Hey there! We know life can get busy, but it's important to keep your appliances in tip-top shape. That's why we're sending you a friendly reminder about your upcoming scheduled maintenance. Curious to find out how this simple task can save you time and money in the long run? Keep reading to learn more!

Subject Line Optimization

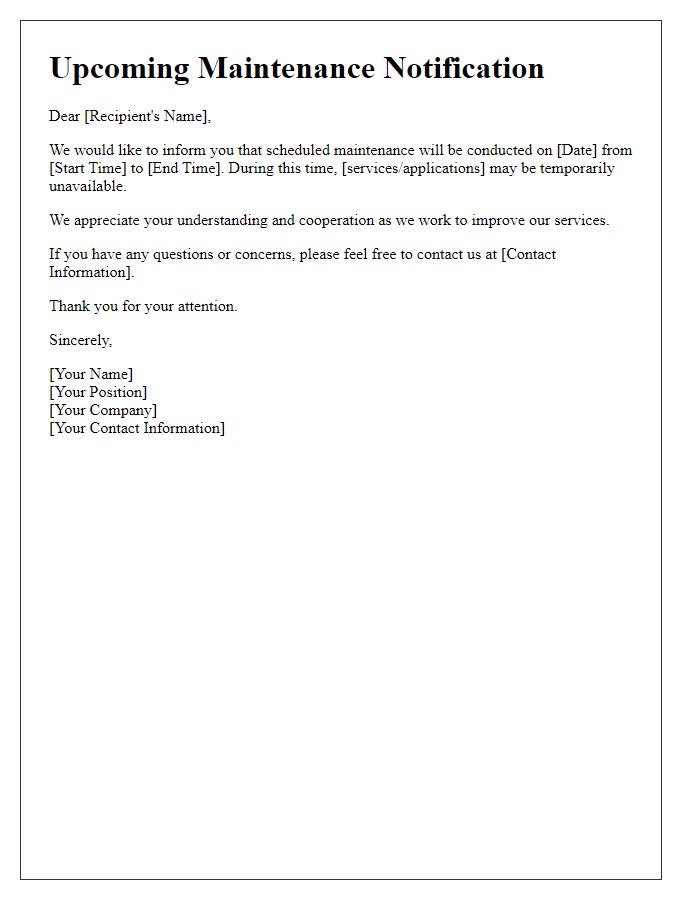

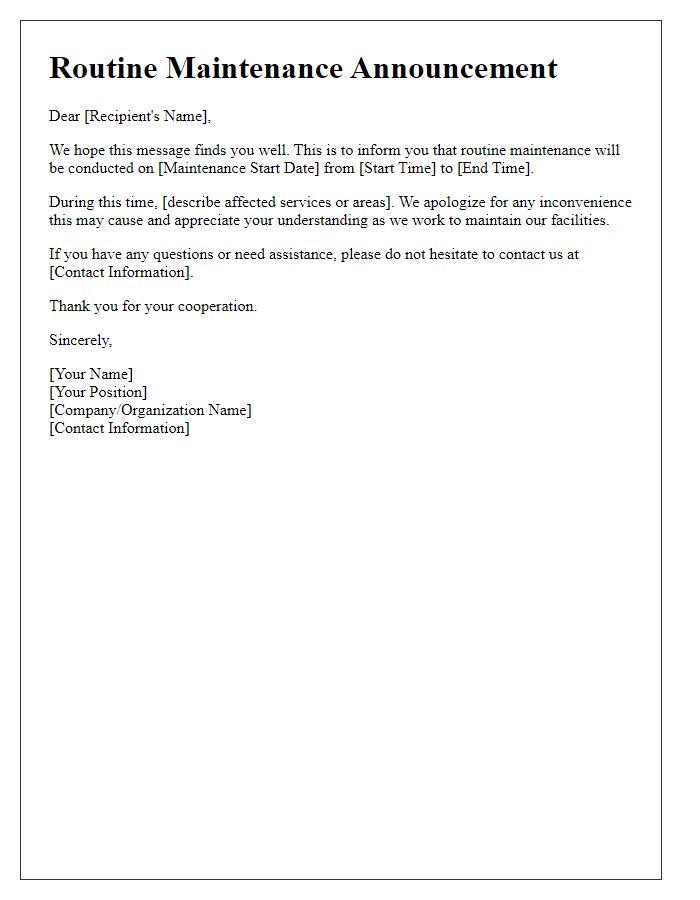

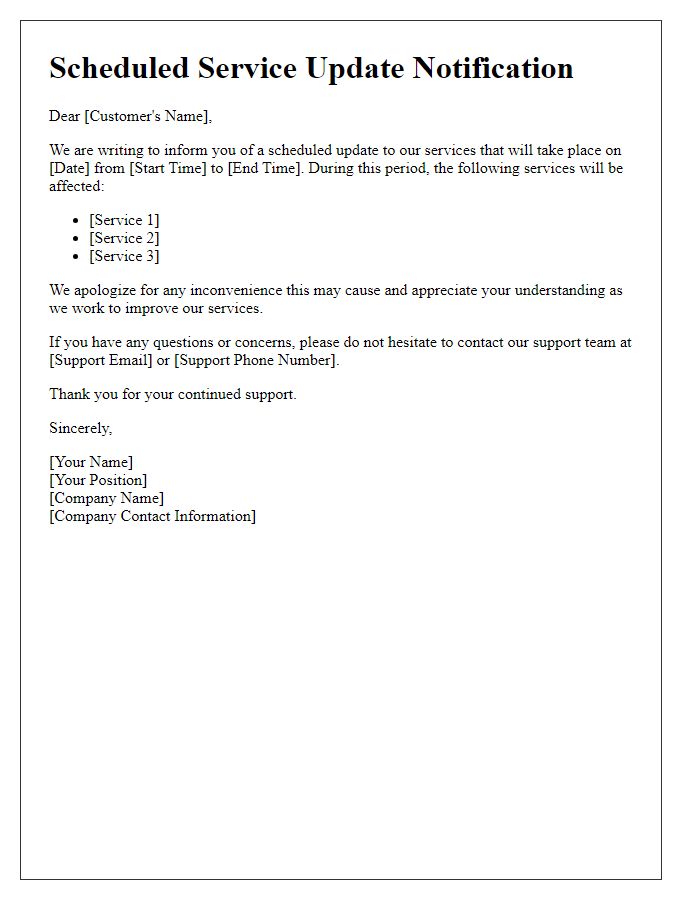

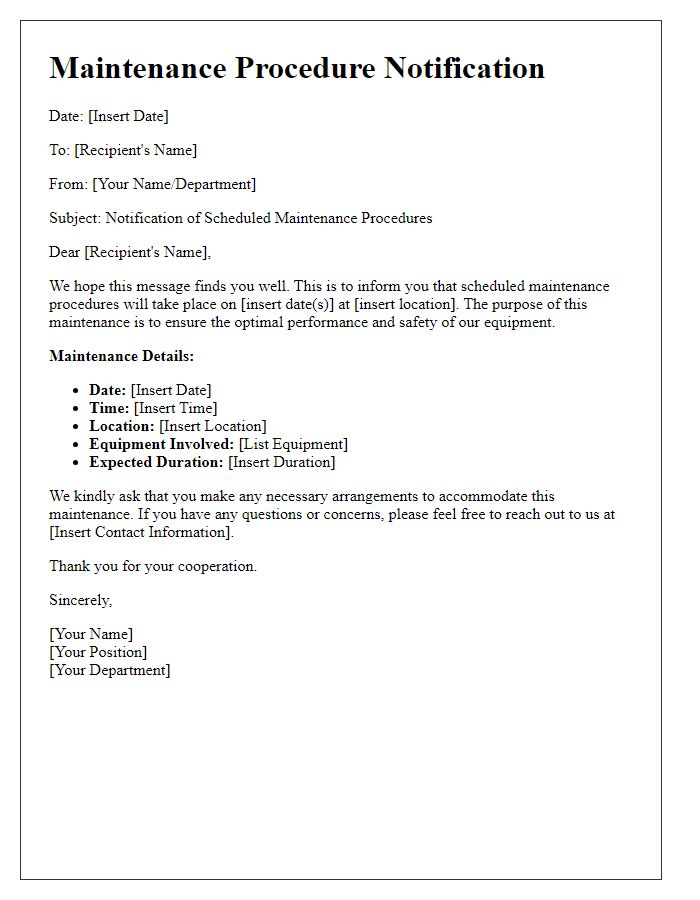

Scheduled maintenance reminders are crucial for ensuring the optimal performance of equipment and services. Effective subject lines must include key details such as the maintenance date, specific equipment affected, and urgency level. For instance, "Scheduled Maintenance Alert: [Equipment Name] on [Date] - Action Required" captures attention while providing necessary information. Mentioning the time frame, like "Reminder: [Service Name] Maintenance Scheduled for [Date] at [Time]" emphasizes the importance of immediate attention to the upcoming maintenance event. Including location specifics, such as "On-Site Maintenance: [Equipment Name] Installation in [Location] - [Date]" helps recipients understand the context and urgency, facilitating timely and informed responses.

