting, but voicing them is crucial for fostering a secure environment for everyone. Whether it's a minor hazard or a significant threat, addressing these issues not only protects your colleagues but also contributes to a culture of accountability and care. In this guide, we'll walk you through a straightforward letter template that makes reporting safety issues simple and effective. So, let's dive in to empower you to make your workplace saferâread on to learn more!

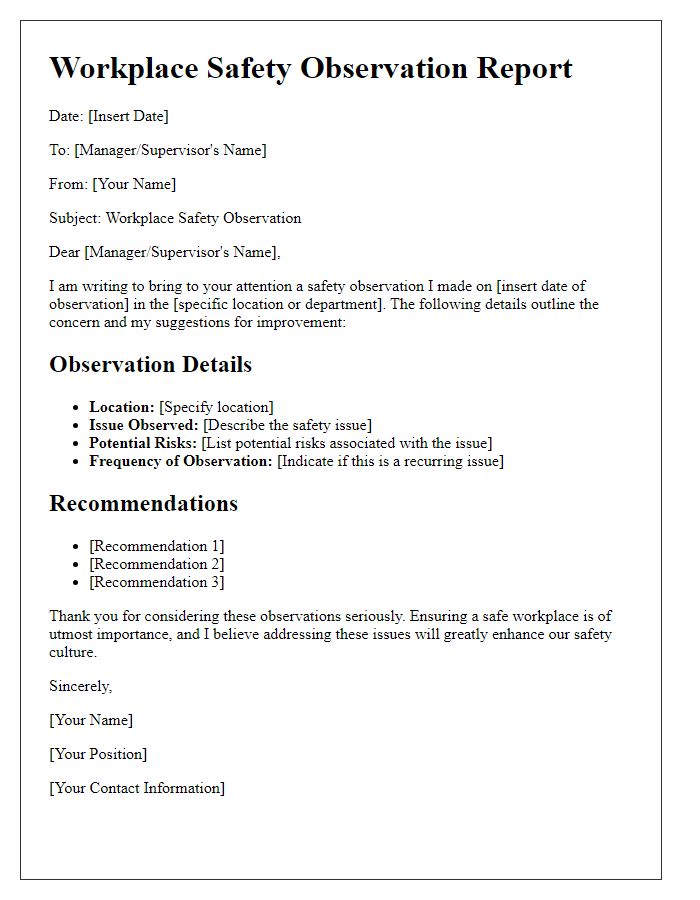

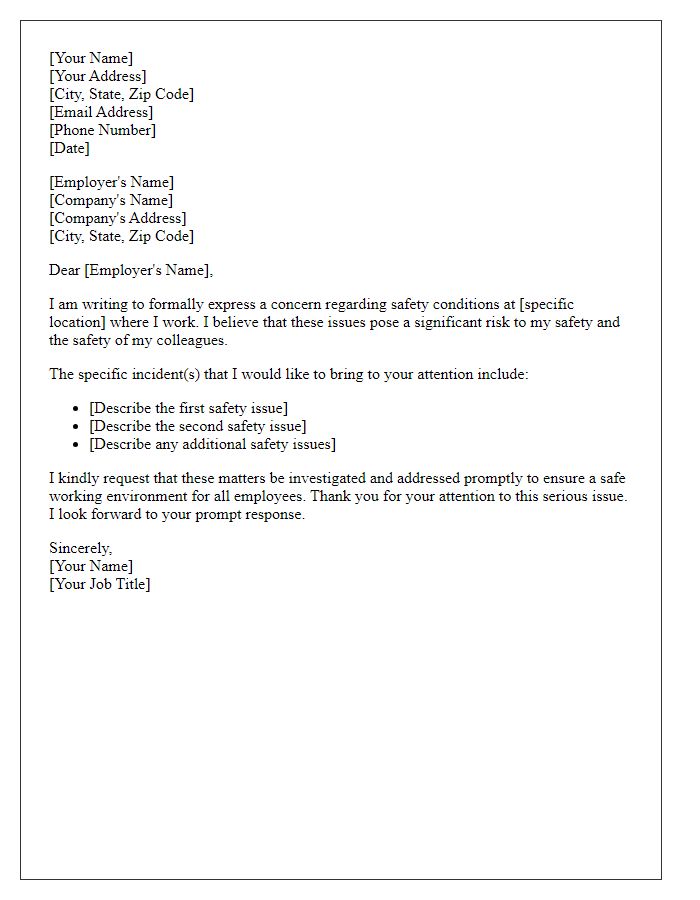

Clear description of the issue.