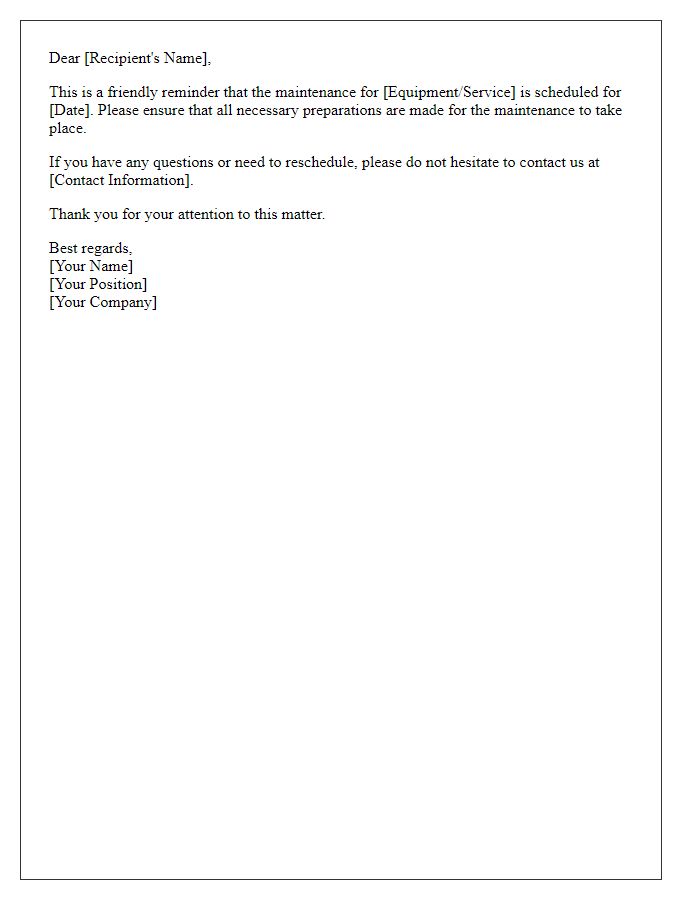

Personalized Greeting

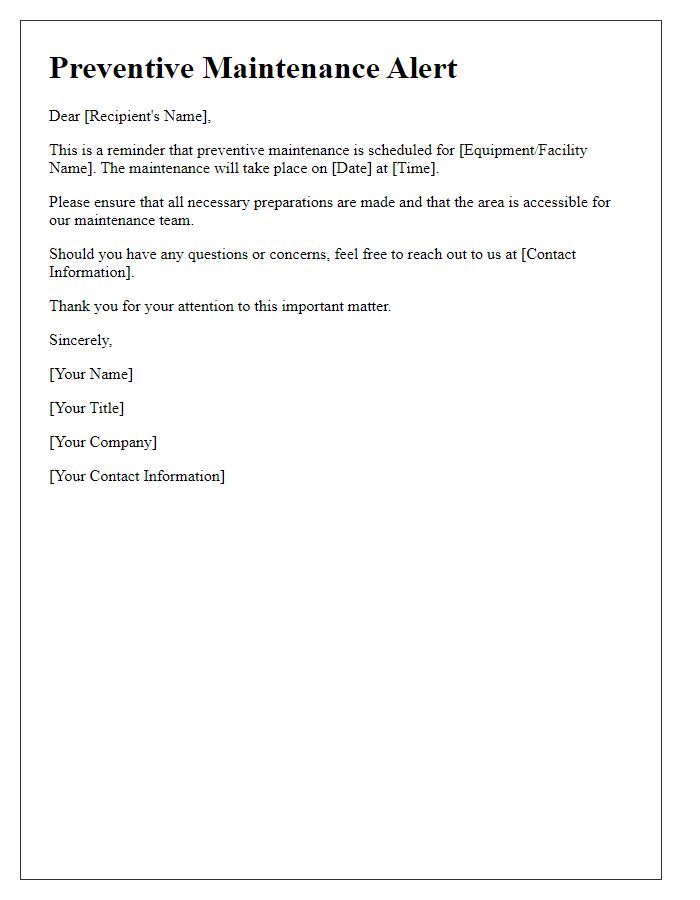

Scheduled maintenance reminders are crucial for ensuring optimal performance and safety of equipment. Regularly scheduled services, such as those performed on HVAC systems, vehicles, or machinery, can prevent breakdowns and extend lifespan. For example, HVAC systems require filter changes every three months to maintain air quality and efficiency. Vehicles often need oil changes at intervals of 5,000 to 7,500 miles to avoid engine damage. Equipment manufacturers recommend specific maintenance schedules based on usage, such as industrial machinery needing annual checks to ensure compliance with safety standards. Consistent maintenance not only enhances performance but also can reduce operational costs significantly by avoiding expensive repairs.

Clear Maintenance Details

Scheduled maintenance plays a crucial role in ensuring the optimal performance of machinery and equipment, specifically in industrial settings like manufacturing plants. Maintenance windows typically occur quarterly, aligning with ISO 9001 quality management standards to minimize downtime. Specific tasks include lubrication of moving parts, inspection of hydraulic systems, and testing electrical components, which are essential for reducing wear and tear. For instance, in automotive workshops, regular checks every 5,000 miles (approximately 8,000 kilometers) involve tire rotations and oil changes to maintain vehicle safety standards. Notifying staff about scheduled maintenance on specific dates enhances productivity and ensures that all necessary tools and spare parts are prepared in advance. Failure to adhere to these schedules may result in costly repairs or equipment failure, leading to delays and decreased overall operational efficiency.

Contact Information

Scheduled maintenance reminders are essential for ensuring the longevity of equipment or services. Companies like [Service Provider Name] often send notifications to their clients, reminding them of important maintenance dates to prevent downtime or malfunctions. For instance, routine HVAC system maintenance should occur every six months, ideally before summer and winter seasons. Ensuring that HVAC systems in commercial buildings (like office complexes located in urban centers) function optimally prevents emergency repairs that can be costly and time-consuming. By providing a clear schedule and contact information in the reminder, clients can easily arrange for necessary services, while maintaining optimal working conditions or comfort in residential and commercial spaces.

Call-To-Action

Scheduled maintenance ensures optimal performance of machinery and equipment, crucial in industries such as manufacturing and transportation. Regular check-ups on systems like HVAC units can improve energy efficiency by up to 30%, significantly reducing operational costs. Facilities like warehouses and factories in cities like Chicago may experience increased productivity following maintenance, extending equipment lifespan beyond the average lifespan of 10 years. Important components, such as filters and lubricants, should be regularly replaced to prevent breakdowns. Timely reminders for maintenance appointments can enhance operational reliability, ensuring adherence to safety standards and reducing unforeseen downtime. Schedule your maintenance today to avoid potential disruptions.

Comments