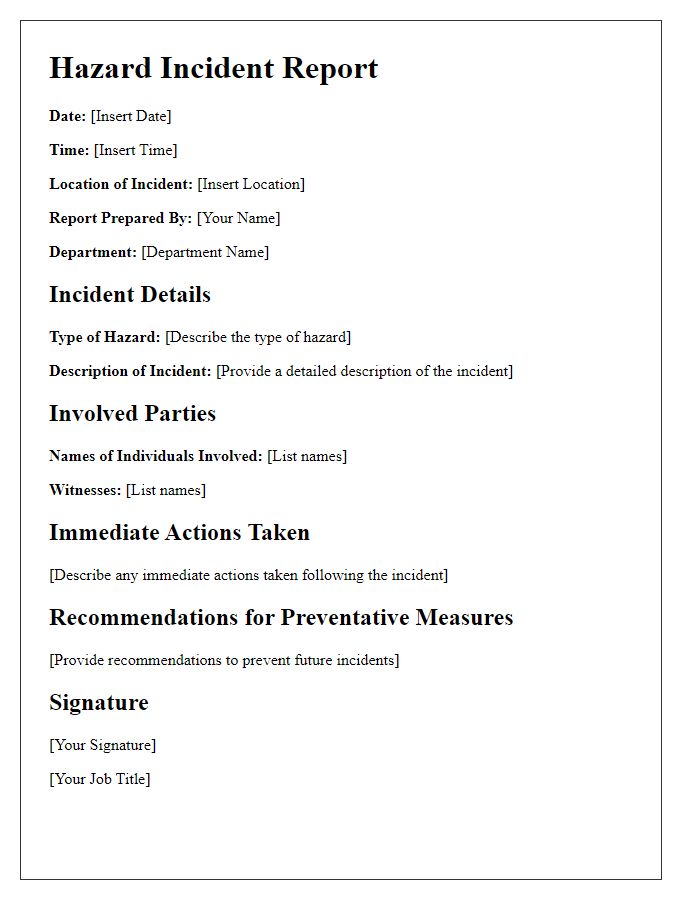

A malfunctioning fire suppression system poses a significant safety risk in the main warehouse of the XYZ Distribution Center, built in 2010. Recent inspections revealed that the automatic sprinkler system (a critical component designed to control fires) has not been maintained adequately, with over 30% of the sprinkler heads showing signs of corrosion and blockages. This deterioration can lead to ineffective response during a fire emergency, significantly increasing the potential for smoke damage (which can affect up to 1,000 square meters of equipment). Furthermore, inadequate emergency exits (only two available for a facility housing more than 200 employees) impede evacuation during a crisis, presenting an alarming DANGER. Immediate action is required to address maintenance issues and ensure safety compliance with OSHA regulations (Occupational Safety and Health Administration), which mandates regular inspections of fire safety equipment.

Specific location details.

A recent assessment of safety protocols at the downtown branch of XYZ Corporation, located at 123 Main Street, revealed potential hazards that require immediate attention. The facility's storage area, particularly sections A and B, is overcrowded with boxes stacked precariously, posing a risk of items falling and injuring employees. Additionally, the lack of proper signage in the main hallway leading to the emergency exits contributes to confusion during emergency situations, where clarity and quick access are crucial. Furthermore, safety equipment such as fire extinguishers has not been inspected within the recommended annual timeframe, leading to concerns about their effectiveness in case of a fire. Addressing these issues promptly can significantly improve workplace safety in compliance with OSHA regulations.

Date and time of incident or observation.

On October 15, 2023, at approximately 10:30 AM, an incident was observed at the manufacturing facility located on Industrial Park Drive, which focuses on assembly line production of electronic components. During the daily safety inspection, it was noted that a significant spill of coolant, approximately 5 liters, had occurred near the machinery section where multiple workers were present. The spill created a slippery surface, posing an immediate risk of slips and falls in an area commonly accessed by staff during shift changes. Proper signage indicating wet floor conditions was absent, exacerbating the potential hazard. Immediate remedial action is required to prevent injuries and ensure ongoing compliance with Occupational Safety and Health Administration (OSHA) regulations.

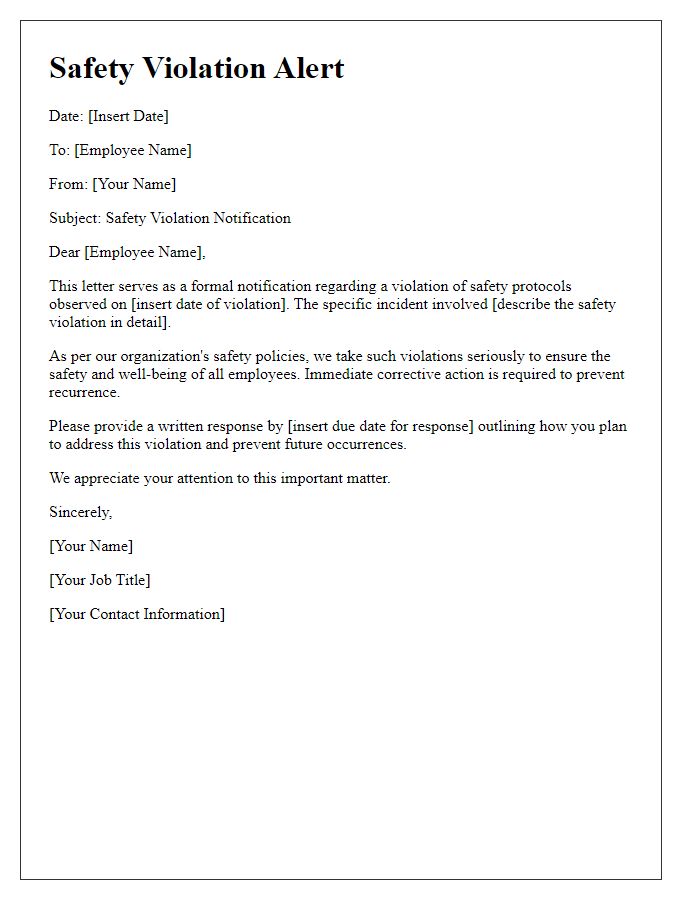

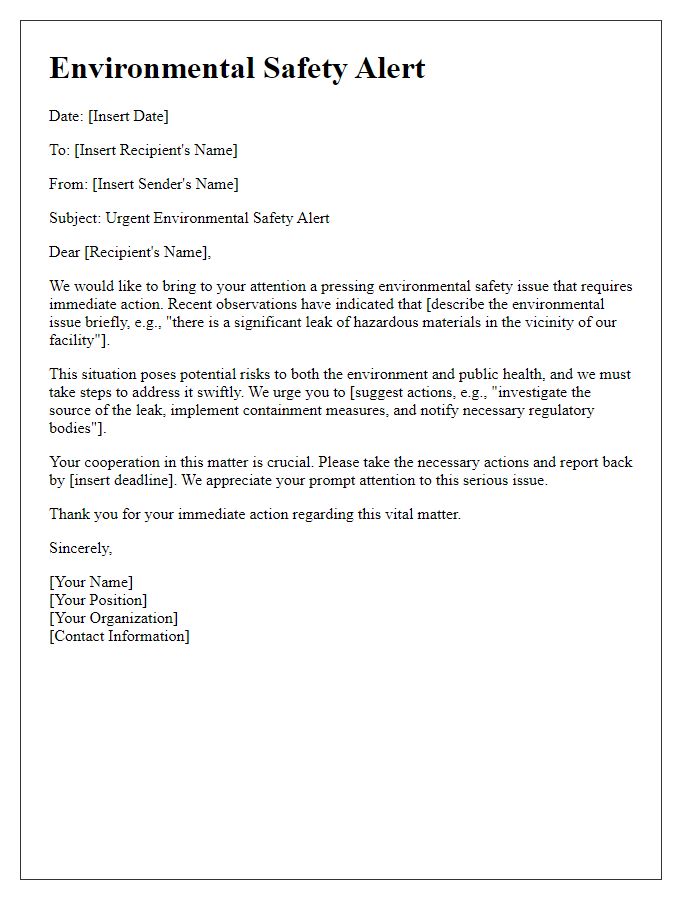

Possible risks or consequences.

Workplace safety issues can pose significant risks for employees and the overall work environment. For instance, unmarked wet floors in busy areas can lead to slip and fall accidents, resulting in injuries such as fractures or sprains. Inadequate fire exit signage or blocked escape routes during emergency drills can increase the likelihood of chaos and injuries during actual fire incidents, putting lives at risk. Ergonomic hazards, such as poorly designed office furniture, can contribute to chronic conditions like carpal tunnel syndrome or back pain among workers. Furthermore, exposure to hazardous materials without proper safety equipment can lead to serious health issues, including respiratory problems or skin irritations. Regular inspections and immediate reporting of potential hazards are crucial for maintaining a safe workplace.

Suggested corrective actions or solutions.

Workplace safety issues require immediate attention for employee well-being. Common hazards include slips, trips, falls, and exposure to harmful substances. Suggested corrective actions may include implementing anti-slip flooring in high-traffic areas, ensuring proper signage for wet floors, conducting regular safety drills, and providing personal protective equipment (PPE) such as gloves and goggles. Additionally, instituting comprehensive training sessions on safety protocols, emergency response, and ergonomic practices will enhance awareness. Regular safety audits and feedback mechanisms can also ensure continuous improvement in workplace safety standards.

Comments